Pump for a well. Power consumption. Choosing a pump for a well

If a well can be used without a pump, then a well cannot be dispensed with while operating a well. But well bore - discord. And the quite logical question arises, but how to choose a pump for a well? This is due to the huge assortment of this type of product on store shelves. If the buyer does not have special knowledge, then this is a rather complicated matter, since it is the pump that will ensure uninterrupted water supply to the household.

Well Parameters

Before you go to the store or make an order on the Internet, you must accurately determine the following parameters in order to correctly calculate the pump for the well:

- well depth (these data are entered in its passport, which is handed to the owner after completion of work);

- water quality in the well (the amount of impurities per 1 liter of water, data can be obtained in the profile laboratory);

- well debit - the volume of water pumped per hour of work. (this parameter is necessary to select the pump power - it should not exceed the debit);

- the distance from the water level in the well to the soil surface (measured independently using a weight on a rope);

- the distance from the point of water spill to the surface of the earth (this parameter is necessary to select the pump by power);

- the diameter of the well pipe (these data are entered in the passport of the well, which is given to the hands of the owner after completion of work);

- the amount of water needed daily for household needs.

Well pump calculation

Choosing a pump or other equipment for a particular well is a very difficult task. It requires accurate engineering calculations based both on the parameters of the well itself and the volume of water consumption by the household, as well as done using diagrams, formulas and tables. Only a system of autonomous water supply selected in such a way and mounted by specialists will be guaranteed to function even during maximum water consumption. An accurate engineering calculation will help you choose the type of pump for the well. Companies specializing in well arrangement, as a rule, have these specialists in their staff.

An approximate independent calculation is also possible. It is produced according to two main parameters: pressure and flow. Consumption, or productivity, is an indicator of the volume of water that a pump can pump per unit of time. Pressure is the height in meters to which the appliance is capable of delivering water. There are average indicators of the norm of water per person per day - this is 1 cubic meter (washing, taking a bath, washing dishes, cooking and more). To calculate the water needs of one household, 1 m3 is multiplied by the number of people living in it. For example, for 3 people a day, 3 m3 of water will be enough. But a maximum indicator is also needed, that is, if all households use water at the same time: the first uses a shower (10 l / min), the second washes dishes in the kitchen (6 l / min), the third lowers the toilet (6 l / min). Total - 22 l / min.

So, a family of three has 3 m3 of water flow per day and a maximum flow rate of 22 l / min. But this is only part of the expense, because in the summer you need to water the plants on the site, fill the pool, wash the car and more. There is a certain average indicator - 2 m3 per day. Total results: 5 m3 - daily water consumption. In order to determine the maximum characteristic of the pump head, it is necessary to increase the height of a particular house in meters by 6 meters and multiply by the pressure loss coefficient in an autonomous water supply system equal to 1.15.

Suppose that the calculation is carried out for a 9-meter house: (9 + 6) * 1.15 \u003d 17.25. This is the minimum pressure characteristic that a pump must provide for providing water to the house. And this pump, capable of delivering a pressure of at least 17.25, should at the same time provide a capacity of 1320 l / h (22 l / min). But that is not all. It is necessary to add to the design pressure the distance from the water mirror in the well to the surface of the earth. Suppose this figure is 40 meters. Therefore, for this autonomous water supply system, it is necessary to install a pump with a pressure of 40 + 17.25 \u003d 57.25, which can deliver a capacity of at least 1320 l / h.

If the well is not near the house, but at a certain distance from it, in this case you need to understand that for every 10 meters of water supply going horizontally, about 1 meter of the pressure of the device is lost. That is, if the source of water supply is 50 meters away from the house, then the pump should have a pressure force: 57.25 + 5 \u003d 62.25 meters. Correctly calculating the pressure characteristic is extremely important, but productivity can be slightly less, since the simultaneous use of water by all households is extremely rare. And the maximum accumulator in such a case can provide a hydraulic accumulator.

Pump types

Depending on certain operating conditions, it is necessary to choose pumps of the type corresponding to them:

- submersible;

- superficial;

- pumping stations.

How to choose a pump for a well from the proposed variety of types?

