Price and variety of high quality well pumps. Submersible centrifugal pumps: design and use of pumps for wells and wells

Owners of many private houses prefer to get water for use themselves, without connecting to the city water supply. The reasons may be different - poor quality of tap water, savings, etc.

Technical characteristics of the pump should be specially selected for the size of the used area. Sometimes the depth at which the underground rivers pass is very large (in some places it reaches a hundred or more meters). Then the standard unit will not work.

For these purposes, there are special deep models. They are usually used in large enterprises for the extraction of artesian water.

Device and principle of operation

Depth devices have not only excellent characteristics, but also differ among themselves in different designs that use different principles of work to raise water.

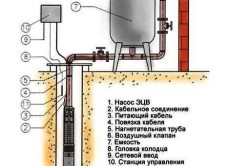

The entire installation with most of the main parts is below the surface of the water. And from the pump in a dense insulated winding lies a wire and a pipe for supplying water.

The standard equipment assembly typically includes an engine and an internal filter. Fluid suction is from the bottom or top of the unit. If the unit has a lower suction, then it can well filter sand and silt from the underwater river.

Submersible pumps consist of two components:

- the pumping part itself with several stages;

- motor, which controls the rise of water and can be both built-in and outdoor.

Pump motors

Built-in motors are usually located below for maximum protection of the device against corrosion due to constant contact with moisture.

The upper part of the structure is occupied by the drive shaft device and certain blade branches.

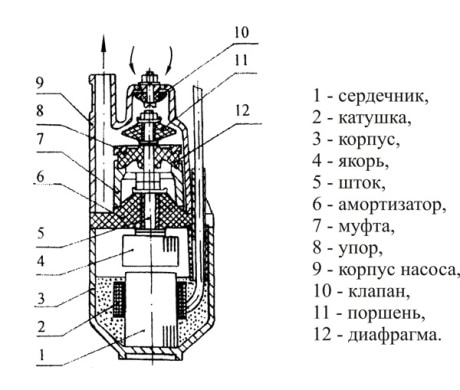

There is a special glass and case. A vibrator is built in there, which creates the necessary traction to create a stream of water, and there is also an electric motor. The vibrator is a rather complex design, but it plays a major role in the performance of the work. It consists of an anchor, a rubber shock absorber and adjusting washers.

Types of equipment

If you are inclined to buy such equipment, you should now understand in more detail its types in order to choose the most suitable for yourself.

If you are inclined to buy such equipment, you should now understand in more detail its types in order to choose the most suitable for yourself.

Paying attention is first of all to the technical specifications, quality and the manufacturer.

In this section you will learn about the features of different mechanisms for raising water.

Centrifugal

Devices of this kind are used to raise water for a long time without seasonal breaks.

Devices of this kind are used to raise water for a long time without seasonal breaks.

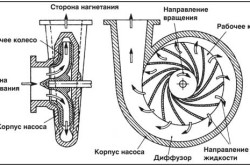

Such a device has 2 components - a hydraulic device and an electric motor.

The impellers rotate and due to this, a pressure difference is created in the pipe, which makes the water rise with sufficient force. It has the advantage of high performance, good traction and versatility in use.

Auger

This type of unit is manufactured for special purposes. Its main task is high-quality distillation of water with impurities.

This type of unit is manufactured for special purposes. Its main task is high-quality distillation of water with impurities.

If you pursue this goal and are thinking about buying such equipment, you need to know one important detail.

For an uninterrupted supply of fluid, you need to choose a device with a diameter of about 1 centimeter less than the diameter of the casing. Otherwise, the pump will become clogged with various impurities.

Screw

The main advantage of this model is that these pumps squeeze a lot of pressure even with small volumes of water supply.

The main advantage of this model is that these pumps squeeze a lot of pressure even with small volumes of water supply.

The design of the apparatus consists of an impeller with many blades, which is placed in a cylindrical body.

Thanks to the circular rotation of the blades, water is supplied. Of the disadvantages of this type, it is worth noting the complexity of the work when using liquids with impurities.

Other models

The manual unit can only be designed for a limited depth of water production. It can be used if the water lies no deeper than 25 meters from the surface.

