Osmosis water treatment. Industrial reverse osmosis and membrane desalination ZauberROS series. Functional features and capabilities.

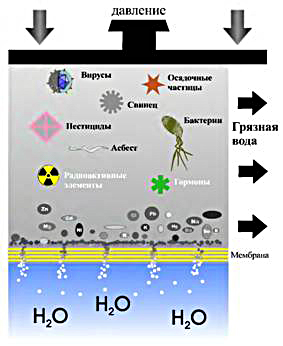

Today reverse osmosisis the most advanced technology. It is based on the use of a reverse osmosis membrane, which is able to purify water from virtually any impurities existing in nature.

The use of membranes to separate some components of a solution from others has a very long history. Even the ancient Greeks first discovered that sea water is desalinated if it is passed through the walls of a wax vessel.

Contamination occurs when contaminants accumulate on the surface of the membrane, effectively clogging the membrane. However, with proper pre-treatment, you will minimize the need to regularly resolve pollution problems.

Contamination may be caused by the following. Particles or colloidal matter. Organic microorganisms. . The most popular pollution prevention methods are using multimedia filters or microfiltration. In some cases, filtering the cartridges will be sufficient.

In the early 60s of the last century, industrial installations already existed that desalinated sea water using reverse osmosis membrane technology.

Improvement of reverse osmosis technology made it possible to use water filters based on it not only in industrial, but also at home. Thanks to this, thousands of similar systems have already been installed around the world, allowing you to get drinking water with the highest degree of purification. Water received at the outlet of reverse osmosis systems is recognized as environmentally friendly. In its properties, it is close to the meltwater of ancient glaciers.

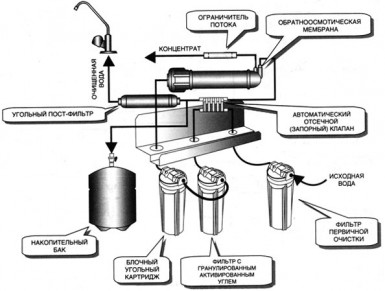

What is included

As some of the dissolved compounds become more concentrated, scaling may occur if these compounds exceed their solubility limits and are deposited on the membrane surface in the form of a scale. The scaling results are a higher pressure drop in the system, a higher salt passage, a lower permeate flow and lower water quality in the permeate.

Modern thin-film composite membranes do not transfer to chlorine or chloramines. Oxidizing agents, such as chlorine, will “burn” holes in the pores of the membrane and can cause permanent damage. If “heavy starts” occur, mechanical damage to the membranes may occur.

The process of the water filter with the installation of a reverse osmosis system.

Reverse osmosis filters are connected to the water supply, from where the source water for cleaning comes, and all impurities are discharged into the sewer system. The operation of the water filter with the installation of a reverse osmosis system includes the following steps:

Reverse osmosis systems: interesting video

A multilayer filter usually contains three layers of medium consisting of anthracite coal, sand and garnet, with a carrier layer of gravel at the bottom. These are medications of choice due to differences in size and density. Larger coal of anthracite will be on top, and heavier garnet will remain at the bottom. The location of the filter material allows you to remove the largest dirt particles near the upper part of the carrier layer, with smaller particles of dirt remaining deeper and deeper in the medium. This allows the entire layer to act as a filter, which can significantly extend the filter's operating time between backwashing and more efficient particle removal.

- water pretreatment

- water passage through a reverse osmosis membrane

- purified water storage

- finish water treatment

- bottled purified water through a separate tap

Stage water pretreatmentis of great importance. The most expensive replacement element of the system is a reverse osmosis membrane. Its service life directly depends on the quality of the water entering the filtration system. At the pre-treatment stage, three filters are used, their task is to prepare water before it passes through the reverse osmosis membrane. The first mechanical five-micron polypropylene filter purifies water from undissolved particles of at least 0.5 microns in size, removes rust, sand and other mechanical impurities. Next, a carbon filter purifies water from chemical and organic impurities, primarily from chlorine and its compounds, as well as pesticides, petroleum products, heavy metals, dissolved iron and other organic and inorganic substances. The last single-micron mechanical filter removes solids less than 1 micron in size.

A multilayer filter that uses coagulant addition can remove particles up to 5-10 microns. To imagine this in perspective, the width of a human hair is about 50 microns. Microfiltration is effective for removing colloidal and bacterial substances and has a pore size of only 1-10 microns. The configuration of the membranes may vary between manufacturers, but the type of “hollow fiber” is most commonly used. Typically, water is pumped from outside the fibers, and pure water is collected from within the fibers.

