How does the circulation pump in the heating system. Why circulating pumps are installed in heating systems. Types of circulation pumps

Circulation pumps are devices whose main functions are to pump liquid substances. They are installed when it is necessary to provide forced circulation or recirculation of liquids, and are widely used in heating, cooling, and air conditioning systems. In heating systems, pumps provide uniform heating of all rooms of the building. If in small houses and cottages you can still do without them, then in buildings of a large area - no. How can circulating pumps be used in heating and other systems?

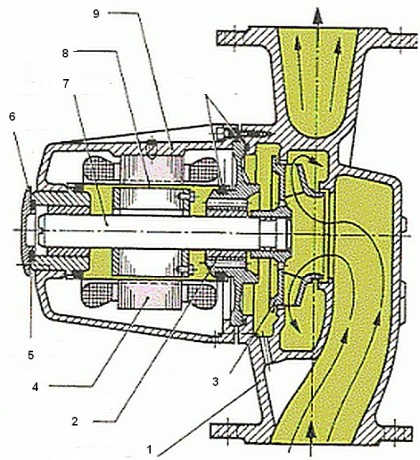

- a rotor, to the shaft of which a vane wheel (impeller) is attached;

- electric motor;

- inlet and outlet pipes.

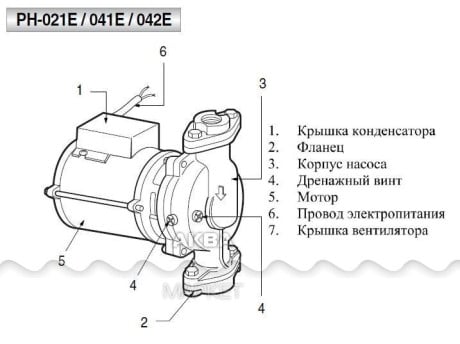

Liquid circulation pump

The body is made of corrosion resistant alloys. The most commonly used cast iron, aluminum, steel, bronze or brass. The electric motor makes the rotor shaft rotate. When the device is turned on, water is sucked in through the inlet pipe, as the rotation of the impeller creates a reduced pressure, and under the influence of centrifugal force is transmitted to the pipe through the outlet pipe. Technical and operational characteristics of the device depend on the diameter and frequency of rotation of the impeller.

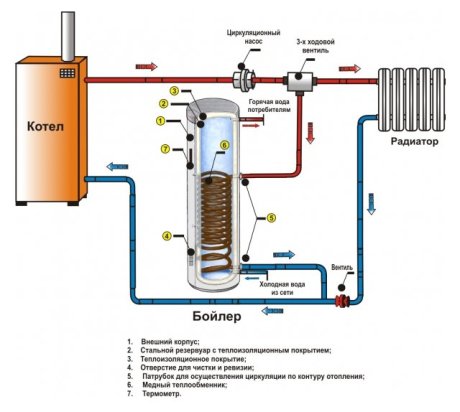

Diagram of a heating system and hot water supply with a circulation pump

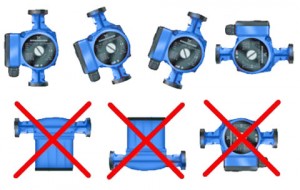

Differences between dry and wet rotors

Depending on whether the rotor is in contact with the liquid, two types of pumps are distinguished - “dry” and “wet”. Each of the species has its own design features and scope.

“Wet” circulation pump: advantages and disadvantages

A “wet” rotor is in liquid, and its stator is protected from moisture by a special stainless steel sleeve. The disadvantage of models of this type is lower efficiency compared to “dry” structures. Advantages - relatively "quiet" work, ease of maintenance and repair.

Modern models are equipped with reliable automation, thanks to which you can easily control their performance, select operating modes and thereby control energy consumption. Circulating pumps with wet rotors are suitable for installation in systems where the amount of fluid is constant or varies slightly.

Design features of the wet rotor model

Features of the work of models with "dry" rotors

“Dry” rotors do not come into contact with liquids, they are closed by o-rings made of stainless steel, ceramic or carbon agglomerate. These elements are carefully adjusted, when they rotate, an aqueous film appears, which protects the details of the electric motor. Rings gradually wear out as the device is used. To provide sealing, use a clamping spring. She clamps the parts, thus constantly adjusting to each other.

During operation, the pump creates air turbulences that lift small particles of dust into the air. If they get inside, they can violate the tightness of the o-rings and spoil the mechanism. A thin water film is needed to prevent dust from entering between the parts of the device. The disadvantage of a “dry” rotor is a noticeable noise during operation. Such models are best placed in separate rooms.

The design scheme of the "dry" pump of the German brand Wilo

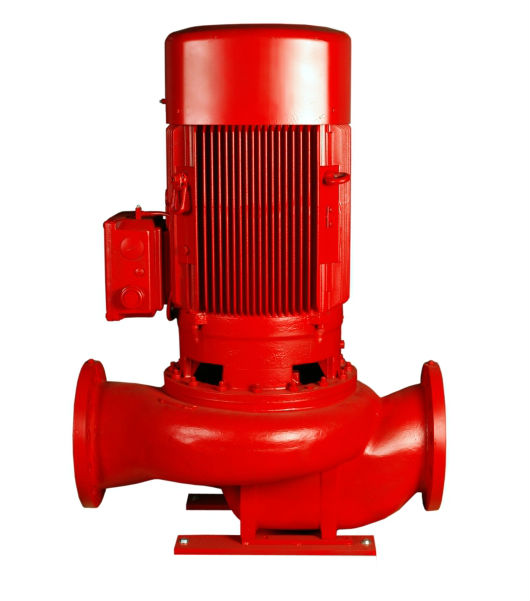

Cantilever, vertical and block dry models

Depending on the design features, three types of “dry” pumps are distinguished:

- vertical

- cantilever (horizontal);

- blocky.

