The scheme of connecting the accumulator to the pump and the water supply system. How to install a hydraulic accumulator for a water supply system: detailed video instruction

Installation and installation of the accumulator is carried out in accordance with the typical installation instructions. How to install a hydraulic accumulator right? An important condition for proper installation is to comply with the following rules:

- Installation of the accumulator must be started by putting down the initial pressure of the gas space in accordance with the values \u200b\u200bobtained in the calculations;

- in a system with a hydraulic tank, the installation of a safety valve is mandatory;

- on the pipeline, to the place of installation of the hydraulic tank and in the direction of movement of water, it is necessary to install a check valve;

- some of the manufacturers produce related fittings that can create water circulation through the tank during water extraction;

- a drain valve for draining the water and shut-off valves should be installed, protected from accidental closures (these manipulations are necessary for proper maintenance);

- the dimensions and weight of accumulators with a volume of more than 750 liters can significantly complicate your installation. Be sure to check if this container will pass in the doorway.

When installing, it is necessary to strengthen the hydraulic tank with a margin of safety. To reduce noise and vibration to zero, the tank should be fixed with rubber gaskets to the floor. It is also not bad to connect to the pipeline through flexible, also rubber adapters. An important condition is the cross-section of the inlet should not narrow at the entrance to the hydraulic system.

Another feature of the first filling of the accumulator with water must be done very slowly and with a weak pressure of water. The fact is that the rubber walls of the pear are still new, and can stick together, and the powerful pressure of the water can easily break it. Before starting operation, if necessary, all air inside the pear is removed. Failure to comply with these rules will lead to the fact that you will have to buy a membrane for the accumulator again.

Mount the hydraulic tank in such a way that they have free access. It is best to entrust this process to professionals, as they know how to install the accumulator correctly. Indeed, quite often even such trifles as a pipe diameter mismatch, or an unresolved low pressure, are often the cause of a tank failure. In such situations, experiments are not needed.

Membranes for accumulators

The membrane is an integral part of the accumulator. Its main purpose is to divide the tank into two chambers, air and water. Membranes are constantly exposed to temperature changes, compressions and stretchings, therefore, periodically (1-2 times a year) fail. Since the membranes cannot be repaired, if it breaks, you will need to buy a new membrane for the accumulator and replace it with the old one.

An indispensable device in modern water supply systems is not only a pump. Very often, it is supplemented with a hydraulic accumulator, which can go both complete with a pump, and be bought and installed separately.

Installing a hydraulic accumulator is a very useful solution that improves the quality of the water supply system. Let us consider in more detail how exactly this mechanism is arranged, how it works and how it is mounted.

1 The device of the accumulator and the principle of its operation

First, we describe the device of the accumulator: it is a container having a metal body, inside of which there is a membrane (or a cylinder, depending on the design). Between it and the walls of the body created pressure - thanks to the compressed air pumped into space.

Most often, the installation is used in water supply, however, it is also important to use a hydraulic accumulator for heating - it is also suitable for this.

The tasks of the mechanism are as follows:

- Accumulation of water.

- Maintaining a stable pressure in the system.

- Providing water to the system when the pump is not running.

The principle of operation is as follows: water enters the membrane pumped by the pump. The membrane fills and fills the space inside the body (of course - to a certain volume).

On the other hand, the injected air begins to press on the water, thereby forcing it into the water supply system. In this case, the pump runs until a certain point - until the water pressure inside the tank reaches a certain limit.

After that, the unit turns off, and the air acting on the membrane begins to “squeeze” water into the network. Well, when the liquid leaves the tank, and the pressure drops to a certain (only now minimum) mark, the pump will turn back on from the automatic control unit.

1.1 Classification of accumulators according to various parameters

The assortment of products on the market is quite extensive, so it will be useful for the buyer to first learn about exactly what they are, how they are classified, and which model is better to choose.

The differences lie in a number of factors, each of which should be mentioned.

According to the location of the container, the device can be either horizontal or vertical.

By the type of the working part - there may also be differences. In this regard, there are two variations: a membrane or a cylinder. In the first case, the space inside the container is divided into two parts by a membrane: in one - water enters, in the second - air is pumped.

In the second case, an elastic container is enclosed inside the container, into which liquid enters, and air is pumped into the free space between its walls and the walls of the body.

Separately, it is required to mention the volume - this is, in fact, a key parameter of any capacity. The most popular sizes are 24, 50, 100 and 200 liters. However, on sale you can also find tanks of a different volume - 6, 12 or vice versa - 300 liters.

