Industrial reverse osmosis and membrane desalination ZauberROS series. Reverse osmosis. Theory and practice of application.

Reverse osmosis is the process of passing treated water through a membrane under the action of an applied pressure in excess of the osmotic.

The cleaning technology at the installation consists in filtering the liquid through semipermeable membranes that pass the solvent (water) but retain dissolved substances (hydrated salt ions and molecules of organic compounds). Reverse osmosis is a baromembrane method whose driving force is pressure (exceeding the osmotic pressure).

To mitigate and desalinate drinking and commercial water depleted in manganese and iron, it is controlled by the flow of water. Individual or dual softeners, osmotic devices, diaphragms, a high-performance high-pressure pump with a flange motor, a needle valve control unit, two solenoid valves, a flow meter, a 5 micron filter and two pressure gauges for filter and pump pressure. An electronic microprocessor device for monitoring osmosis softening equipment depending on the quantity, monitoring the tank level, the automatic run-off program at rest, a digital measuring device, a contact for measuring limit values, level control, and control in accordance with limit values.

In water treatment systems, the most widely used reverse osmosis roll elements. The roll elements consist of two semi-impermeable membranes and a water-supplying catchment layer of flexible tape elements wound around a central perforated catchment pipe (Fig. 1). Source water enters the roll module, and two flows are discharged - purified / demineralized water, which is called permeate, and concentrated water with impurities, called concentrate.

All components are located in a stainless steel frame and housing. The storage tank and pressure pump are already integrated.

Reverse osmosis to remove softening of drinking and service water. The device is located in a stainless steel frame. High pressure pump, osmosis module in a stainless steel pressure vessel, control unit with solenoid valves, permeate and concentrate flowmeter, pressure gauges, protection against falling water pressure, 5 filter. Electronic device with digital indicator, limit switch, operating value indicator, pressure and level control, automatic rinse program after each sample.

Figure 1. The structure of the reverse osmosis roll element

Rolled elements are divided: by scope of application (purification of tap, brackish or sea water), by productivity.

Advantages of reverse osmosis over ion exchange:

- high level of automation and reliability;

- low operating costs;

- ease of maintenance;

- minimum space requirement for installation;

- lack of a reagent farm.

The composition of the installation IT-M (O)

The installation includes:

Textbooks claim that milk is a source of calcium for our teeth and bones. Our test showed that this is indeed so. Each liter of milk tested contains enough calcium to cover the recommended dose for one person for a day and a half. All milk also had sufficient protein and vitamin content. The laboratory did not detect heavy metals, pesticide residues or dangerous bacteria in any of the milk purchased.

Reverse osmosis is a method of filtering water under pressure through a special membrane that passes only pure water molecules. The dirty water and the dirty ingredients in it merge into the drain and leave your kitchen forever. In addition, reverse osmosis removes bacteria and viruses, and also reduces water hardness. So much water purification cannot be done quickly. Since you always have access to clean water in any quantity, reverse osmosis is always equipped with a reservoir for collecting clean water.

- pre-cleaning unit;

- reagent dosing unit;

- membrane module blocks;

- flushing unit

- instrumentation and automation systems.

Installation Description

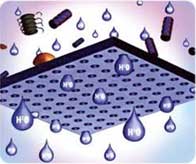

In fig. 2 shows the installation with the designations of its constituent blocks.

To prevent suspended particles from entering the reverse osmosis membranes, the source water is first supplied to the pre-treatment unit (1). Depending on the quality of the water, after the pre-treatment unit, a reagent (sulfuric acid and / or inhibitor) may be supplied in proportion to the flow rate of the source water; to prevent the formation of sediment on the membranes. Next, a high pressure pump with the required pressure and flow rate is supplied to the membrane modules (2). Water on reverse osmosis modules is divided into two streams: concentrate (15-40%) and permeate (demineralized water) (85-60%).

Due to the increased reverse osmosis filtration rate, you get 1 liter of pure water in five minutes, twice as fast as regular reverse osmosis. Thanks to an efficient automatic drainage system, twice as much water is used to flush the membrane than with conventional reverse osmosis. You do not need to worry about how much water is left in the tank.

And again you will save time and money!

You do not need to install a pump to increase pressure. For ordinary reverse osmosis, at least 3.5 atm is required. Changing the inserts is incredibly simple and takes only a few minutes: you do not need to parse anything, just click the button and add a new insert.