The suction nozzles of the cantilever models are located on the outside of the cochlea, the inlet - from the opposite. The engine is mounted horizontally. Vertical models are named so because their engines are mounted vertically. The pipes in them are located on the same axis. A feature of block pumps is that the liquid enters in the direction of the axis, and exits in the radial direction.

Why circulation pumps are installed in heating systems

Thanks to the forced circulation of the coolant, you can create a more comfortable microclimate in the house. The rooms warm up much faster and better. At the same time, the requirements for boiler power and energy consumption are reduced. Pumps are used both in radiator heating systems, and when installing underfloor heating.

If the model is chosen correctly, the efficiency of the system as a whole increases, and the cost of heating decreases. The only possible drawback is noise during operation, but most often extraneous sounds do not appear due to the pump, but because of errors during the installation of the system or when air enters the pipes.

Simplified scheme for connecting the circulation pump to the heating system

Where else are circulation pumps used?

- In cold and hot water supply systems

Installing a pump allows you to achieve a stable temperature of hot water and a good pressure in the system. You do not have to drain cold water into the sewer, waiting for hot water to go out of the tap. This saves resources.

- In innovative heating systems

Solar and geothermal heating technologies are not yet very common, but pumps are also installed in them for circulation of the coolant.

- In air conditioning systems

Circulation pumps can pump not only hot liquids for heating homes. They are also used for cooling and conditioning.

- In heat recovery systems

The recuperator is a unit that heats the supply air due to the exhaust air. A pump is needed to circulate ethylene glycol in such a system.

Hot water pump

Can I use a circulation pump for irrigation

Difficulties with watering plants is an urgent problem for many gardeners. The circulation pump is universal, so it helps to solve it. As a rule, the "root of evil" is the weak pressure of water. Large volumes of water are needed, but the water supply system is often not able to pump it at the right speed and pressure. By installing a pump, you can provide the desired pressure.

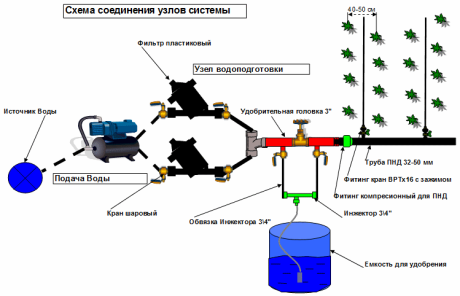

Pumps are used in drip irrigation systems that need a working pressure of 0.2-4 atmospheres. To organize such a system, storage tanks are installed at the elevation and circulation pumps are switched on for several hours a day. This allows for greater irrigation efficiency than with the installation of gravity systems, which often do not live up to expectations.

When choosing a model, pay attention to the main parameters: power, maximum pressure, volume and lifting height of the pumped liquid. If there are difficulties with the calculation, you do not need to buy a pump “by eye”, consult a specialist. As for manufacturers, the Halm, Wilo (Germany), Grundfos (Denmark), Pedrollo (Italy), AlfaStar (Poland) brands have proven themselves in the pumping equipment market. The products of these brands have won the trust of customers around the world. If the budget allows, it is better to purchase models of these manufacturers.

Video: heating using a circulation pump

Residents of apartment buildings do not particularly think about where the water comes from batteries, and how it turns out that it constantly moves with good pressure. But the owners of private cottages, which have autonomous heating, willingly have to be interested in these issues, because the efficiency of the entire installation will directly depend on the quality of transportation of the coolant. Recently, when a new system is being created or an old one is being modernized, a circulation pump for heating is almost always used, and it does not matter if it is installed separately or is part of the boiler.

Why pumping equipment is used in the heating system

When heated in the heat exchanger of the boiler, the water discharges and becomes lighter. It rises and is replaced by denser cold masses. So in the heating circuit there is a natural circulation of the coolant. In some cases, this is enough to transfer heat to the radiators. However, such gravity systems can only function in relatively small houses with an area of \u200b\u200bnot more than 100 square meters, which have a simple layout. Heating without a pump of two-story cottages or buildings of complex configuration is almost impossible to do. Yes, and do not forget about the technical difficulties of natural circulation, since you need to increase the cross-section of pipes in all areas, as well as it is necessary to withdraw to the attic and insulate the expansion tank and lay pipelines with a constant slope (from 3 degrees) towards the heat generator.

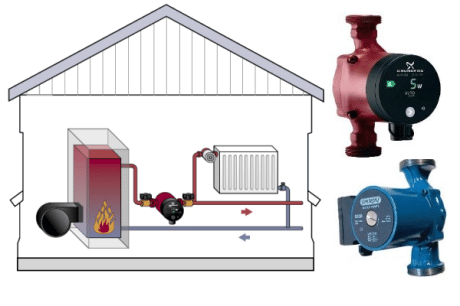

The circulation pump works in any systems, including underfloor heating

In turn, the installation of the pump for heating allows you to organize forced circulation of the coolant. By artificially pumping water, we increase the speed of its movement, due to which substantial hydraulic resistance is overcome by increased pressure. This gives the user a number of practical advantages:

- It is possible to heat large buildings, including multi-story or with a difficult layout.