There are also larger devices - for example, the Aquasystem hydraulic accumulator, which can be up to 2000 liters in volume. Reflex accumulator has a lower capacity - the largest model has a volume of 1000 liters. The Wester accumulator has the same limits.

Also, the material from which the membrane (balloon) is made deserves detailed attention. It can be either butyl or rubber. The differences are quite serious:

- butyl has an upper temperature limit of +99 degrees;

- in rubber, this mark is lower - only +50 degrees.

This is a very important nuance for those who choose a device for heating. However, most often devices of modern manufacturers (the same Aquasystem accumulator) use butyl.

And finally, it is required to mention manufacturers of products of this type. We have already mentioned several items that are most popular. These are the accumulator Wester and Aquasystem. Models of these brands are included in the high-budget segment, however, the quality is appropriate.

Hydraulic accumulator Reflex is already cheaper, but at the same time practically as good as. In addition to these names, one can also single out Dzhileks, which is quite popular in the Russian market for its positive qualities: cheapness and reliability.

1.2 How to correctly calculate the volume of the accumulator?

In principle, the main point that deserves attention is the volume of the tank. The membrane material (cylinder) was also mentioned above, however, such devices are used less often for heating, so we will focus on capacity.

It should be said right away that models of several hundred liters (for example, the Aquasystem VAV 2000 hydraulic accumulator for 2000 liters or the Wester Line WAV 1000 hydraulic accumulator for 1000 liters) are suitable for providing water to large buildings (hotels, hospitals, for example).

For an ordinary residential building, there will be a lot of such volume, and buying such a model will be an unnecessary waste of money. Moreover, they cost quite a lot: for example, the aforementioned Wester Line WAV 1000 accumulator will cost more than 10 thousand dollars, and the Aquasystem VAV 2000 accumulator will cost three dozen.

For a cottage in which 3-4 people live permanently, a capacity of up to 100-200 liters will be enough (and this is with a huge supply). Often, customers in such conditions are limited to models of 24-50 liters (for example, the Aquasystem VAV 50 accumulator or the Wester Line WAV 50 accumulator).

An increase to 100-200 liters is relevant if there are more inhabitants in the house, and / or there is a large number of water intake points (2 toilets and 5-10 taps - for example). In this case, pay attention to the Wester Line WAV 100 accumulator or the Aquasystem VAV 100 accumulator.

For accuracy, we give a more detailed calculation, which will help the buyer to more accurately choose a suitable device.

2 Steps and nuances of installing a hydraulic accumulator

With how to perform the calculation and how to choose a device - figured out. Now it is necessary to mention how exactly the connection of the accumulator to the water supply system is carried out. If you wish, this work can be done with your own hands - if you follow the tips below, then there should not be any difficulties.

It doesn’t matter which model is connected - a Reflex accumulator for a couple of tens of liters or a tank for 300 liters.

The preparation is as follows:

- First of all, you need to choose a place where the equipment will stand: an automatic water supply station and, in fact, the tank itself. They do not have to be located nearby, but most often this is done in this way.

- The pressure inside the tank is checked. It is necessary that this indicator be approximately 0.2-1 atmospheres lower than the parameter set on the automatic pump start relay. Otherwise, it can (and should) be adjusted with your own hands.

Now you need to take care of the necessary details for the connection:

- The fitting having 5 exits: for the tank itself, for the relay of automatic inclusion, for the manometer, for the pump and, actually, for the water supply line itself.

- Pressure gauge (with a scale of up to 10 atmospheres).

- FUM tape (for sealing compounds).

Now - consider how you can make a connection with your own hands:

- The fitting is connected to the tank using a hose.

- The pressure gauge, relay, pump and water pipe are connected to other outputs of the union. Each connection is pre-sealed with FUM tape.

Upon completion of the work, a test run of the pump should be performed to determine the tightness of the system. This requires a thorough inspection of the connection points: there should be no leaks.

When connecting a pressure switch with your own hands, be sure and very carefully look at the marks that are applied under its cover. There are two of them. "Network" and "Pump", and you can’t mix them up in any case. It is possible that these marks will not appear at all (this happens on some models) - in this case, it is recommended that you do not do the connection yourself, but use the help of an electrician.

2.1 Description of the device and the principle of operation of the accumulator (video)

It is enough to delve into the principle of operation and the device of the accumulator to understand for yourself how important this unit is for water supply systems in a private house.

1

Any owner of suburban housing is well aware of how difficult it is to ensure the stable operation of autonomous ones. Disruptions in water supply occur quite often. They lead to the failure of expensive household appliances and significantly complicate a person’s life in a private house.