The clarified water after clarification installation (ultrafiltration or clarifier with mechanical filters) or permeate of the first stage reverse osmosis installation can serve as the source water for the reverse osmosis installation.

During operation of the installation, its performance gradually decreases. This is due to contamination (inorganic or organic) that has formed on the surface of the membrane. It is possible to remove contaminants and restore the performance of membrane blocks during preventive regenerative leaching (1-2 times a year, depending on the quality of the water). Flushing is carried out using the flushing unit (3).

What can remove this filter from water?

The system is back to work!

General explanation: cold water flows from the water inlet to the water purifier inlet, passes through the water pre-treatment unit, then flows through the automatic valve to the reverse osmosis membrane. Pure water enters the tank. Finally, when the faucet opens, clean water passes through the control stage and gets to you.

The water purification step is a polypropylene liner that captures particles larger than 20 microns. It provides preliminary purification of drinking water from sludge and dissolved impurities, which means that it removes sand, mechanical additives and rust spots.

Figure 2. Installing reverse osmosis:

1 - preliminary cleaning unit, 2 - membrane module block, 3 - washing unit

The principle of equipment selection

Specialists of Ion Exchange Technologies JSC are developing a reverse osmosis unit for specific technical needs of the customer.

The filter material has high hydrophilicity with a labyrinthine pore structure, which allows you to effectively remove insoluble impurities with a particle size of more than 5 microns, including iron hydroxide. Microcrystalline silver is used as a bactericidal element. The degree of purification is a reverse osmosis membrane, which removes water from organic and inorganic substances, salts, bacteria, viruses, cysts. The fuselage in which the membrane is located is equipped with two exits: east of pure water and an outlet of drainage water.

Drainage water then flows into the sewer through a current limiter. The next stage is the supply of clean water to the tank for water and water. The power of the reverse osmotic system is 7.8 liters per hour. After cleaning, automatic water enters the water tank to always have the required amount of clean water. When the filling tank is full, the automatic valve closes the water inlet to the reverse osmosis membrane.

Standardly, the following work steps are carried out before the installation is delivered:

- technological calculation of the installation

- pilot field tests on real water of the customer (if necessary)

- selection of the optimal technical solution for a particular water (selection of the type of reverse osmosis element, determination of the real auxiliary needs of the installation, etc.)

- development of design documentation for the installation, taking into account the required performance, the results of pilot tests, the availability of specific reagents, etc.

- designing the required installation, taking into account the availability of free space for construction and other features of the site.

The range of reverse osmosis plants being developed is from 50 to 1000 m 3 / h.

How often do inserts change and how long does the plant work?

Reverse osmosis consists of 3 filter modules, 1 osmotic membrane, 1 tank, 1 tap, sets of hoses for connection. Inserts located in degrees change every 1 year. The diaphragm that is in the class changes once every two years.

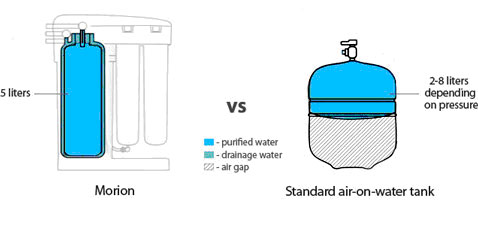

What is Aquaphor Morion reverse osmosis different from others?

Coconut carbon block. And thanks to this, the life of the insert is increased by 3 times. The dynamic fixation of silver in Aqualen. Active silver, which is distributed through the patented Aqualen fiber. In conventional filters, silver is on carbon, which does not have a stable surface, and therefore it is washed in filtered water for a short time. Since silver is a heavy metal, it becomes a harmful substance in large quantities.

Standard installations are developed for:

- turbidity content - up to 1NTU (0.5 mg / l);

- chlorine content - up to 0.1 mg / l;

- temperature range - 5-45 ° С;

- sDI value is up to 5.

Reverse Osmosis Pilot Tests

In most cases, pilot tests for the development of a reverse osmosis system are not required. By calculation, it is almost always possible to solve problems with the removal of calcium, magnesium, alkalinity, sodium, silicon, nitrates, fluorides, sulfates and chlorides.

Thanks to the new design and design, the sorbent volume in the insert increases up to 10%, which affects the service life and quality of cleaning. Thanks to new dimensions and sophisticated technology, the filter can be placed anywhere in the kitchen. The module block is mounted on the original patented collector design using the new block module concept, which ensures perfect compactness.