Surface pumps

Surface pumps are attractive in that they have a low cost. This type of device is designed to work without immersion in liquid. They are not designed to raise water from great depths - the optimum is 7 meters. In order to increase the suction power, craftsmen resort to various kinds of tricks, for example, apply an external ejector. In any case, with increasing depth, the capacity of the surface pump decreases. And at a depth of 25 meters, the prices of surface pumps no longer differ from more expensive types. But for working at a depth of up to 7 meters, such models are recommended, otherwise the water will be dirty.

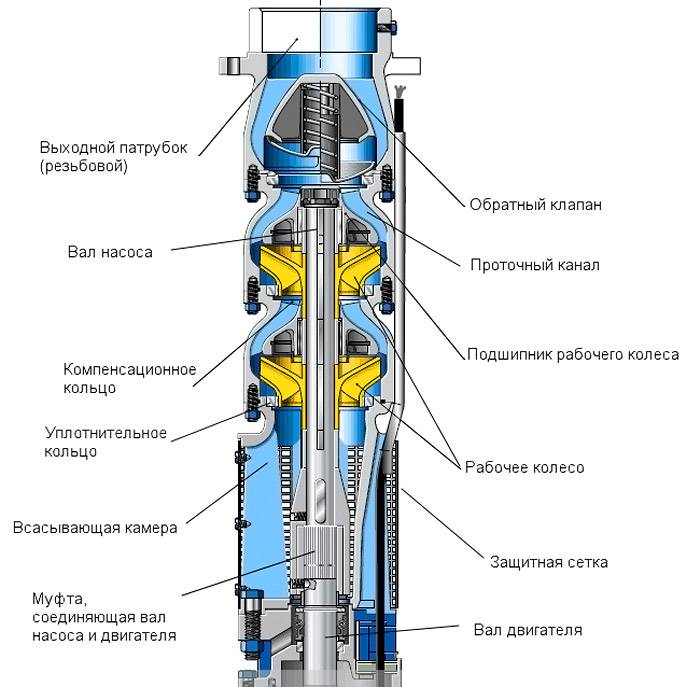

Submersible Pumps

These pumps operate with full or partial immersion in the water that is pumped. In this regard, materials that are not subject to corrosion are used for their production: stainless steel, waterproof composites, plastic and more. It is impossible to say unequivocally that it is them that must be used in wells, but the greater the depth, the more preferable to use this particular type of device. Fundamentally, this type is divided into three large groups according to the method of pumping water: centrifugal, vortex and screw.

- Centrifugal devices. They are used in cases where the water in the well contains a lot of sand (up to 180 g / m3). The pumps are equipped with special protection against serious damage in case they fail. Designed for pumping water from very deep wells. The fluid head in centrifugal pumps exceeds 100 meters. Key benefits: reliability and performance. These pumps are universal and are by far the most popular.

- Vortex devices. Designed for lifting water from a depth of not more than 30 meters, but to a height of 100 meters. Pumps can pump liquid with a low admixture of sand (up to 40 g / m3). The principle of operation of vortex pumps is that the functional wheel causes turbulence of water and thus carries out its pumping. This type is recommended for use in wells with a small debit of water, since they are able to create sufficient pressure with a small flow of fluid. But the performance (flow rate) of vortex pumps is much lower than centrifugal pumps.

- Screw devices. Designed for lifting water from a depth of not more than 15 meters to a height of 90 meters. They can work with water having a low admixture of sand (up to 40 g / m3). They are characterized by low cost and the ability to work not only in wells, but in open waters.

Pipes for a water supply system

For normal operation of the system, it is necessary to provide a high-quality pipe system that can adequately pass water at a certain pressure, which creates a specific pump model. Today, metal and polypropylene pipes are used. The latter are much lighter, more environmentally friendly, easy to transport and install, their connection is characterized by greater strength. The disadvantages of polypropylene pipes are: fragility at low temperatures and the ability to work only with nominal pressure (it is indicated by the manufacturer in the passport).

What factors should be avoided when operating pumps

- Work in the absence of water (the so-called "dry run") leads to overheating of the pump motor, since the pumped liquid also serves as a cooler. The same moment is also harmful for the sealant, which dries without passing liquid through it.

- When the “dry pump” is turned on, a water hammer occurs. Residual liquids hit the blades violently and can damage them.

- When the “dry pump” is operating, an air bubble may enter the intake hose, which is also accompanied by a water hammer.