Sometimes a single pressure surge is enough for a gas water heater or a newly acquired dishwasher to break. A hydraulic accumulator for water supply systems, called in the home an expansion, pressure or storage tank, helps prevent such troubles.

Accumulator for water supply systems

The main tasks of such a device:

- Support in the water supply network of a constant pressure value, protection of the system from its differences. With the simultaneous operation of 2–3 taps (for example, in the kitchen and in the bathroom), significant temperature fluctuations are observed during water pressure surges. If you take a shower or wash dishes at this time, there is a high probability of getting a burn. The installation of an expansion tank for water supply systems allows preventing such unpleasant situations.

- Protection against early operational wear of the water pump. There is always some water in the accumulator. When the crane is opened, it is she who begins to enter the network in the first place. In this case, the pump does not turn on until the water supply in the storage tank is completely exhausted.

- Pipeline protection against water hammer. They are often fixed at the start of the pump and cause significant damage to the water supply system.

- Providing consumers with a certain supply of water in case of a power outage when the pump is not functioning due to lack of electricity. Water, thanks to the installed tank, is still available in such situations. Its specific amount depends on the volume of the accumulator (100 liters, 200 liters and so on).

As you can see, the considered hydraulic tank is really of great importance for the normal functioning of water supply systems in private dwellings, especially if they are located outside the city.

2

By the type of energy storage, the devices we are interested in come with mechanical and pneumatic storage. The first of these functions due to the kinetics of the spring or load. Mechanical tanks are characterized by a large number of operational shortcomings (large geometric dimensions, high inertia of the systems), so they are not used for domestic water supply systems. It is worth noting that such devices do not need recharging and power from external electrical sources.

Units with pneumatic storage are more common. They operate by compressing water under gas pressure (or vice versa) and are divided into the following types: piston; with a pear or with a balloon; membrane. Piston units are recommended for cases when you need to constantly have a sufficiently large supply of water (500-600 liters). Their cost is low, but in private homes such installations are extremely rare.

The membrane tanks are small in size. They are convenient to use. They are most often used for water supply systems of private housing construction. Actively used and simpler balloon units. Such devices are easy to install (you can install them yourself) and maintenance (if necessary, any home master can easily replace a rubber bulb that has failed, or a leaky tank). Although the need for repair of hydraulic accumulators is rare. They are truly durable and reliable.

Membrane tank for a private house

By appointment storage tanks are divided into such types:

- for heating systems;

- for hot water;

- for cold water.

And according to the installation method, vertical and horizontal units are distinguished. Both the first and second function exactly the same. Vertical tanks with a volume of more than 100 liters usually have a special valve. It makes it possible to bleed air from the water supply network. Horizontal devices are equipped with a separate mount. An external pump is fixed to it.

Also expansion tanks for vary in volume. On sale there are very small units, designed for 2-5 liters, and real giants for 500 or more liters. For private homes, it is recommended to purchase hydraulic accumulators of 100 or 80 liters.

3

Diaphragm accumulators are a container inside which a special rubber gasket is installed that separates the tank into two functional parts. Inert gas or ordinary air is pumped into one part, and water is in the second.

The unit under consideration is equipped with a manometer showing air pressure, as well as a special hole through which water is supplied. Its injection into the tank is due to the action of the electric pump. If the hydraulic tank for water supply systems is equipped with automatic devices, they independently turn off the pumping equipment when the specified pressure indicator is reached. In this case, the water ceases to flow into the tank.

Tank device

The pressure in the tank decreases with each flow rate. When it becomes the minimum allowable, the automation starts up the pumping equipment again and pumps water. As you can see, the principle of operation of the accumulator is very simple. Even a person who is very far from the intricacies of water supply systems and equipment for them can easily deal with this issue. The arrangement of tanks with a pear or a cylinder (they are most often made per 100 liters) differs from membrane tanks in that they do not have contact of the liquid with the container body. In balloon units, water enters the pear, and then is consumed as intended.

An important point! Membrane tanks with a capacity of more than 100 l are always supplied with a bleed valve. In hydraulic accumulators with a smaller displacement, there is no such additional element. Therefore, during their installation, it is necessary to equip the water supply with a faucet or a special tee, with which it will be possible to block the main line of the network, and then bleed unnecessary air without problems.