No effort or special tools are needed to remove the insert. Just press the button and turn the module slightly by hand. When inserting, simply insert the module into the collector and twist it to snap it into place. When replacing the module, you replace not only the filter material, but also update the body of the water purifier. This prevents the spread of bacteria during prolonged use of the filter.

However, sometimes it is necessary to remove substances from the water (almost all the rest that are not included in the list above), for which there is no standard calculation procedure. In addition, there are cases when it is necessary to remove the above substances under non-standard conditions (for example, a very high or low pH value) or it is required to conduct life tests of the installation under conditions of processing solutions in it in a nonequilibrium state. In these cases, pilot tests are required.

The reservoir for water and water is a source of clean water. This collection tank has a built-in diaphragm that divides it into two parts: feed and control. In the spare part there is completely clean drinking water, in the tap water, which is already equipped with carbon filters. During the collection of clean water, tap water is supplied to the drainage and does not create a counterflow for the influx of clean water. As soon as the filling tank is full, the automatic valve closes access to water for the water purifier.

![]()

Morion takes up 50% less space than traditional osmotic cleaners, thanks to its integrated stack. It is compact enough to fit under the sink. Therefore, there is no excuse that you should drink bad water because you live in a small or old house. You deserve the best.

JSC “Ion-exchange Technologies” has its own pilot reverse osmosis unit, which, among other things, can be an element of a complete technological scheme, including, for example, reagent softening, clarification by ultrafiltration or mechanical filters, etc.

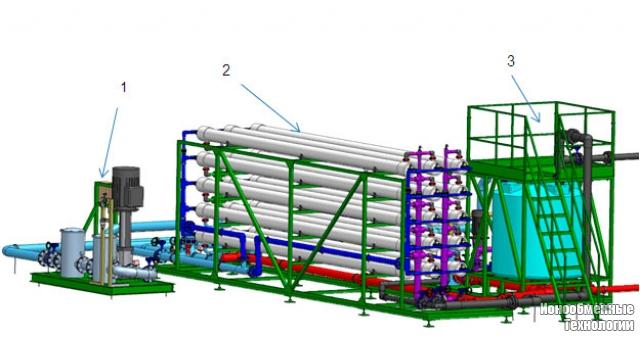

The pilot installation (see Fig. 4) is designed for a maximum capacity of 5m 3 / h.

This allows you to work efficiently with a Morion water pressure of less than 2 without using an overpressure pump. The magazine can also be filled with purified water in just one hour and at the lowest working pressure.

The main department, located in Nuremberg, has more than 30 offices throughout Germany and abroad.

The company carefully selects the most durable products, which will then undergo numerous tests and analyzes conducted only by the best accredited European laboratories by highly qualified specialists. Membrane systems are used to treat seawater, brackish water, and drinking and distilled water.

The installation includes, among other things, three stages of desalination by concentrate. The last stage is designed to work on water with a salinity of more than 20 g / l (almost on sea water).

All diaphragm systems require high pressure diaphragms, high pressure pumps, an integrated regulator and the necessary pre-cleaning. Membrane filtration is a physical process that uses a semi-permeable membrane to separate and remove soluble particles, organic colloids, viruses and bacteria from water.

Water from sources is purified before penetration into the membrane. This saves a large amount of acids and other aggressive substances necessary for the regeneration of the resin. Which will not emit any pollutants, bacteria or other harmful substances. It also works without a pump and holds up to 5 liters of clean water in a special tray. If you want to pack clean water, you can also use a separate tap that has reverse osmosis. Super compact design, clear water, without pump and tap, that's all that reverse osmosis offers!

Fig. 4. The appearance and layout of the pilot installation of reverse osmosis

The composition of the pilot installation:

- source water tank;

- feed water pump;

- fine filters;

- reagent dosing unit;

- three stages of membrane module blocks;

- intermediate tanks and pressure boosting pumps between desalination stages;

- permeate tank;

- flushing unit

- Instrumentation (pressure gauges, pressure sensors, flow sensors, temperature, pH, level sensors),

- electrical control cabinets with controller and monitor

One of the most modern methods of purifying water from impurities is reverse osmosis. This technology is carried out using a reverse osmosis membrane. Water during reverse osmosis is passed through a membrane, the pores of which pass water, but do not pass the impurities dissolved in it.

The reverse osmosis system allows you to get water of a very high degree of purification (close to distilled). Reverse osmosis filters produce the highest quality (complete) water purification.