- Freezing of liquids is unacceptable, this entails serious damage to the device. If the pump is stored in an unheated room at a temperature below 0 degrees, all water must be drained, and the device must be pre-dried.

- Exceeding the permissible temperature entails overheating of the engine.

- In no case should you save on pump power. Otherwise, the household’s autonomous water supply system will not be able to flush purification filters during regeneration.

- It is also worth remembering that some manufacturers in the instructions indicate the maximum parameters of the devices instead of the working ones - nominal, which leads to low performance during operation.

Unfortunately, with no type of pump does so many failures and failures occur as with household submersible borehole pumps. The reason is not the quality of the equipment, but the fact that the project and selection are carried out not by professional designers, but by the owners of private houses or insufficiently qualified personnel of installation organizations.

How, for example, does a specialist not know that a motor with a large supply of a pump can burn out if the pump is not brought into the operating range during installation and configuration of the system.

We hope that this article will help readers avoid such errors.

Parameter Definition

In all cases, for the correct selection of the pump, first of all, it is necessary to determine its operating parameters - flow rate (Q) and pressure (H).The required water flow rate is determined from the total productivity of all the water points of the object, taking into account the probability of their simultaneous use.

In a simplified calculation, you can use the following water consumption standards for plumbing fixtures:

- washbasin - 60 l / h, - flush toilet bowl - 83 l / h, - kitchen sink - 500 l / h, - shower - 500 l / h, - bathroom - 300 l / h, - watering tap - 1080 l / h

Watering lawns and flower beds requires 3-6 m3 of water per m2, the flow rate also depends on the method of irrigation and the intensity of irrigation. A sauna or bath will require about 1000 l / h.

To calculate the required pressure, the formula is used:

Ntr \u003d Ngeo + S + Hsvob, where

Ngeo - the height of the pipeline entry in the building relative to the dynamic water level in the well (a numerical expression of the dynamic level must be present in the passport of the well);

S - the sum of the friction pressure losses in the pipeline and local resistance (fittings, fittings, filters, etc.);

Nsvobod - the pressure that must be created at the entrance to the building, with the calculation of the provision at the most remote and highly located water folding pressure point of 0.5 atm.

Well parameters are fundamentally important for the user, as they are used in calculating the required head and operating characteristics of the selected pump. In the borehole passport, the drillers should indicate such parameters as the static level, dynamic level, and well flow rate. These data are determined experimentally by the organization that carried out the drilling work. Obviously, the calculation results will turn out to be incorrect if, when determining the dynamic level of the well, a pump of obviously lower power was used than would be required for the water supply of the facility in accordance with the needs of the consumer. And although it is difficult for the user to count on the quick receipt of an official passport of an artesian well (this is a state document requiring a lot of permits and approvals), it is necessary to require providing detailed data on the well with the act of work done, including asking about the capacity of the pump that was pumped water when determining the dynamic level. When concluding a drilling contract, you should pay attention to the availability of a license from the contractor. Only serious companies always upon completion of work give the client a guarantee and a detailed passport of the well, where all the mentioned characteristics are clearly stated, as well as the diameter of the casing string, a list of passed soils, information about the test pumping of the well, etc. - up to the recommended brand of the pump and its installation depth.

The parameters required by Q and H for additional equipment (Jacuzzi, washer, sprinklers, sprinklers, etc.) are specified by the manufacturers. When installing water treatment filters, pressure losses (usually about 2 atm) and the water flow for washing them are taken into account. For the pool, only the time of filling is indicated.

Calculation Example

Initial data:It is required to provide water supply to a suburban area with a two-story cottage (a kitchen, two bathrooms and a shower with hydromassage require a flow of 1 m3 / h and a pressure of 4-5 atm.), A garage, a house for staff (contains a bathroom), a bathhouse, a 45 m3 pool, irrigation of the territory, water treatment system. A family of four and two staff members constantly live on the site. A well with a depth of 80 m was drilled for water supply to the site; casing string diameter - 150 mm; static level - 46 m; dynamic level - 50 m; the flow rate measured during pumping is 3.5 m3 / h.

Payment:

Given the norms of water consumption (see the beginning of the article) we obtain the total consumption and pressure of consumers:

Qsum \u003d 500 + 3 ґ (60 + 83 + 500) + 1000 + 1000 + 2 ґ 1060 \u003d 6500 l / h \u003d 6.5 m3 / h

NTR \u003d 50 + 8 + 20 + 2 + 30 \u003d 110 m

Due to the impossibility and inappropriateness of using all the water outlets at once, it is possible to determine the required flow rate as 5 m3 / h.

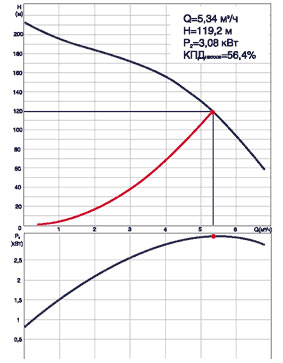

The calculated data are satisfied by the pump with (Q \u003d 5 m3 / h, H \u003d 120 m); its characteristic is shown in fig. 1.

This ensures sufficient consumption for the kitchen, one bathroom and watering. (It is understood that the owners will not simultaneously use the bathhouse and take a bath, shower in the shower and fill the pool with watering the territory from both taps.) To ensure pressure on the watering systems and hydromassage it is cheaper to use separate pumps - this will allow not to keep the entire water supply under high pressure and will make the work of the submersible pump more stable, and the system flexible and independent (with the help of an additional pump you can always get high pressure at any point of analysis). The pool will be filled at night. At the same time, with the help of a valve on the head, the pump should be “throttled” (to create additional resistance), so that when filling the pool, the flow rate does not exceed the permissible value - 6.5 m3 / h.

If the power is too high

Fig. 1. The performance of a properly selected pump.

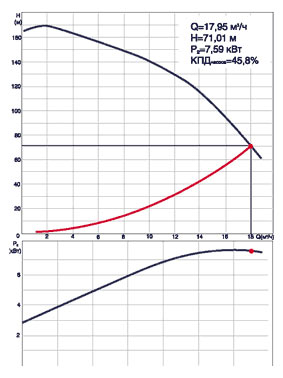

Independent choice of the pump by the customer, imposing excessive requirements for flow and pressure, often leads to the choice of a pump of too high power. As already mentioned, complications are possible when installing an overpowered model.

Firstly, since with such a choice, the nominal flow rate significantly exceeds the average water requirements, the pump will operate in the frequent on / off mode. Manufacturers allow up to 30 pump starts per hour, but only for one hour a day, with a general limit of 60 cycles per day. In any case, frequent switching on adversely affects the life of the electric motor and starting automation. To avoid this, a large volume membrane tank will be required.

Secondly, with an overestimated power of the pump, as a result, the water pressure at the entrance to the house will also be overestimated. At the time of starting such a pump, inevitable strong hydraulic shocks will occur. Some fittings may simply not be designed for such pressure (dishwashers and washing machines, faucets), additional installation of pressure reducers will be required to reduce the pressure.

Fig. 2. The pump is not picked up correctly: the operating point is shifted to the right.

Thirdly, during the filling of the pool, the pump will work on the "open pipe" without creating pressure. Under such conditions, there is a large flow of water at minimum pressure. The operating point of the pump is shifted to the right on the curve of the characteristic, in the region that does not correspond to the working area of \u200b\u200bthe pump (Fig. 2). The power on the shaft will be maximum, and with prolonged operation in this mode, the engine will fail.

The consequence of using an overstated pump will be the general rise in price of the entire system, caused by the use of more powerful electrical equipment, materials and fittings with greater permissible working pressure, an increase in the diameter of the pipeline and well, as well as the cost of water treatment.

If the nominal pump flow exceeds the well flow rate, additional dry run protection is required. Throttling and adjusting the pump will result in excessive energy consumption.

In other words, while ensuring the simultaneous use of all water points through the installation of an overpowered pump, the cost of the water supply system increases. At the same time, real water consumption will be significantly less.

Therefore, although the final choice will always remain with the customer, it is cheaper and more correct to choose a pump taking into account real needs and with the help of specialists. It is possible to satisfy the user's requirements for the water supply system while observing the rules for its installation and operation by choosing the pump with a gentle operating characteristic that is optimal in this situation.

For a water supply system, a pump can be selected from the above example (Fig. 1). In the zone of possible flows (from 4 to 8 m3 / h) in this model, the pressure dependence of the pressure curve has a flat shape, that is, at low water flows there will not be too much pressure increase. At the same time, a certain margin in calculating water consumption will eliminate the possibility of water shortages.

Pump installation and commissioning

In any case, no matter which pump is selected, during installation it is necessary to verify its operating point in all possible operating modes. When commissioning, it is necessary to measure the supplied flow rate (determined by the filling speed of any container of known volume, for example, barrels), the generated pressure (as indicated by the pressure gauge on the head) and the current consumed (measured by current forceps).The obtained characteristics are verified with the pump data sheet in the catalog. If the operating parameters are exceeded (as a rule, a certain power reserve is provided, for example, for the subsequent installation of filters), it is necessary to close the gate valve at the well exit and create additional local resistance sufficient to establish the correct operating point - the middle of the Q (N) characteristic.

Installation, as well as the choice of the pump, must be carried out by trained specialists, the installation company must have a license to install this equipment.

Well pump protection

Before choosing and purchasing a pump, it is necessary to obtain accurate information about the supply voltage at the facility. This is especially important when choosing an imported pump. All equipment supplied from abroad primarily corresponds to the industrial standards of the producing country. So for all German pumps, the permissible deviation of the voltage in the electric network from the nominal value is from +6 to -10%. Despite all the built-in protections, the pump is not intended for operation from a network with a voltage below 200 V, all possible voltage drops and surges will adversely affect the life of the electric motor. Adjustable voltage protection should be provided here as part of the control cabinet, and for three-phase pumps also against non-phase operation. It is not recommended to install powerful single-phase pumps. The starting current of the 2.2 kW motor can exceed the rated one by 4.4 times! To stabilize the voltage within the operating range at such surges, a stabilizer with a five-fold power margin will be required (more precisely, the manufacturers of stabilizers will make a choice). Sometimes it is cheaper for the user to provide 380 V power to the facility than the correct operation of a single-phase pump.According to statistics, about 85% of failures occur precisely with the electrical part of the pump. The main reason is the interturn closure of the stator windings due to overheating due to hydraulic overload, or when operating at low or spasmodic voltage. Both can be avoided by setting proper current protection. A conventional starter with overcurrent protection fully copes with this task, however, some installers forget to adjust to the required current value. The result of such negligence is easy to calculate: you will have to pay for lifting the pump from the well, repairing it (the price of a new engine), for lowering the pump again and putting it into operation. The amount may exceed the cost of a new pump.

Glossary of Terms

An individual building water system operating from a well in the area is the best option. With its help, it is possible to achieve complete independence from specialized services by providing housing with the necessary volume of water. However, before the device you will need to purchase certain equipment that must meet the assigned tasks.

The system can be organized in different ways. The simplest, but not the most successful, is the option in which water is supplied from the well to the places of consumption without additional devices. This scheme involves frequent turning the pump on and off during operation. Even with a short opening of the tap, the pumping device will start up.

The option with direct water supply can be used in systems with minimal branching of pipelines, if it is not planned to live permanently in the building. When calculating the main parameters, some features should be taken into account. First of all, it concerns the created pressure. Using a special calculator, you can quickly make calculations to determine the outlet pressure.

Well pump head calculation calculator for direct water systems

On the main features of the calculations

With permanent residence and the presence of a large number of water points in the building, it is best to arrange a system with a hydraulic accumulator, which reduces the number of duty cycles. This will positively affect the life of the pump. However, such a scheme is complex in the device and requires the installation of additional capacity, therefore, sometimes its use is impractical.

In a simplified version, the accumulator is not mounted. The control relay is adjusted so that the suction device is turned on when the tap is opened, and the shutdown is turned off when it is closed. Due to the lack of additional equipment, the system is more economical.

In a similar scheme, a well pump should:

- ensure high-quality water rise directly to the highest point without any interruptions;

- overcome without unnecessary difficulties the resistance inside the pipes that run from the well to the main points of consumption;

- create pressure in places of water tapping, providing the opportunity to use various plumbing fixtures;

- provide at least a small operational reserve so that the well pump does not work at the limit of its capabilities.

If the calculations are carried out correctly, the equipment purchased will allow you to create a reliable system that provides water supply to the places of water intake directly. The final result is issued immediately in three quantities, since any of them can be indicated in the technical documentation.