The sucker rod pump is usually large and very rarely used in household appliances. They can often be seen in places of oil production. The design of such a unit is quite simple, but it copes with the function of extracting liquid from the depths.

Mud immersion apparatus is used for all kinds of liquids of various degrees of viscosity. This is not the best choice for pumping water, but if you need to pump out water with many impurities of dirt and clay, then it will do just fine.

Which unit is better to choose

What is better to choose a pumping station or a depth unit?

Choosing a pump for a well or a well is not an easy task and requires special attention. Of course, the device must be reliable, efficient and, importantly, affordable. These requirements are met by modern submersible models capable of pumping a large amount of water for watering plants and domestic needs. In order not to get confused at the sight of a wide range and choose the best option, you need to clearly understand how the submersible pump works.

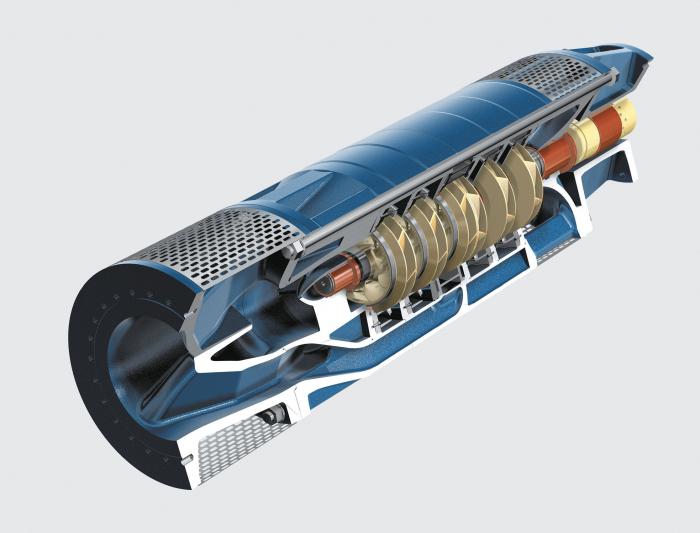

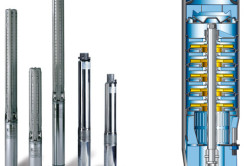

The most popular types of submersible devices are single-stage and multi-stage horizontal devices. They are able to work in difficult conditions (even in liquids with a high gas content) and to raise significant volumes of water from great depths.

The deeper the well, the more powerful the device should be. As a rule, the design includes several working stages, consisting of wheels and diffusers. The principle of operation of a submersible pump does not allow its use in dirty or turbid water: at each stage the pressure increases, and the strong pressure of water flavored with abrasive particles can damage the mechanism.

By the type of engine, rod and rodless models are distinguished. In the first, the motor is located separately from the pump itself, and energy is transmitted through a rod drive. In the second embodiment, the electric motor is located in the intake shaft.

The choice of submersible pumps is best left to a specialist

Well pumps

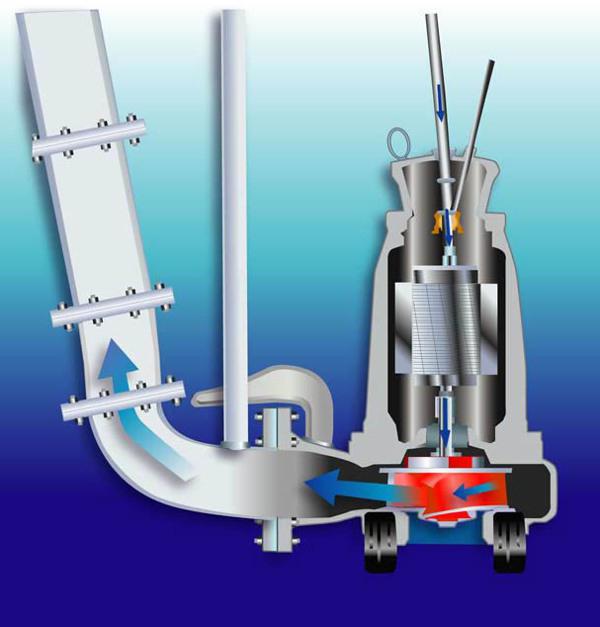

Well pumps are designed for intakes of a depth of not more than 50 meters. Most often, such devices operate on a vibrational type: the motor is placed inside the body of a rubber membrane, which changes shape and thereby “pushes” water upward. The inlet valve opens when the pressure decreases, the exhaust valve when it increases. A design feature is the large diameter, which significantly limits the scope of its application (wells and wide wells).