Microfiltration membranes used in drinking water usually work in a "dead end" stream. In a dead end stream, all water supplied to the membrane is filtered through the membrane. Filter cake, which must be washed periodically from the surface of the membrane. Recovery rates typically exceed 90 percent on feedwater sources, which are of fairly high quality and low turbidity.

In the second stage of the filter reverse osmosis membraneproduces basic water treatment. The processes of water purification through reverse osmosis membranes under the influence of pressure differences are widely used throughout the world. Water purification occurs by filtration through one or more artificial porous membranes made of synthetic materials twisted into a roll. The pore size in the membrane is 0.0001 microns, respectively, only water molecules pass through the reverse osmosis membrane. This allows you to divide the flow of incoming water into two: crystal clear water entering the storage tank and an aqueous solution of high density, which merges into the drainage system. At the same time, the membrane passes oxygen and other gases dissolved in water that determine its taste. As a result, at the output of the reverse osmosis system, fresh, tasty, so pure water is obtained that does not even require boiling.

Antiscarants and growth inhibitors

Antioxidants and scale inhibitors increase the solubility limits of dysfunctional inorganic compounds. By increasing the solubility limits, you can concentrate the salts further than would be possible, and therefore achieve a higher extraction rate and work with a higher concentration ratio. Antiscansants and scale inhibitors work by preventing the formation of scale and crystal growth.

Sodium bisulfite

Granular Activated Carbon

Chlorine or chloramines end as a chloride ion, which is no longer an oxidizing agent. These data include system pressure, flow rate, quality and temperature. Water temperature is directly proportional to pressure. The normalized fluxes, pressures, and salt deviations should be calculated, compared, and compared with baseline data to help resolve any problems and determine when to clean or inspect membranes for damage.High-quality cleaning takes some time, so the performance of reverse osmosis filters is relatively small. The rate of passage of molecules through the membrane depends on a number of factors, the most important of which are the pressure of the liquid, the concentration of impurities in it, the temperature and the degree of permeability of the reverse osmosis membrane itself. Household filters are equipped with membranes with a capacity of 150 to 300 liters per day.

It has been proven that cleaning from the surface of the membrane is more effective while providing better cleaning than the cleaning sled in place. Reverse osmosis is an effective and proven technology for the production of water, suitable for many industrial applications that require demineralized or deionized water.

Is reverse osmosis the best filter for your home?

In my opinion, there is usually no answer. Reverse osmosis is best suited to solve the two problems for which it was originally designed. What is then the best water filter for your home or office? Why reverse osmosis may not be the best water filter for you.

Filtered water accumulates in storage tank volume from 4 to 12 liters (depending on model and filter performance). As pure water is used, the filter automatically adds a new portion of filtered water to the tank. Storage tanks are made of high-quality sheet steel, enameled on the outside. Inside the tank is divided into two chambers by a silicone membrane. Air is pumped into the lower chamber under pressure, due to this, as the water decreases in the upper chamber, the silicone membrane swells and the pressure is maintained in the tank until the water is completely drained. A nipple is installed on the side of the air chamber, which allows, if necessary, to regulate, increase or decrease the air pressure in the storage tank. A thread is installed on top of the tank, where the valve of the storage tank is screwed, for supplying and withdrawing water.

Reverse osmosis has a reputation as the ultimate water purification technology. This is often associated with its use in a military theater. Although reverse osmosis water filters reduce a fairly wide range of contaminants, such as dissolved salts, lead, mercury, calcium, iron, asbestos, and cysts, it does not remove some pesticides, solvents, or volatile organic chemicals, including.

To be completely confused, try and search the Internet for a final list of which reverse osmosis pollutants can remove or try to compare different living systems of different manufacturers next to each other. So much depends on the design of the system, the maintenance and the source of the raw water, which can be a real problem in determining the expected performance and protection that the reverse osmosis system can offer for residents and your family or colleagues.

Postfilterserves as an additional guarantee of the purity of the drinking water received, which comes from the tank, through an individual tap directly to the consumer.

Tap for purified drinking watercrashes into a kitchen sink or countertop and serves to obtain clean drinking water regardless of the total flow of water used for household purposes.

It is known that, despite the fact that reverse osmosis as a technology has the ability to remove certain contaminants in the laboratory; a commercial system, especially a residential system, may not have the same capacity. Reverse osmosis is not the easiest or most cost-effective technology.

Most reverse osmosis systems require a constant flow of water to clean and flush their membranes. This water is disposed of as wastewater. The amount of water produced by the drinking system is called the extraction rate. Careful attention should be given to maintaining reverse osmosis water filtration systems.

Separately, at the request of the customer, the reverse osmosis filter system can be supplemented with cartridges to enrich the purified water with minerals and restore the natural structure of the water.

Mineralizer- enriches water with minerals such as magnesium, sodium, calcium. Calcium is the main component in the composition of teeth, bones and is necessary for the full and healthy functioning of the heart and neuromuscular system. Magnesium is involved in more than 300 different biochemical reactions of our body, prevents sclerosis, the formation of kidney stones, and the appearance of cancer. Sodium is an element that regulates the acidity in the body and the pH of the blood.

Is reverse osmosis demineralized water or even distillation good for you? According to the World Health Organization, the low water produced by reverse osmosis or distillation is not suitable for long-term human consumption and can actually create negative health consequences for those who consume it. This lack of minerals also contributes to the terrible taste that is known for reverse osmosis water. Stay tuned for the news on our next blog post that will focus on the negative health effects of demineralized water caused by reverse osmosis and distillation.

Bioceramic cartridge- used to restore the natural structure of water. Cartridge loading - baked clay balls with tourmaline mineral that emits waves from the long-wave infrared range. Infrared radiation is a part of the solar radiation spectrum, which is directly adjacent to the red part of the visible region of the spectrum and has the ability to transfer energy to the environment. Under the influence of additional energy of long-wave infrared radiation, water molecules form the correct natural structure. The deep infrared radiation (Far Infrared Radiation) produced by the cartridge, due to its properties, is often referred to by specialists as the "ray of life." Water passing through a cartridge with bioceramic material has a beneficial effect on people, animals and plants, activates somatic cells, stimulates blood circulation and improves metabolism (metabolism). The main properties of FIR rays: the activation of water particles that are in the human body, the removal of fats, chemicals and toxins from the circulatory system, the improvement of the nervous system, the decrease in the acidity of the body, and the increase in oxygen level.

Do you have reverse osmosis systems in your home or office? We will be happy to hear about your experience! The ads for the system and the recommendations we received for it never mentioned it. Our home renovation efforts focused on promoting green and green building and materials, and we donated all of our old kitchens for recycling. Why doesn't he fill the tank and then stop until the tank needs to be refilled? Contact those for whom you bought your system for help. Thank you for your inquiry, but it looks like you need the help of a local water purifier that specializes in water softeners.

- Now we collect wastewater in buckets and use them to clean toilets.

- Our water bills decreased significantly when we started this practice.

- I'm afraid that we do not sell water softeners.

Frequently asked questions about reverse osmosis:

How much water per hour can be cleaned with a reverse osmosis membrane?

from 5 to 11 liters, depending on the type of membrane installed.

What is permeate?

Purified reverse osmosis membrane water.

How much water does the concentrate drain?

About 2/3 of the total volume of the water flow goes into the drain.

Yes, flour can be removed with reverse osmosis, but please be sure to check claims and certificates from individual manufacturers for each model. Reverse osmosis can often remove all dissolved minerals that are not suitable for drinking. To compensate, remineralization is an option, but be careful when purchasing such a product to make sure that you are getting good quality. Regardless of whether it is good or bad, how important it is for drinking water, this is an individual choice. Can you recommend a good production producing a remineralization module, and is it possible to add it to your system? Here are some reliable resources that can help you. . All floors had to be replaced.

Does the water drain into the sewer constantly?

Water goes into the sewer as long as the filter system is working, before filling the storage tank. Then the valve blocks the flow of water.

How often do I need to change cartridges?

Pre-treatment cartridges need to be changed every 4-6 months, depending on the quality of the incoming water and the amount of water consumed. The membrane can work from a year to five years. The service life of the membrane depends on the pressure in the pipeline, the quality of the incoming water, the amount of water consumed, and the water temperature. On average, the membrane works for 2-3 years. The post-filter changes once a year.

No system will be 100% proven, but you can consider products that can detect a leak and automatically turn off the water supply. With any plumbing in the house, it is recommended to periodically check the water supply and hoses included in them. Look for small cracks in the hoses, small leaks in the joints, etc. warning signs usually appear before a complete failure. Often this does not come from a water treatment system, but from plumbing connections. . What are the different methods for purifying your own water?

What is the best filtration system product to remove fluoride and contaminated water? 3: What is the durability of these products? Have you heard the recent crisis in Flint Michigan? By the way, the local water area here also turned out to be above the same limits and downplayed the consequences, at the same time assuring me that steps were being taken to rectify without any time frame. I have very heavy water in the new house that we bought, and we need to put a softener. It seemed to me that carbon was impossible. Is this true, and can you suggest a way around this?

What is included in the maintenance of the reverse osmosis system?

Cartridge delivery and replacement. Revision of nodes and connections. Membrane testing can be performed using an electronic device TDS-meter (TDS-metr). Which is designed to determine the quality of the water after the reverse osmosis filter and the total salinity of any water.

What is the value of TDS (total salinity, mg / l) after the system?

About 5-20 mg / l

I am afraid that we do not specialize in residential softeners, but we hope that the above ideas will help. We often change filters, as we currently have a problem when it has a low flow, and changing filters becomes a problem.

- Each well has unique challenges.

- Is there a specific problem you are trying to solve?

- Taste, smell, bacteria, iron, hardness?

- The installation will be very simple since you already have the bar picker installed.

- Thanks for the question - I hope this helps!

At what TDS should the membrane be changed?

When the TDS after the filter exceeds 20% of the source water.

What is the value of TDS in tap water?

Within 150 - 250 mg / l.

How often do you need to maintain osmosis?

2 times per year.

What is the performance of filters with a reverse osmosis system?

50, 75, 100 gallons per day. Depending on the installed membrane. (1 gallon \u003d 3.79 L)

At what pressure does osmosis work?

From 2 to 6 bar.

What to do if the pressure in the water supply is less than the permissible?

With a low pressure of water in the water supply system or with increased consumption of purified water, the system can be supplemented by a pressure-boosting pump.

What to do if the pressure is above the permissible?

If the pressure in the system is higher than permissible or can rise (it happens in new high-rise buildings of 22 floors and above), a pressure reduction gear must be installed.

Why clear water has a milky color.

Typically, this happens when the system is only turned on due to a large number of air bubbles. It does not affect water quality. After parsing 10-20 liters of water, the water becomes transparent.

Is there little water in the storage tank or is it filling up very slowly? Is there no water in the filter?

- The system has just begun to work.

- The storage tank has high air pressure.

- There is little air pressure in the storage tank or it is not there at all.

- Weak water pressure in the water supply.

- Kinks of tubes.

- Filters are dirty or the membrane does not work.

Smell or smack near the water.

- The storage tank is not sufficiently flushed.

- The carbon filter (5-stage cleaning) has exhausted its resource.

- The membrane is dirty.

How long does it take to fill the storage tank?

2 hours on average. Depending on membrane performance, system pressure and water quality.

What is the taste of water purified on a reverse osmosis system?

The water obtained by reverse osmosis has a high degree of purification. In chemical composition, it is close to melt water, which is the most environmentally friendly.

How to determine the cost of a liter of purified water by reverse osmosis?

The undoubted advantage of using reverse osmosis to provide clean drinking water is that it is much cheaper.

Calculation of the cost of a liter of water when cleaning with reverse osmosis

On average, people, according to minimal estimates, consume about two liters of drinking water per day with cooked food, drinks and in pure form. If we consider the volume of water consumption by a family of four people per year, then it will be

2l x 4 people x 365 days \u003d 2920l

The filter life with reverse osmosis system is at least 10 years. In this case, with the price of the equipment $ 300., Depreciation costs per year are $ 30. The cost of consumables consists of:

- the cost of pre-filters (changed twice a year) $ 11 x 2 \u003d $ 22;

- the cost of a post-filter (changes once a year) $ 13;

- the cost of the membrane, based on three years of operation, will be $ 38/3 \u003d $ 12.67

The total cost per year is $ 68.

The cost of one liter of water cleaned with a filter with reverse osmosis system $ 0.023. (68 $ / 2920l).

Reusable osmosis plants (for example, DVS-M series according to TU No. 3697-003-46824383-2004), commercially available from NPK Mediana Filter, are intended for treating water from underground and surface sources by desalting or adjusting the salt composition. They are used to supply water of a given quality to energy and industrial enterprises, and drinking water supply facilities.