- There are no cold zones in the structure. Using pumps for heating in individual areas, balance the flow of coolant in all circuits.

- It is allowed to use any wiring diagram convenient for a particular object.

- Pipe routing can be performed in all available ways (in a hidden way in the floor or cavities of the false ceiling, with sharp turns and contraclones).

- Pipes of a smaller internal section are used than in gravity systems.

- The return temperature does not differ so much from the supply temperature, which positively affects the operation and durability of the heat generator.

- The system is less prone to air congestion.

- It is possible to use various types of automation.

- Warming up a cold house is much faster.

- The energy consumption is reduced by 10-15 percent.

Important! There is one unpleasant moment. All power equipment must be connected to the electrical network. Therefore, if a power outage occurs, most systems stop working. Therefore, a UPS for a heating pump (for example, a small gas generator) is required.

The electric boiler and pump are powered through a differential machine on a separate panel

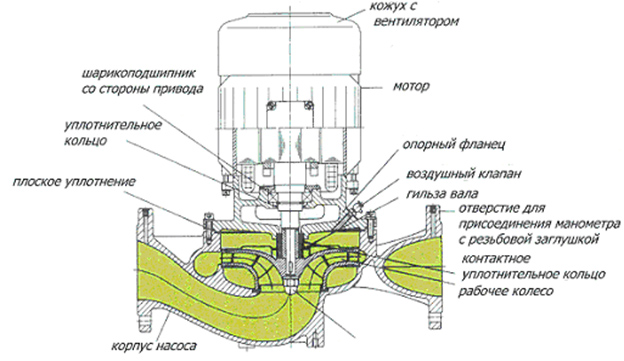

The device and principle of operation of the circulation pump

Types of pumps for heating

Depending on the version, it is customary to distinguish two types of circulation pumps:

- with a dry rotor

- with a wet rotor.

In devices with a dry rotor, the motor parts do not come into contact with the transported liquid, only the impeller is in the chamber with water. Here, to ensure engine cooling, a blowing fan is installed under the casing, and the case itself is endowed with pronounced ribs. These pumps have high efficiency (about 70 percent), which is why they are used in heating systems of large buildings, where you need to transport a lot of water. Due to their high productivity, instead of threaded nozzles, these models usually use flanges for connecting to large diameter pipes. A clear drawback of such injection units is the noise and sensitivity to the dustiness of the room where they are located.

Important! A centrifugal pump for heating with a dry rotor can be positioned in any position.

In dry rotor pumps, the motor and impeller housing can be spaced apart

For pumps with a wet rotor, the shaft contacts the coolant, which for moving parts is both lubricated and cooled. These devices are quieter, lighter and more compact. Due to the relatively low efficiency (about 40%), such products are used only in everyday life - for houses up to 200 square meters, however, their price is much lower.

Important! In order for the bearings to lubricate, the wet rotor pump must be installed in a position where the shaft is oriented strictly horizontally. When working without a coolant in the system, the device quickly overheats.

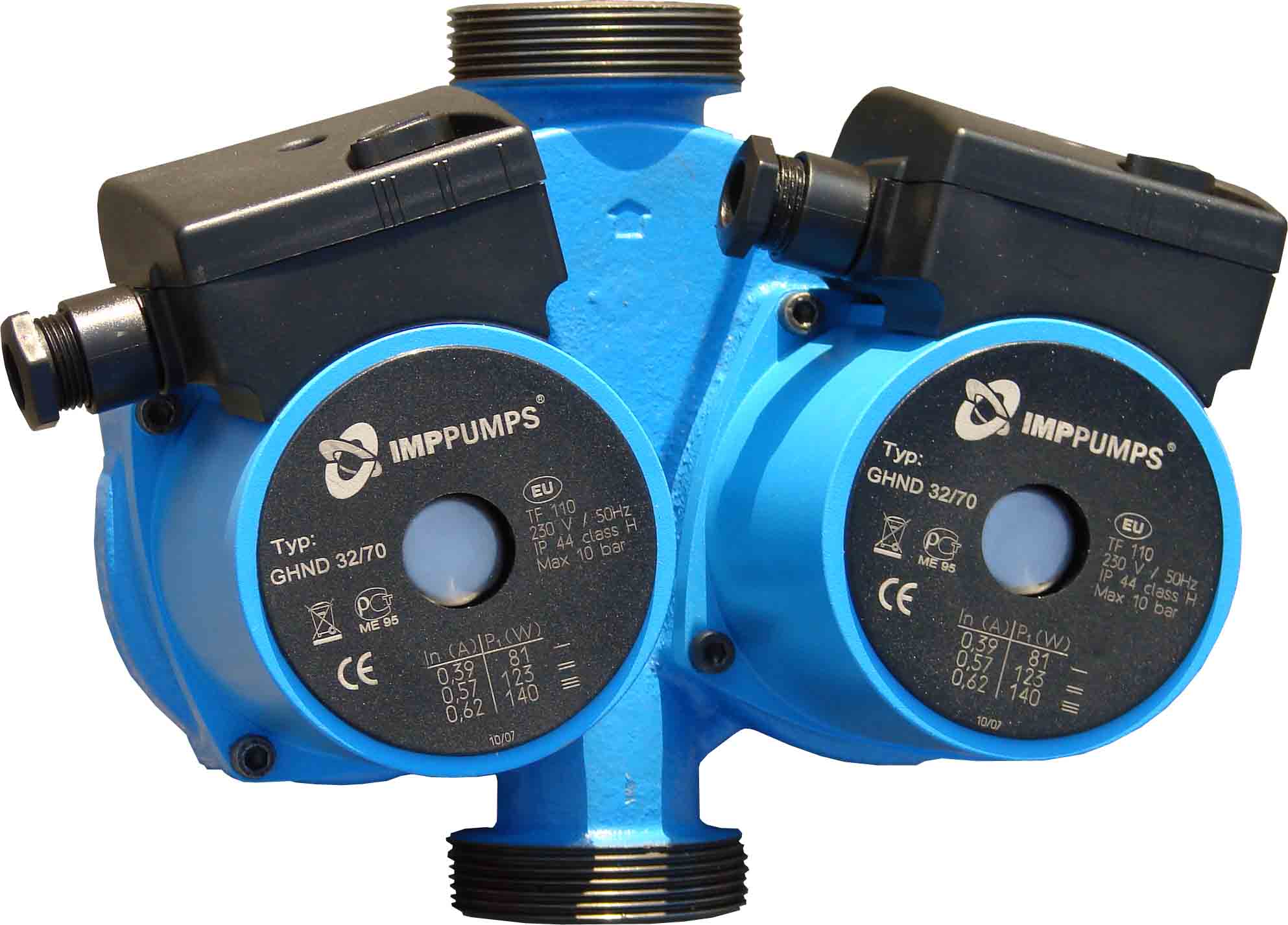

It is interesting that both types of heating pumps can have a double design when the impeller rotates one or two motors, depending on the current operating conditions of the heating system.

The dual pump saves space and allows you to flexibly control the performance of the pressure unit

The main elements of the pumping equipment with a wet rotor

By design, these products are very similar to conventional pumps, such as drainage. The body of the device is usually made of cast iron, sometimes made of brass or steel. On both sides there are threaded nozzles for connecting pipelines.

The electric motor is perpendicular to the direction of the duct. Its stator is energized and separated from the coolant by a sealed monolithic glass sleeve (made from carbon fiber or stainless steel). Power is usually rated at 220 volts, but more powerful products can be three-phase.

Important! There is also a low-voltage brushless equipment at 12 volts (the drive is carried out using permanent magnets), which runs on batteries or solar panels. Basically, these pumps are used as emergency.

The rotor shaft is made of ceramics or stainless steel, it is mounted on mechanical bearings and goes into the working chamber of the housing, filled with pumped water.

An impeller made of heat-resistant polymer, which is equipped with radially curved blades, is fixed on the motor shaft. The impeller captures water and directs it towards the outlet pipe. The cavity around the wheel has a complex section (confuser), which allows you to collect and drain water in the right direction, as well as convert kinetic energy into static pressure. So, compression is formed at the outlet, and a vacuum is formed in the area of \u200b\u200bthe inlet pipe, which contributes to the absorption of the coolant.

Under the aluminum casing of the electric motor on the pump housing for heating, there is a control board, outside there is an insulated terminal box for switching power wires. On the front side there is a speed switch (there are three of them in the bulk of the devices). To discharge air from the working chamber, either a vent or a special screw plug is used.

Some models come with additional useful options:

- indication of the wheel;

- thermostat

- a timer for setting the operating modes during the day;

- thermal relay for protection against overheating;

- built-in flowmeter;

- frequency converter (automatically changes the speed of rotation of the impeller).

How to choose a circulation pump for heating

First of all, you should decide on the performance of the equipment. Water consumption is measured in cubic meters per hour. Calculation of the pump for heating is carried out according to the formula Q \u003d N / (t2-t1). That is, the power of the heat generator (N) is divided by the difference in water temperature at the supply and return. For example, if a 15 kilowatt boiler is needed for a house, and the temperature difference is 10 degrees, then the pump should pump about 1.5 cubic meters - 1500 liters of liquid per hour, or 25 liters per minute.

The second key indicator is pressure (meters of water). That is, we need to calculate the maximum working pressure so that the coolant overcomes the hydraulic resistance of the system. We will have to find out what are the total losses of the system in all areas, what can be done if hydraulic calculations are performed. For a private house, this figure is usually about 2-4 meters of water.

All the main characteristics of the equipment are indicated on the "facade"

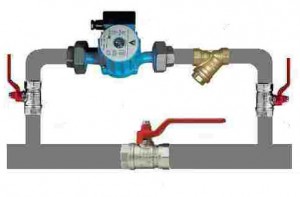

Some features of connecting the pump to heating

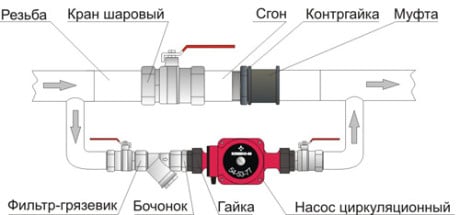

In most cases, the injection equipment is mounted on the return pipe near the boiler. It is necessary that the direction of movement of the coolant coincides with the location of the inlet and outlet pipes (there is a hint in the form of a relief arrow on the pump casing). Models with a wet rotor should be installed so that the motor shaft is in a horizontal position. The device is not tied up alone - a coarse filter should be installed in front of the pump, possibly a control pressure gauge.