Such harmful substances as magnesium, mercury, nitrates, nitrites, strontium, arsenic, lead, sulfates, iron, chlorine, as well as many (but not all), bacteria and viruses are removed from the water.

Unfortunately, reverse osmosis removes from the water more than 20 useful substances: calcium, magnesium, sodium, fluorine salts, etc., which are extremely necessary for human health (at least 500 mg of useful salts should be in drinking water) . Therefore, water purified by reverse osmosis is "dead" - purified, but not good for human health. Moreover, such water is aggressive and easily flushes vital minerals out of the human body, leading to strokes and heart attacks.

Reverse osmosis is implemented as follows. Semi-permeable osmotic membrane prevents the alignment of concentrations of substances on opposite sides. The flow of water is forced through the membrane, which rejects impurities, maintaining their high concentration on the side from which the water flows.

The filter, operating on the principle of reverse osmosis, is designed quite simply: the main element that allows you to get high-purity water is a thin-film membrane. The reverse osmosis membrane is a kind of grid, the cell size of which is comparable to the size of a water molecule. Due to this membrane structure, practically all dissolved components, as well as salts of heavy metals, organic impurities and bacteria are removed from the water. During operation, filtered salts and various impurities gradually accumulate in front of the membrane, due to which it can become clogged and stop working. In order to prevent this from happening, prefilters are installed in front of the membrane - several stages of preliminary cleaning. Among them, there is always a stage of cleaning from mechanical impurities, trapping sand and insoluble impurities. For the continuous discharge of these "wastes" along the membrane, a forced flow of water is created, washing away concentrated contaminants into the drainage.

It is worth noting that reverse osmosis is borrowed from wildlife. Osmotic regulation underlies the metabolism of all organisms. The cell walls of plants, animals and humans are a natural reverse osmosis membrane, which is partially permeable, because it freely passes water molecules, but not molecules of other substances. The filtering ability of a natural membrane is unique, it separates substances from water at the molecular level, and this is what allows any living organism to exist.

Thanks to it, the necessary substances enter into every living cell and unnecessary ones are removed. The principle of reverse osmosis was originally applied to desalinate sea water.

However, the cleaning method - reverse osmosis has several disadvantages.

Firstly, although reverse osmosis plants are not very expensive at first glance, the operating costs for their operation are about an order of magnitude higher than the operating costs of other methods of water treatment (aeration, ion exchange, ozonation, etc.). The common phrase "put like a drug addict on a needle" perfectly reflects the position of the buyer of the reverse osmosis (membrane) installation. If the average cost of 1 cubic meter of Moscow tap water is 30 rubles / cubic meter, then the cost of 1 cubic meter of water purified at a reverse osmosis installation is about 300 rubles cubic meter.

Such a significant amount of operating costs is also determined by the fact that for the operation of the reverse osmosis installation, round-the-clock operation of very powerful pumps that pump water through very thin membranes is required. In addition, the more polluted the water at the inlet to the membrane installation, the more often it is necessary to change expensive membranes - the more significantly the operating costs increase.

Secondly, reverse osmosis is one of the lowest performing water treatment methods. Membranes let water through slowly and have poor performance. Therefore, in some cases, this method requires the installation of an impressive and expensive storage tank made of stainless steel.

Thirdly, the water in front of the reverse osmosis membrane must necessarily undergo a thorough preliminary treatment at any installation with traditional water treatment technology. In essence, this means an increase in the initial cost of the membrane installation.

Fifth, the reverse osmosis water treatment technology is essentially Samoyed: when the reverse osmosis system is operating, up to 75% of the water being purified is discharged into the drainage (whereas with traditional methods of water treatment, it is only 5%). At the end, the user receives only 25-30% of water. True, the water is very well purified. But not useful, but harmful to human health.

Sixth, the reverse osmosis method is invariably associated with the use of modern membranes. In order to increase the efficiency of reverse osmosis filters, • nanocrystals and special modifiers are often used. To the safety of such substances, disputes in the scientific world do not stop to this day.

Seventhly, membrane separation methods are not able to capture organically volatile substances whose molecular size is less than the diameter of water molecules. That is why membrane filters cannot retain particles of insecticides and herbicides. On the other hand, reverse osmosis membranes are easily clogged with barium sulfate, strontium, calcium carbonate, silicon dioxide and ferro compounds, and require very frequent replacement.