NPK "Mediana-filter" presents modern systems of water purification and water treatment:

|

dimensions

Fig. 5.18. Hydraulic diagram of reverse osmosis unit DVS-M / 150-4 Technical characteristics of the reverse osmosis water desalination plant:

The DVS-M / 150-4 reverse osmosis unit includes: a microfiltration unit, a membrane unit, a control unit for the operation of the water treatment plant and water quality control, a chemical washing and regeneration unit, instrumentation, and shut-off and control valves (Fig. 5.18). Pre-prepared water that meets the water requirements for reverse osmosis plants is fed to a pre-treatment unit consisting of F1 filters with a rating of 20 μm and F2 with a rating of 5 μm and removing suspended insoluble particles larger than 5 μm from the water. The degree of contamination of the filter elements is determined by the pressure drop on the pressure gauges P1 and P2. Next, the water enters the boost pump H1. At a pressure of about 10–12 atm or 14–16 atm (depending on the type of installed membranes) created by the H1 pump, water passes through a reverse osmosis membrane block, where the flow of source water into the filtrate and concentrate is separated. This design uses from 1 to 4 membrane elements of type BW 30 of size 4040, housed in individual membrane cases made of stainless steel. Membrane modules are connected in parallel along the filtrate and sequentially on the concentrate - i.e. concentrate from the first module enters the second (Fig. 5.18), where pure water is additionally extracted from it, then to the third and fourth. This makes it possible to significantly reduce the consumption of prepared source water and the volume of discharged concentrate. So, at the same water pressure at the inlet to the membrane unit, the concentrate stream with respect to the filtrate stream will be approximately: The concentrate is partially directed to the pump inlet through a recirculation loop, and the rest of it is discharged into a drain (sewage). Recycling of the concentrate, the flow rate of which is regulated by the Dr2 throttle, allows to further reduce the need for source water with a slight deterioration in the quality of the purified water. In this case, the flow rate of the concentrate from the filtrate volume is: The operating mode is set by the throttle concentrate Dr1, which controls the working pressure on the reverse osmosis membrane unit. It is very important to ensure the maximum duration of operation of reverse osmosis elements is the presence of the so-called phase of hydraulic washing of the membrane block, carried out before the start of clean water production, and periodically during the operating mode of cleaning, with an interval of 1 hour. Quick hydraulic washing is carried out by opening valve K2, parallel to the throttle Dr1. As a result of this, the flow of water through the membrane block in the concentrate chain increases sharply and the working pressure on the reverse osmosis membranes drops. The duration of hydraulic flushing is 10-50 seconds. Filtrate, i.e. demineralized water enters the storage tank. Its quality is controlled by the readings of the conductivity sensor Q E1. If the quality does not match the set, the controller turns on the flushing mode of reverse osmosis membranes. If necessary, an extraordinary hydraulic flushing can be carried out manually by fully opening the throttle concentrate Др1. The control unit is implemented on an electronic programmable controller that allows you to automate the process of obtaining purified water. The unit includes built-in conductometers, pressure sensors, dry running, temperature and executive solenoid valves are connected to it. The controller monitor displays the values \u200b\u200bof conductivity, temperature, status of pumps, valves, etc. Also, according to messages in the running line (in automatic operation mode), one can judge the phase of the installation and the presence of emergency situations. During operation, reverse osmosis membranes are clogged with deposits of hardness salts, coagulated colloids and organic compounds, which entails a decrease in productivity and a deterioration in the quality of the resulting filtrate. To eliminate these negative phenomena, a chemical washing of reverse osmosis membranes is periodically performed. To carry it out in all industrial plants, they are equipped with a stationary flushing module. It contains a container, a pump, a heater, a microfilter and a system of stopcocks, a set of additional hoses for connecting the washing unit to the membrane unit (Fig. 5.19–5.21). Fig. 5.19. Simplified diagram of a chemical washing unit for reverse osmosis plants Different types of acid solutions are used (all of them are used at a temperature of 40–45 ° С):

Fig. 5.20. Chemical washing unit for reverse osmosis membrane elements for installations of the DVS-M / 150-8-6- series (18) An alkaline solution containing inorganic complexing agents is used to remove silt, biological and organic contaminants from the surface of reverse osmosis membranes. pH of the working solution is 12.2–12.5. Washing is considered complete when the pH exceeds 10.5. An alkaline solution with an initial pH of 11.0–11.25 is used to remove contaminants, including silicon compounds. Washing is considered complete when the pH of the washing solution is stabilized, but will exceed 10. Fig. 5.21. As a rule, the cycle of treatment with a detergent composition consists of several operations, including: heating the solution, circulating washing with the reagent solution for 20–30 min, holding reverse osmosis membrane elements in the washing solution from 20 min to several hours, and additional recycling for 15–20 min and washing the water treatment plant from the remains of the solution with purified water. Such a cycle is carried out for each of the chemical agents used. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||