On both sides, the assembly is separated by taps so that there is an option to carry out maintenance or replacement of elements without draining

When a combined system with natural and forced circulation is implemented, the pumping group for heating is located on the bypass line, which allows, if necessary, to cut off the power equipment. In any case, if you are not sure about your preparation, hire professionals to install the pump.

Video: overview of the circulation pump for heating

Circulation pump performs the function of forced circulation of the coolant in heating systems of closed and open types. Circulation pump consists of a stainless steel housing, to which an electrical part is mounted, consisting of a stator winding, inside which a rotor is inserted.

Of course, the heating system, with a built-in circulation pump, is more efficient, since the heating of a small house is carried out within a few minutes after starting the heating boiler. Competent installation of a circulation pump heating system will significantly increase its efficiency and make such a system more economical in terms of energy consumption (as practice shows, gas savings will be about 25-30%). What is the reason for saving? The heated coolant will be supplied faster to the radiators and returned to the boiler faster, less chilled, and the warmer coolant will be heated faster, the load on the boiler will be reduced, which will also be less likely to turn on.

Types of circulation pumps

By design features circulation pumps are divided into mechanisms of "wet" and "dry" of type.

Pump design feature dry type lies in the fact that the rotor is not in direct contact with the coolant, since its working surface and electric motor are separated by special sealing stainless rings. A thin film of water located between the rings, during rotation, seals the connection due to the pressure difference in the external environment and the heating system. The clamping spring performs a constant compression of the rings as they wear and ensures their "self-adjustment". The efficiency of dry type circulation pumps is 80%. However, pumps of this type are quite noisy and more demanding in service, in comparison with wet pumps and are rarely used in individual heating.

Wet Circulating Pumps differ from “dry” ones in that the rotor together with the impeller are in direct contact with the coolant, which cools the device and at the same time acts as a lubricant. In pumps of this type, the rotor and stator are separated by a special "glass" made of stainless steel, which ensures the tightness of the electrically powered part of the motor. All parts of the wet circulation pump operate in the pumped medium.

The efficiency of such pumps is about 55%, however, they are less noisy and unpretentious in maintenance. Their performance is quite enough for systems of small lengths, so they are most often used in individual heating.

How to choose a circulation pump for a heating system

Choosing a circulation pump indicators such as its capacity, pipeline diameter, heat carrier temperature, coolant pressure level, productivity and throughput of the boiler are taken into account.

Circulation Pump Parameters displayed in its marking. For example, marking 25-60 - what does it mean? 25 is the diameter of the connection size in mm., In this case it is 1 inch, and 60 is the pressure or the height of the lift. In this case, the lift height is 6 meters water column or 0.6 atmospheres.

Any circulation pump has three power levels. Each power stage is characterized by its performance, that is, the volume of coolant that pumps the pump in one hour.

Circulating pump performance directly depends on the length of the pipeline (as a rule, when calculating, 10 m / p of the pipeline accounts for about 0.5 m of pump head). Also, one should not forget that the narrower the cross-section of the pipes in the system, the greater the resistance the coolant will experience.

The flow rate of the coolant is calculated simply by equating it with the power parameters of the heater. For example, with a boiler power of 25 kW, the flow rate of the coolant will be 25 l / min. Radiators with a power of 15 kW require 15 l / min of water.

With the length of the pipeline of the heating system not more than 80 m., It will be enough to install one pump, with a longer length of the pipeline, it is necessary to install two or more circulation pumps.

Circulation pump installation - installation features

The first thing to do before installation of a circulation pump - determine the installation location. It must be taken into account that circulation pump needs periodic maintenance, so it should have free access to itself.

The most optimal place for its installation, in front of the boiler, on the return pipe. The thing is that over time, air can accumulate in the upper part of the boiler and when the pump is installed at the supply, air will be drawn out of the boiler, which will lead to the formation of vacuum and boiling of the air-conditioned part of the boiler. If the pump is installed in front of the boiler, then it will push the coolant into it, which will not lead to the formation of air jams. In addition, such an installation system provides for the operation of the circulation pump at lower temperatures (the return temperature of the coolant is always lower than at the supply), and this extends its life.

|

A very important installation point is the position of the circulation pump shaft. The shaft must be located in a strictly horizontal position, otherwise the pump will not be completely in the water, and in the best case it will lose up to 30% of its productivity, and in the worst case, the working area may fail due to overheating. |

|

It is recommended to install a so-called bypass (bypass line) on the selected installation site of the circulation pump. Bypass is necessary so that in the event of a power outage or a pump failure, the coolant circulates through the opening of the taps through the main pipeline, and the heating system continues to work already in. |

It must be remembered that the diameter of the bypass pipe (bypass) must be less than the diameter of the main pipeline.

Before the pump, it is necessary to install a coarse filter, which will protect the rotating elements of the mechanism from small mechanical particles. It is especially undesirable to get debris on the impeller, which can simply jam, which will lead to the combustion of the winding and the failure of the pump.

On both sides of the pump it is necessary to install shutoff valves (ordinary ball valves). Having blocked them, if necessary, it is possible to carry out dismantling or maintenance without completely draining the coolant from the system.

It will be even more correct to use a check valve instead of one of the ball valves.

If a non-return valve is used, it can also be removed if necessary. circulation pumpBy blocking only one ball valve, a check valve installed in the direction of the arrow will not allow the coolant to flow out from the other side of the pump.

Another function that the non-return valve performs, especially with high risers on the flow line, is to prevent the backflow of pressure in the system. What does it mean? If a vertical riser of large length "comes out" upward from the boiler, then the pressure will be directed not only upwards, but also due to the forces of gravity, pressure will be directed downward. Here, so that part of the pressure does not go into the “return”, and the system “stops” and a check valve is installed.

- Private house heating

- Security group

Circulation pumps are used in heating systems and hot water supply (hot water). The principle of operation is based on the forced circulation of the fluid through the enclosed space of the pipeline.

Such pumps are used in heating systems of multi-storey buildings and country cottages. Due to the use of circulation pumps, the rooms warm up faster and more evenly than when using the natural circulation of the coolant, where hot water is supplied through a vertical pipe (riser) due to the method of natural convection.

1 Description, device, principle of operation of the circulation pump

According to the device, the circulation pump, in fact, is similar to a drainage installation. In the case from stainless. steel, cast iron or aluminum (sometimes - bronze, brass) built-in rotor made of ceramic or steel. The rotor shaft is equipped with a wheel with impeller blades. A wheel with blades is most often made of technopolymer.

The action of such a device is due to the principle of centrifugal force, which is formed during the operation of the impeller. The movement of the coolant is carried out by capturing it on one side and forcing it into the pipeline on the other. Vacuum is generated in the suction pipe during the rotation of the impeller. Vacuum is responsible for the continuous process of circulating and supplying water to the suction pipe.

Water in such a mechanism can circulate at a speed of 2 m / s in domestic applications (to avoid vibration and noise and pipes) and up to 8 m / s in industry. The pumps are powered by electrical energy, which is their advantage. After all, such a device, used in the industrial field, consumes no more than 0.3 kW, in the household - up to 85W.

A heating system using circulation pumps is able to efficiently heat rooms with any configuration of piping, with pipes of small diameter, including those built into the floor or walls.

The advantages of using this type of pump include:

- fast heating of the room;

- creation of a separate temperature regime in each room by means of a thermal relay;

- installation of the boiler anywhere;

- the ability to adjust the rotor speed, which reduces energy costs;

- minimum number of air jams.

1.1 Types of circulation pumps

Two types of circulation pumps are produced: “wet” and “dry” (with wet and dry rotor).

For the “wet” type, it is characteristic that the rotor is located directly in the fluid that is being pumped. The electric motor is located in a sealed part, where water does not get. The principle of operation of this mechanism is as follows: a rotating rotor accelerates the movement of water. The fluid in which the rotor is located is a cooler and lubricant for the mechanism.

Wet rotor mechanisms are used in heating systems with a relatively small piping length.

Advantages of the “wet” type of pumps:

- low noise level;

- simplicity in changing settings;

- stepless change of rotor speed;

- long period of service;

- lack of need for maintenance.

The main disadvantage of this type of device is the low level of efficiency (not exceeding 50%). The reason for the low productivity is that it will be practically impossible to seal the sleeve that separates the stator from the pumped liquid with an increase in the diameter of the rotor.

In a “dry” type pump, the rotor does not come into contact with the coolant. Its working part is isolated from the engine by means of o-rings, which are made of coal sinter, ceramic or stainless steel.

Such pumps are more efficient. In the process, the O-rings self-adjust and rub against each other. The period of their service is not less than 3 years. The efficiency is about 80%. But at the same time, running pumps with a dry rotor make a lot of noise, which is why they need to be installed in separate rooms with sound insulation. You also need to consider the environment of the room in which such units are located. In the process, they create air turbulence, dust can rise up and penetrate into the system, which leads to damage to the surface of the seal rings.

2 Popular Manufacturers

Due to the great demand for these products, dozens, if not hundreds of enterprises around the world produce different types of circulation pumps. Therefore, I propose to review the products of some foreign manufacturers - manufacturers, as well as pumps manufactured in Russia.

2.1 Salmson NXL

The French company Salmson is part of the industrial group WILO AG. Today, under the Salmson brand, a wide range of pumping products is produced, which has such characteristics as reliability, high quality, compliance with European standards.

Salmson circulation pulsers are used in central airs, water supply, heating, ventilation. Their distinguishing feature is that the rotor is practically not subject to contamination, since the water entering it passes through the filter.

In addition, the products of this series are characterized by the versatility of the model range, low noise, high quality and low cost. The pumps are equipped with a bronze casing, which makes it possible to use them for drinking water systems.

2.2 Wester WCP 25-40 G

Household surface circulation pump with nuts. Used for heating, air conditioning and underfloor heating. It can pump hot water, chemically non-aggressive fluids or fluids with a viscosity of not more than 2 sq.mm / s.

It has a “wet” rotor, manual three-stage switching of the number of revolutions.

The body is made of cast iron, the impeller is polymer.

Specifications:

- power - 93W;

- max head - 6m;

- throughput - 2.7 m3 / h;

- max temperature of the passed liquid - 110 ° C;

- max ambient temperature - 40 ° C;

- accession - 1 inch;

- max working pressure - 10 bar.

2.3 Vaillant 160928

The Vaillant circulation pump is used for operation of gas boilers ATMOmax and TURBOmax, as well as in heating and domestic hot water systems.

It supplies the coolant to the heating system or to the secondary heat exchanger. In the latter, heating of cold water occurs.

Vaillant has first and second degrees of rotation speed with the ability to manually switch. Manufacturers recommend keeping the pump in the second stage, since there will be greater thermal power of the water supply and less time for heating the water. The unit is switched to the first stage when it is necessary to reduce the noise level during its operation.

2.4 Vortex BWZ 152 ½

This German-made equipment is suitable for heating systems and water supply systems. The Vortex circulation pump can pump hot water, chemically non-aggressive liquids or liquids with a viscosity of not more than 2 sq. Mm / s, ethylene glycol with a concentration of not more than 40%.

Features:

- “Wet” rotor;

- three-position speed control;

- union nuts are included;

- case - cast iron;

- impeller - polymer;

- motor case - aluminum;

- silent process of work;

- small dimensions.

Index Z indicates the presence of a daily mechanical timer with a time step of 15 minutes.

Power - 0, 025 kW, power - 230V, 50 Hz.

2.5 Lowara TLCSOL

The Lowara TLCSOL circulation pump with a wet rotor is used in solar systems (systems with solar collectors).

Pumps are characterized by silent operation, as well as simple installation, which makes it possible to install them in any room. The kit additionally includes 2 union nuts and a heat-insulating cover.

Characteristics of Lowara TLCSOL circulation pulsers:

- country of origin - Italy;

- pumped liquid - water;

- voltage - 230V 50 Hz;

- max water temperature - 110 ° C;

- min water temperature - -10 ° C;

- case - cast iron;

- impeller - composite material;

- bearings - ceramics.

2.6 ATSML 1000

Russian-made single-stage centrifugal circulation pumps ATSML 1000 are used in heating, water supply, fire fighting, irrigation and chemical production systems.

They are characterized by low noise and high efficiency. There are various modifications to shaft seals. Transported liquid - pure water; liquids that are similar in characteristics to water; slightly aggressive and aggressive fluids.

Specifications:

3 How to choose a circulation pump?

If you need a circulation pump, when choosing it, you should pay attention to the main characteristics: performance, pressure, coolant temperature, noise level, and also how much electricity it consumes.

Under the performance of the circulation pump understand the amount of distilled liquid. It is recommended that the pump pump over a volume of water equal to three volumes of the heating system per hour. It is recommended to choose a unit with a capacity of 10-20% in stock. Then it will not wear out for a long time and the premises will warm up enough in the winter.

Also, the pump must provide sufficient pressure to overcome the resistance of the pipeline, raise the fluid to the desired height, overcome all the bends of the heating system.

It is also necessary to clarify the temperature of the pumped liquid and correlate it with similar characteristics of the unit, as well as the type of coolant - water or antifreeze.

When considering the issue of energy consumption, it should be borne in mind that some of the most modern pumps consume less energy than a conventional light bulb. In addition, the automatic regulation of heating devices will help you save energy. In this case, the circulation pump will operate intermittently. A special sensor will show when the coolant temperature has dropped below the set line and will start the pump.

The life of the pump will depend on how correctly you determine all the characteristics of the pump for your heating system.

3.1 Circulation pump for heating: device, operation, installation (video)

The circulation pump is one of the main components of the heating system and hot water supply. It is a compact device with suction and discharge functions, which is mounted directly in the heating system pipe. It is designed to provide forced movement of fluid in a closed loop, i.e. circulation as well as for recycling. Thanks to the use of the circulation pump, all rooms in the house are heated much faster and more evenly than when using the standard natural circulation system. Currently, the prevailing construction of country houses, cottages and other structures having an area of \u200b\u200bmore than a hundred square meters. To create a comfortable microclimate in them under any climatic conditions, it is necessary to use circulation pumping equipment.

The arrangement of circulation pumps is similar to drainage pumps. The case is made of stainless alloys (steel, cast iron, aluminum, brass or bronze); rotor rotated by electric motor made of ceramic or steel; the rotor shaft is equipped with an impeller called an impeller. When the pump is operating at the inlet, a pressure-lowering phenomenon occurs, which contributes to the absorption of water. Due to the rotation of the impeller, a centrifugal force occurs, as a result of which compression occurs on the outlet pipe and water is pumped into the pipeline of the heating system.

Pump types

There are 2 types of circulation pumps - “wet” and “dry”.

In wet-type pumps, there is no contact of the rotor with the pumped water, since it is separated from the electric motor by means of metal or ceramic o-rings. In the operating mode of the engine, the o-rings rotate relative to each other, and between the polished and fitted surfaces of the rings there is only a barely noticeable layer of water film, which seals the connection due to the difference in atmospheric pressure and pressure in the heating system. During operation, the sealing rings wear out even more against each other, thereby ensuring the tightness of the rotor for at least 3 years

In this design, the lubrication and cooling functions of the running engine are provided by the coolant. These pumps are supplied with both single-phase and three-phase motors, in proportion to the power of the equipment. For ease of installation in the heating system, the pumps are equipped with threaded or flange connections, which depends on the performance of the pump.