To avoid “dry running” and related breakdowns, the well pump must always be below water level. A critical level may be signaled additional devices: floats, switches or electronic automatic systems.

"Baby" - one of the most popular submersible pumps

Well pumps

Downhole devices operate in mines completely filled with water. Pumps equipped with a sealed housing with anti-corrosion coating are able to operate at a depth of 300 meters. The small size allows the use of submersible devices even in narrow artesian wells.

As a rule, centrifugal type models are suitable for deep water intakes, but in some cases it is possible to install a device with a membrane (vibration type).

The cost of the device depends not only on its power, but also on the quality of the materials used and the availability of an automatic control system. Centrifugal apparatuses are considered the most expensive: they work equally well in sand and artesian wells, and if necessary can be used for pumping oils and other viscous fluids.

Important! Do not purchase a pump before drilling a well. The depth of the aquifers can be very different from your expectations.

The principle of operation of a submersible pump

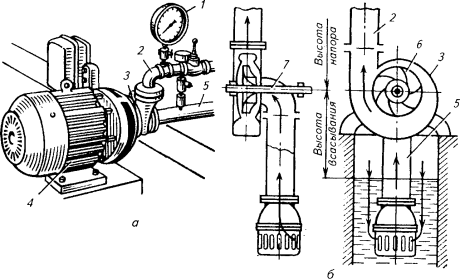

A classic centrifugal pump consists of a spiral housing and a multi-vane wheel (or several wheels) fixed inside. The blades are bent to the side opposite to the rotational movement of the wheel. The mechanism is connected to the pressure and suction piping through a pipe system.

The principle of operation of a submersible pump is quite simple. With the help of a motor, the wheels begin to rotate around their own axis, the blades located on them create a lifting (centrifugal) force, which moves the fluid along the sleeve. High pressure “pushes” water into the pipeline. Due to the design features, the flow “swirls”, therefore, at some distance from the sleeve there is a leveling device: water passes through it and then enters the pressure water supply.

Centrifugal pump works by rotating the blades

Vibrating instruments

The vibration pump consists of several elements:

- U-core electromagnet filled with a mixture of epoxy resin and quartz sand;

- Vibrator with a fixed rod (a rubber washer - shock absorber is installed on the back side);

- The forcing and soaking-up chambers;

- Piston washers (piston performance is regulated depending on their number);

- Check valves that hold water in the pipeline;

- Rubber piston;

- Pipes for draining fluid into the water supply.

Note! The most problematic places of the system are pistons and reverse valves: when heavily contaminated with water, the rubber deteriorates quickly and the pump fails.

Detailed vibratory pump design

The principle of operation of a submersible pump of vibration type is based on pressure differences:

- When connected to the network, the coil winding creates an electromagnetic field that attracts a vibrator located in the discharge chamber.

- The diaphragm bends, due to which the pressure decreases.

- Through the check valve system, water flows from the shaft into the suction chamber.

- After a few moments, the magnetization disappears, the rod is thrown back.

- The piston directs water to the suction chamber.

Magnetization and demagnetization occurs at intervals up to 100 times per second. The pressure drops form vibrations, which gave the name to the type of pump.

How to choose a submersible pump

Even the most expensive and powerful device will not bring benefits if you choose it at random. If you do not have the proper experience in water supply issues, it is better to give the selection of the pump to specialists. When buying, you must consider all the parameters:

- The distance from the water intake to the house;

- Planned volume of water consumption;

- The presence of a filtration system;

- The principle of operation of a submersible pump.

Based on these data, the necessary characteristics are calculated:

- Power (W or kW). Shows the volume of pumped water per unit time.

Important! Do not select power according to the principle "the more the better." Excess pressure only harms the water system.

- Throughput (cubic meters per hour). