Portal about the pumps. Rotary pumps: vane, vacuum, with wet rotor. Rotary pumps.

Rotary pump – This is a volumetric pump in which liquid is displaced from displaced working chambers as a result of rotational or rotational and reciprocating movement of working bodies - displacers.

The working chamber of a rotary pump is limited to the surfaces of the constituent elements of the pump: a stator, a rotor, and a displacer (one or several).

Air enters the fan chamber through a channel located in the center of the blower, where the air moves in the radial direction, and the centrifugal force is accelerated and compressed. Compressed air is radially discharged through an opening at the edge of the fan chamber. If several compression steps are included, the process is repeated and the overpressure value increases. Low thrill radial compressors achieve high air transport. The wheel does not touch the wall of the compression chamber, therefore, lubrication is not required, the compressor compartment does not contain oil.

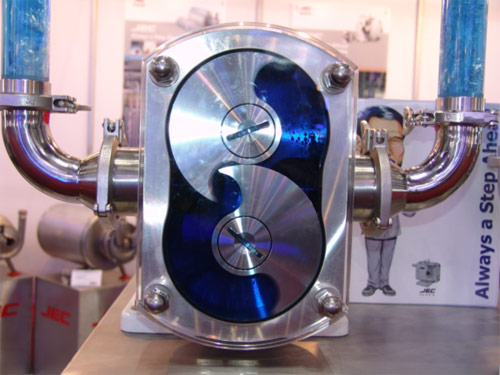

By the nature of the movement of the working bodies (displacers), rotary pumps are rotary-rotary and rotary-translational (classification scheme according to GOST 17398-72 see in Fig. 2).

Rotary rotary pumps

In rotary rotary pumps, displacers perform only rotational motion. These include gear (gear, rotary) and screw pumps. In gear pumps, working chambers with liquid move in a plane perpendicular to the axis of rotation of the rotor, in screw pumps - along the axis of rotation of the rotor.

Intelligent way to transfer air. So far, hints of a pump outlet have had certain characteristics. This system allows the user to change specific indices or maintain these indices at constant levels. Air supply adjustment is performed automatically according to user requirements. At the same time, a specific mode of operation is realized, which, thanks to the pressure difference and the transported air flow, provides maximum flexibility in all areas where it can be used.

This innovation can be represented as follows: the user has the amount of air needed to complete the tasks - no more or less -. Automatic satisfaction of requirements opens up new perspectives, such as: - extended scope, - optimal and high performance - variable system configuration.

Rotary progressive pumps

In rotary-progressive pumps, displacers perform both rotational and reciprocal movements. These include vane (vane, figure-vane) and rotary piston pumps (radial, axial). In rotary piston displacers are usually made in the form of pistons or plungers, which are located radially or axially with respect to the axis of rotation of the rotor. All rotary-progressive pumps can be made both in the form of adjustable machines, that is, with a variable displacement, and not adjustable. All rotary rotary pumps are unregulated.

Heat, noise and environmental conditions have the same impact on working conditions as the cost of maintenance and energy consumption in the enterprise. For example, if the printing house has more vacuum pumps and individual blowers, then the factors causing environmental changes multiply.

There are several problems at the same time. The heat removed from the individual pumps significantly increases the temperature in the room and can overload the air conditioning devices. The noise level generated by pumps and blowers combined with room noise can mean high mental effort for employees.

Fig. 2. Pump classification

Due to the fact that rotary pumps move the working chambers with liquid from the suction cavity to the discharge cavity, these pumps differ from piston (and plunger) pumps in the absence of suction and pressure valves. These and other design features of rotary pumps determine their common properties, which are also different from the properties of piston pumps, namely: reversibility, that is, the ability to work as hydraulic motors (hydraulic motors) when the fluid is supplied to them under pressure; higher speed (up to 3000 - 5000 rpm) and greater uniformity of feed than piston pumps; the ability to work only on clean, non-aggressive fluids with lubricating properties (the use of rotary pumps for water supply is excluded).

To achieve maximum load, it is often necessary to use new capacities. But they do not work economically. In such cases, if one of the devices fails on the entire line, it is “quiet”. High energy and operating costs. Separate maintenance of each device takes a lot of time. Failure to use all available capacity can reasonably raise your electricity bill.

A central brokerage system can be the solution to these problems. A clean and unpolluted workplace increases the level of comfort for employees, and the finance department can save. The centralized system is located in a separate and enclosed room. Vacuum pumps or blowers are connected to the main supply pipe. in the production hall you can mount branches or where necessary. The air requirements for each machine can be adjusted using a control valve. Therefore, the machines can operate on the basis of their own air requirements, which are practically independent of the boiler self-regulation system.

- 532 views

Rotary pumps are a volumetric type technique that differs from dynamic pressure equipment (centrifugal, vortex, etc.) in the way that liquids are transported. For devices of this category of technology, two types of movement are characteristic: rotational or rotational with reciprocating action.

Dedicated to Andrew Livingston

Why not design a pump that uses only the spare parts that may be available. Like the other documents on this website, it is based on the principle that the community grows stronger by solving the problems themselves, instead of waiting for charity on the street.

Technical and technical aspects are intended to illustrate this principle. The wire pump, quite popular today in Central America, has several advantages and disadvantages. Our discussion focuses on illustrating how a solution to this problem can help build the capacity of a limited-income community. It is intended for community mobilizers, even if it may seem funny to an engineer or technician.

All sorts of design options are governed by GOST 17398-72.

1 Rotary pumps: classification and principle of operation

So, rotary pumps are divided into two main large groups:

In turn, rotary-rotational can be:

- gear (with internal or external gear engagement);

- screw (gear: single screw with external engagement of screws).

And rotary-translational are divided into:

The principle of the wire pump is relatively simple. It consists of a solid rope of rope. He wraps a bicycle wheel at the top of the well. The bracket drains into the well, and then rises up to the top of the plastic pipe. The bicycle wheel can be manually operated so that the rope goes down the pipe and then rises again inside the pipe. Using a welding machine and a saw, the bicycle frame can be changed to support the wheel, and the pedals can be turned into a crank. When the rope rises inside the pipe, the valves push water from the bottom of the fountain up.

- gate valves (the so-called rotary or vane-rotor vacuum pumps);

- rotary piston or plunger devices (axial and radial).

In addition, by the principle of the structure of the pump rotor itself, this volumetric pressure technique is classified as:

- wet rotor pump;

- dry rotor pump.

1.1 Principles of operation of a rotary pump

The main distinguishing feature of rotor technology was the fact that its design completely lacks valves. Rotary vane pumps operate on the principle of interaction of fluid with the working body in moving chambers, which are alternately connected to the suction and discharge cavities.

All components of wireline pumps are commonly found in any small town: rope, tire waste, bicycle frame and wheel, and plastic tubes. None of this is expensive. The wire pump has been used for years and years, even decades, but over the past few years has become extremely popular and widely used in Nicaragua.

Water pumping technology is not a complicated science. For more than half a century, helpless projects in Europe and North America or multilateral institutions have assisted in providing drinking water to rural communities in Africa, Asia, South America and other low-income countries.

The rotary pump works because the volume of the working chamber is constantly changing. First, the liquid fills the chamber, and then is pushed out of it into the discharge region through the nozzle. In this case, the working chamber itself looks like a temporarily created closed volume, which is limited to the details of the device itself inside the case.

Hand pump technology has been developed for use in families in Europe and North America and does not appear to be suitable for public services serving 500 or more people, regardless of what technical improvements have been undertaken or how much training has been given. This technology turned out to be unsuccessful, as its inventors and those who tried to improve it get rid of some important questions about the values, behavior and organization of people who need water.

Or is it the reason that manufacturers profit from the sale of spare parts and are not interested in creating pumps that are kept? Once the authorities have chosen a certain type of hand pump, it is economically logical to take steps to ensure that all pumps installed in the respective region are of the same type so that the same model of exchange parts can be used. Thus, manufacturers have a market that depends on such spare parts.

The change in the volume of the working chamber in the gear equipment occurs due to the rotation of the gears in a screw installation by rotating the screw around its axis. In rotary vane pumps due to the fact that the rotor of a centrifugal pump with longitudinal slots, where the plates (gates) are inserted, rotate along an axis that does not coincide with the axis of the housing.

An important issue is the production of cheap spare parts for rural communities. Cheaper, but less resident, spare parts can be a smaller problem, as local suppliers will be willing to keep them in stock. Private enterprises can handle the situation.

Large and rarely replaced parts are not preferred traders because they cost money for storage and are not profitable. The market is too small. He is trying to get government subsidies for these spare parts, or even the possibility of storing them for free.

Moreover, depending on the structure of the rotor and the number of gates, the vane pump according to the principle of operation can be single, double, triple, etc. And so that the chamber of the vacuum-vane rotary pump is closed, a sufficiently tight fit of the plates to the housing must be ensured.

The rotary plunger pump (piston type) due to the lack of valves, and, as a consequence, the ability to perform reverse translational movements, can be used as hydraulic motors.

The larger the sale, the more efficient the sale of spare parts. Economists believe that a way to make a profitable supply of spare parts is that they can be used for other purposes. Valves and bearings, for example, which are used for vehicle engines will be available in stock in the market much more than parts used only for hand pumps. This market is very low. There are some efforts to develop new hand pumps that can use replacement parts already available in other markets.

1.2 Principle of operation of a rotary vane compressor (video)

1.3 Advantages and disadvantages

Among the disadvantages of devices of this type, there are only two main ones:

- increased demand for pumped fluids. They must be non-abrasive and non-aggressive;

- the complexity of the design can lead to a decrease in reliability and increase costs for production and maintenance.

But among the advantages, one can undoubtedly distinguish such characteristics as ensuring the self-priming process without the use of auxiliary devices and low-speed rotation, the ability to reverse the fluid flow and the adaptive capabilities of the discs, high levels of efficiency and suction heights, low noise and vibration levels, a constant average level of performance and ease of execution of mechanisms.

A wider market is more productive and easier to maintain. The rope pump obviously has all the details, the whole assembly, the available markets are widespread in the areas that interest us. Some of them, such as bicycles and damaged worn tire numbers can even be found in landfills. Collecting them can be a lucrative business for these recycled materials.

Many people in the government, body or person responsible for the examination are invested in maintaining the current situation. Hand pump technology is a profitable business for industrial enterprises in Europe and India, or in countries where this area is subsidized.

In addition, the rotary pump is able to work with liquids of various viscosity and temperature indicators, as well as with various inclusions of gas or air, can work in dry mode for some time and have the ability to dispense independently.

Although raw materials for hand pumps are quite common, manufacturers add significant value when used in pump manufacturing, which makes a significant profit. The possibility that the pump can be made entirely from local materials by artisans who can use these materials and other products is causing fear to the pump manufacturer and their supporters.

They will also be forced to provide gifts from government agencies to enact laws and regulations that favor the use of hand pumps to the detriment of local alternative solutions. Keeping things in existence perpetuates the status of poverty and dependence.

Various modifications of pressure equipment of rotary type can withstand pressure from 8 to 12 bar. And some types up to 20 bar. And, among other things, the equipment is compact in design and size, easy to install and maintain.

1.4 Series and specifications

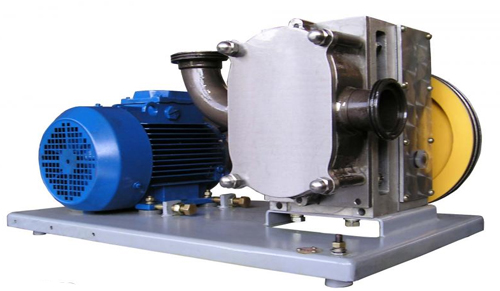

Rotary devices are made in three modifications, which are represented by different serial types of models: M, D, N, T.

In the training module on poverty reduction, one of the five significant poverty factors is dishonesty. When a public servant puts money in his pocket for investment or development, he is dishonest. This is a contributing factor to poverty alleviation. The effect of this is multiplied. Money intended for the development of investment funds; they will contribute to future growth in real incomes. When used by public servants for personal use, they transform from investment to consumption.

This means that, for example, one hundred monetary units of such a development will cost as much as six or seven hundred monetary units in the future development of the welfare of the community. These six or seven hundred units of money are stolen by the community, although corrupt officials simply take a cent for personal use. Even this money of hundreds of units will be lost for the local economy if it is transferred to a bank account abroad - as, for example, in Switzerland.

Type M Series - These are models with one hollow impeller, which can work with liquids of medium and high viscosity. This technique is also not afraid of the presence of solid particles and impurities in the composition of the pumped material.

The equipment can withstand pressure under pressure from 8 to 20 bar, with a speed of up to 100 cubic meters per hour, pr rotation speed of up to 500 rpm. It operates in the temperature range from -20 to +280 ° C.

In the water management sector, the use of wells offers several opportunities for such a diversion of destination money. When a company wants to drill a well or install a hand pump, it will require a significant amount to complete the installation. If the village is isolated, with people ignorant and afraid of the authorities, if you do not control the project, a company that can earn a lot of money without working in reality is just what he did.

The company will provide some of this money to government officials involved to avoid reporting crime. When a well is drilled mechanically and a hand pump is imported or produced in the capital, it is relatively easy to divert investment funds.

Types of flange connections used: UNI PN10, ANSI 150, DIN PN 16. In addition, this type of apparatus has a lot of various types of seals: stuffed and cartridge, mechanical and radial.

Type SeriesD thanks to the presence of two impellers, it is suitable for work in pipelines, valves and fittings. There are two impellers and a high flow rate. Since both wheels work in turn, a constant fluid flow is created and vibration levels are minimized.

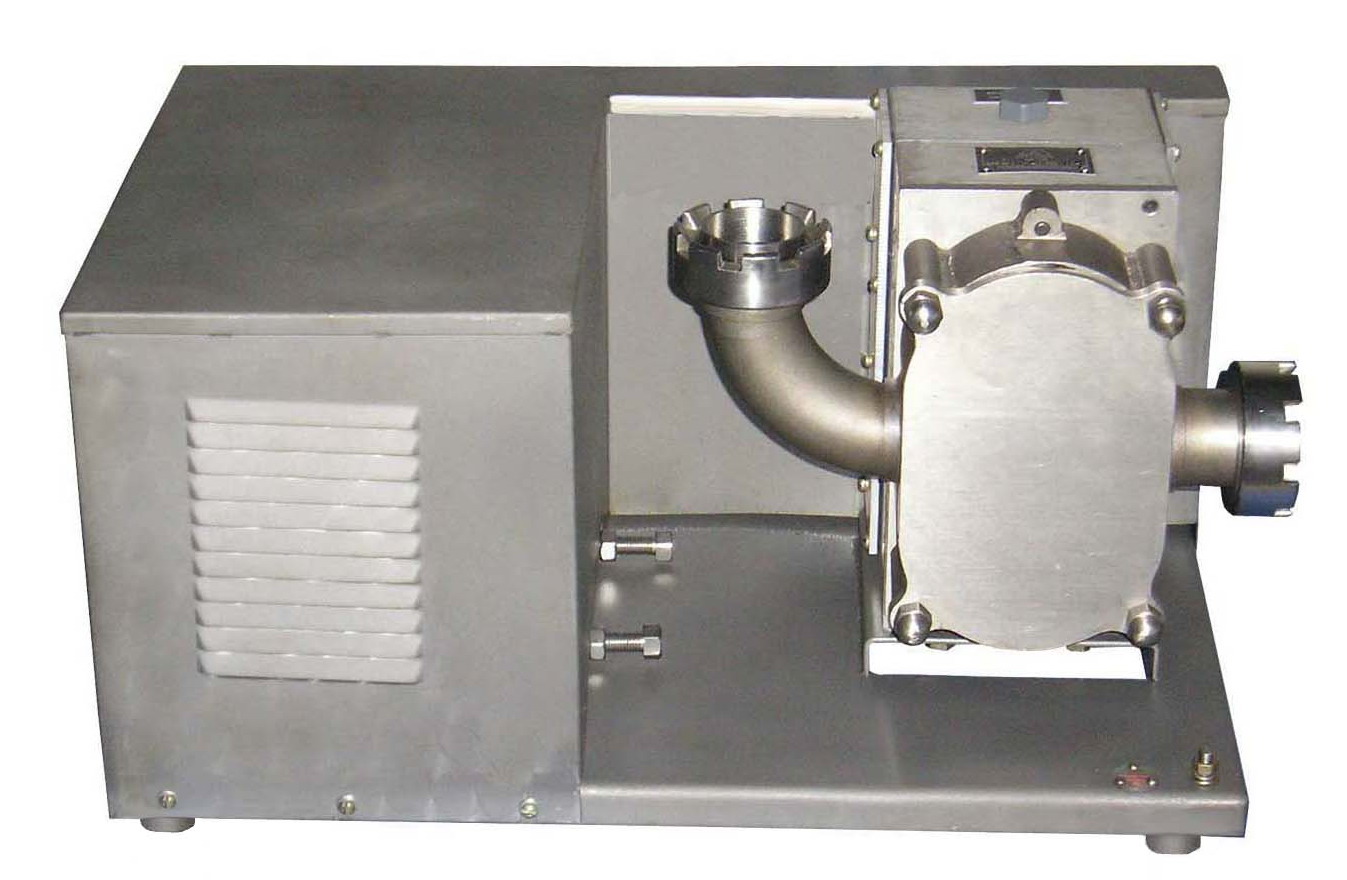

SeriesN it is completed with one or two impellers and support of portable type. They are used for working with liquids of high degrees of viscosity and perfectly cope with the pumping of substances with a small amount of foreign impurities. At the same time, they can provide a flow rate of up to 90 cubic meters per hour and an extremely low threshold ripple.

RA Series - Rotary Vane Vacuum Pumps

T Series it can work with a pressure of up to 4 bar at a flow rate of up to 3 cubic meters per hour at a rotation speed of 950 revolutions per minute. Liquid temperature can be from 0 to +100 ° C. Moreover, it has a greater pulsation than the previous series, but the T series copes well with pumping aggressive liquids and has a good ability to dispense substances that enter the apparatus.

2 Applications

In the petrochemical industry A vacuum pump is used for pumping light and heavy hydrocarbons, lubricating oils, bitumen and tar, benzene and toluene, gasoline and phenol, diesel and petroleum fuels, crude oil, process fluids and petrochemical products, as well as for any kind of oil.

In the chemical industry this pressure apparatus can work with acids and solvents, lubricating oils and additives, wax, glycerin, latex and soap solutions, alkaline liquids and rubber, liquid sulfur and caustic soda, starches, plasticizers and drilling fluids, fibrous polymers and resins.

In the marine industry and shipbuilding they are used for pumping tanker and bilge liquids, oil and diesel fuel, waste oils and wastewater.

In the pulp and paper industry they pump acidic and caustic waters, isocyanates and drilling fluids, cellulose and starches, fiber and adhesive suspensions, paints and inks, enamels, pigments and lime.

In the food and pharmaceutical industries they are used for vegetable and animal oils, fruit juices, pastes and jams, syrups and molasses, animal fats, lecithin and cream, alcohol, chocolate, caramel and fudge, sauces and dough, dairy products and thickeners.

In public utilities Wet and dry rotor circulation pumps are widely used. At the same time, pumps with a wet rotor maintain the necessary pressure in heating systems and do not need lubrication and cooling. Such a water pump is independently lubricated and cooled by the fluid circulating in the system.

Dry rotor pumps are designed to operate without direct contact with the fluid. They are much more noisy in comparison with wet rotary devices, and work poorly with liquids in which various impurities are present.

You can find out more about what a manual rotary and oil-free vacuum pump is, what is the difference between a manual pump for barrels and a vacuum barrel pump in other articles of our site.