4

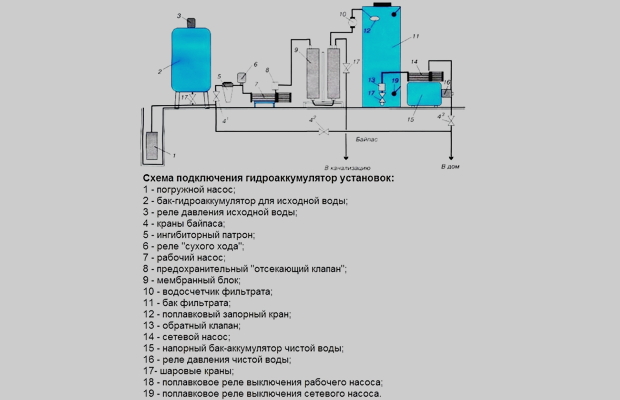

Cylinder and membrane containers are mounted by two methods. If you use surface pumping equipment, the accumulator is connected as follows:

- Determine the pressure inside the tank. Its indicator must be lower by 0.3–1 bar of the pressure required to start the pumping equipment (a specific number is usually indicated on the pump relay).

- Connect the union to the hydraulic tank. It should have 5 outputs - for connecting a water pipe, pump, storage tank directly, pressure gauge, pump unit and relay. The union is connected to the accumulator through a flange, which is equipped with a special valve (bypass) or a rigid hose.

- Screw all other system elements to the fitting.

- Seal all joints with tape or sealant and tow.

The accumulator connection diagram

When installing equipment, pay special attention to the connection of the pressure switch. Under its cover there are two contacts - a pump and a network. You need to bring a wire to each of them. This is easy to do if the contacts are signed. Otherwise, you will have to call a professional electrician. After installing and connecting the tank, be sure to check the system for leaks. If there are any, seal the joints better.

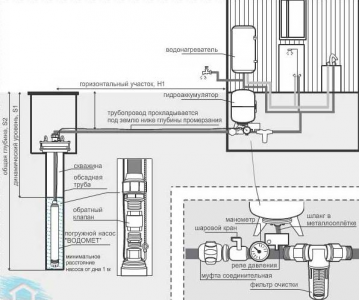

Connecting the storage tank to has some features. Such pumping equipment is installed in a well with water or in a well. In this case, a check valve must be mounted. It is placed on the pump (through the internal thread made in the cover of the device).

A valve is needed to prevent the backflow of water into the well. This is his only task. After installing the check valve, the hydraulic tank can also be connected to the water supply system according to the scheme already known to you. Now you know everything about the principle of operation, the device and the intricacies of the installation of storage tanks. Feel free to install the accumulator, so that in your home there will never be any interruptions in water!

The stability of the water supply depends on which water supply scheme of a private house you choose. Also, do not forget about ease of use and profitability.

A hydraulic accumulator is an important part of the water supply system of a private house. It contains water and compressed air. They are separated by a special membrane. As soon as the pressure drops, the pump turns on and fluid enters the system. Due to this, the pressure parameters are quickly restored and the flow resumes.

As soon as the pressure in the accumulator reaches the desired level, the flow stops. To prevent frequent switching on of the hydraulic apparatus, which is an important part of the water supply scheme of a private house, the water flow goes directly from the accumulator.

Important ! The hydraulic accumulator can provide operation of the entire water supply system of a frequency house even after a power outage. At the same time, the battery life depends directly on the volume of the tank.

Features of hydraulic accumulators

What are hydraulic accumulators used for?

The device must maintain a constant pressure in the system. This is his main task. However, for this to become a reality, certain conditions must be met.

Important ! To ensure strong pressure inside the system should be at least one and a half atmospheres.

In order for water from the tap to flow immediately after turning on the apparatus with a good pressure, the system must initially have sufficient pressure. The pump is responsible for it. The role of the hydraulic accumulator is to prevent premature burnout of the device.

The reason for the frequent operation may be that the performance of the supercharger is higher than the water flow. When the valve is open, the station creates the desired pressure, it automatically shuts off and the device immediately turns on again, as the pressure in the pipes decreases.

Very often, a hydraulic accumulator is used to ensure that water is in the entire building even with the lights off. Usually you need at least one hundred liters to cope with the urgent needs of a family of three.

A hydraulic accumulator is needed to prevent water hammer. When a sharp surge of voltage occurs in the network, and air accumulates in the system, frequent tripping of the pumping station will lead to the destruction of the supercharger blades. This, in turn, will cause a breakthrough in the pipeline.

What are hydraulic accumulators, and what are they

To create the most reliable water supply system for a private house, a hydraulic accumulator is needed. Therefore, it is very important to choose a device that is best suited to your needs during the purchase process. To do this, you need to know the basic structural elements of the unit, these include:

- case with legs,

- membrane or rubber bulb,

- nipples for air injection,

- protective cover.

Of course, each manufacturer of accumulators for water supply schemes of private houses is trying to bring something new to the structure, in order to achieve greater productivity and reliability of the system.

Take, for example, horizontal hydraulic accumulators. They are complemented by a tap or valve for bleeding air. Units for drinking water deserve special attention. The equipment is supplied with pears from special grades of rubber. This material has neutral chemical properties. Therefore, the liquid does not have any odors or taste.

Important ! If the accumulator is part of the heat supply scheme for a private house, then it must have an expansion tank.

Depending on the type of location, horizontal and vertical hydraulic accumulators are distinguished for water supply schemes of a private house. The first are used in the installation of external systems. The pumping units are installed directly on the hydraulic equipment. The vertical arrangement is used in water supply systems with submersible pumps.

Depending on the purpose, there are three types of accumulators for water supply schemes of a private house:

- for supplying cold water;

- for supplying hot water;

- for heating systems.

Naturally, the design of the units is very different from each other. Accumulators for hot water supply of private houses use materials that can withstand high temperatures. In addition, they are installed only when installing a complete system (when there is hot and cold water).

Attention ! Heating accumulators are painted in red, and for hot water and hot water in blue.

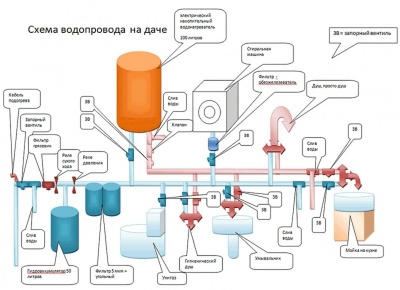

We create a water supply scheme

Laying pipes in a private house can be carried out in two main ways: by means of a serial connection or a collector connection. The first option is ideal for a small country house. To justify the scheme - no more than two people should live in the room.

Attention ! For cottages with a large number of permanently residing people, a consistent scheme for connecting the water supply of a private house with a hydraulic accumulator is not suitable.

A consistent piping scheme is based on the fact that water flows through the main pipeline. A branch tee is placed near each consumption point. When several channels are used at once, the pressure drops. As a result, the farthest user does not receive water.

The collector circuit is built on a completely different principle. Pipes are diverted from the common collector to each consumer. The result is an equally stable head in each valve.

Attention ! The cost of creating a collector circuit is much more expensive due to the large number of pipes.

Now in most private homes they install a collector water supply scheme with a hydraulic accumulator. It consists of the following elements:

- Well or well.

- Pumping station. A pipe is laid from the well or borehole underground and brought to the pump.

- Accumulator From it, a tee with a stopcock must be installed on the outlet pipe. In one pipe there will be water for the house, in another for technical needs.

- The pipe through which water is supplied for the water supply scheme of a private house is connected to a water treatment device.

- A tee is mounted at the outlet of the water treatment systems, separating hot and cold water.

- Pipe with cold water enters the corresponding collector. Stopcocks are installed.

- The second channel should go to the water heater and from here crash into the collector.

This is the basic water supply scheme of a private house with a hydraulic accumulator. If necessary, additional elements may be included in it to expand the basic functionality.

Connection

An important role in connecting the accumulator to the water supply of a private house is played by a non-return valve. It allows compressed air to squeeze water into the well using a membrane.

Important ! The valve is mounted on the pump. Moreover, this must be done before connecting the remaining elements in the water supply scheme of a private house.

For convenience, the connection procedure is divided into the following stages:

- First, a submersible pump is installed.

- So that everything goes according to the standards, the depth of the well is determined using a rope and a load.

- A place is marked on the rope to which the fluid pumping device must be lowered. It should be at a distance of no more than 30 centimeters to the bottom.

- After the pump is fixed, the pressure pipe is connected to the pressure switch via a hose. In this case, a fitting is used.

- The accumulator, which plays the main role in the water supply scheme and pipes leading to the points of consumption, are alternately connected to the fitting. The last connector is needed to connect the control unit.

All connections in the water supply scheme of a private house with a hydraulic accumulator must be reliably sealed. It is best to use a tow with sealant.

Summary

A properly designed water supply scheme for a private house with a hydraulic accumulator allows you to protect the pipeline from water hammer. It also provides a reserve supply of water for all occasions.

To use a hydraulic accumulator as an alternative source of water supply, a tank volume of at least 100 liters per three family members is required. For two, 50 is enough.