The advantages of wet pumps are:

- silent operation;

- small dimensions and weight;

- profitability of electricity consumption;

- uptime

- simplicity of setup and repair. The modular design of modern “wet” type pumps greatly facilitates their repair, as a faulty module is replaced with a new one at a time.

The only drawback of these pumps is the low level of efficiency (less than 50%). The reason for this is the impossibility of sealing the rotor with a larger diameter. As a result, they are used in the design of heating systems of small length (household systems).

A prerequisite for the smooth operation of “wet” pumps is their proper installation, assuming a strictly horizontal shaft position. It is this arrangement that allows water to enter the bearings through the liner.

The "dry" type circulation pumps are designed so that the rotor does not come into contact with the coolant. Unlike wet pumps, their efficiency reaches 80%. However, they are endowed with a number of disadvantages:

- high noise level. For their installation you need a separate room with good sound insulation.

- demanding for cleanliness of the coolant and indoor air. Since air-borne turbulence occurs during operation of dry-type pumps, which can attract dust particles, they, in turn, can damage and impair the sealing of the o-rings. Therefore, it is necessary to control the level of dust in the air of the room in which the pump is installed, and monitor the composition of the coolant.

There are three types of “dry” pumps:

- horizontal or cantilever, characterized by a horizontal arrangement of the engine, with a suction pipe at the end of the "snail", and a discharge pipe located radially on the housing.

- vertical, with the electric motor in a vertical plane, and the nozzles in the same axis.

- blocky.

How to choose a pump for various heating systems?

It is very important to choose a circular pump, taking into account all the features of the heating system of a particular house, building, structure. To ensure comfortable conditions for staying in a living room, it is necessary, first of all, to calculate the necessary amount of heat, which will provide the optimal microclimate in it. Such calculations are made by heat engineers. At the same time, such indicators as the region’s climate, wall material, insulation of walls, roofs and floors, window characteristics and the ventilation system used are taken into account. As a result, the volumetric flow of the coolant in the heating system is calculated, measured in cubic meters / h.

In addition, when choosing a pump, its pressure characteristics are also taken into account. This parameter is equal to the sum of the hydraulic resistance of the entire heating system. On average, this indicator is 2-4 meters of water. An important parameter in the selection of the pump is also an indicator of the pump flow rate, determined by the dependence of the power of the heat source on the temperature difference of the water in the supply and return piping.

If you select a pump in a house with an existing heating system that needs to be reconstructed, preference should be given to adjustable circulation pumps. It is these pumps that have the ability to automatically adapt to the changing operating conditions of the system. In addition, they are economical and noiseless.

Mounting Features

Installation of the circulation pump is usually carried out by specialists. But there is a category of people who like to do everything with their own hands. Therefore, it will be useful to voice some basic rules for installing circulation pumps.

- Installation of pumping equipment is carried out on the return line near the boiler, where the lowest temperature parameters of the coolant are. If the house or apartment does not exceed 200 sq.m. in area, this rule is conditional for them, since with such a length of the pipeline, the temperature of the coolant in the supply and return flow area will vary by 2-3 degrees. Therefore, the location of the equipment will not be limited.

- When installing the pump, it is necessary to position it so that the arrow on the housing coincides with the movement of the coolant. The pump is strapped using two shut-off valves, a coarse filter at the inlet and a check valve used in cases where a hydraulic accumulator is provided in the system. Threaded connections are treated with sealants.

- If the circulation pump is mounted in a heating system with combined circulation, an additional bypass is formed - a pipe section with a shut-off valve installed parallel to the pump, which will allow the heating system to switch to natural circulation mode if necessary to repair the pump.

- After installing the pump in a horizontal position, fill it with coolant, open the central screw and remove excess air.

Manufacturers, prices, specifications, reviews

When all the necessary data are calculated, you can proceed to the selection of the pump. The easiest way is to choose and buy a pump from the catalog, as it allows you to compare both the characteristics of the pump and other characteristics associated with the installation and operation of the pump. The major manufacturers of circulation pumps for domestic and industrial heating systems are the well-known brands “DAB”, “Lowara”, “Ebara” and “Pedrollo” (Italy), “Grundfos” (Denmark), “Wilo”, “Halm” (Germany) , "AlfaStar" (Poland) and others. Domestic manufacturers offer a series of industrial pumps, and there are no domestic circulation pumps among their products.

The circulation pump for heating Wester, which is popular among consumers, deserves special attention. It is in his address that you can hear good reviews regarding the optimal ratio of price and quality. Grundfos recycling pumps are also widely distributed among private developers and homeowners. Despite the relatively high cost, they are distinguished by reliability, ease of maintenance and durability.

The price of circulation pumps is quite variable, and depends on the power, type of pump, as well as the manufacturer. The cost of medium-power pumps in the domestic market ranges from $ 65 to $ 215.

The heating system of each house, apartment, other building is individual and endowed with a number of its own characteristics and requirements for it. However, it is difficult to imagine a modern heating system without a circulation pump, which allows to increase the level of comfort and convenience of any home.

Since the pumps are mass-produced and equipped with average parameters, it is sometimes difficult to choose exactly what fully corresponds to this heating system. In this case, you should choose a pump model that has several operating modes, which will allow you to experimentally determine and set the most optimal mode in which the pumping equipment will work as efficiently as possible.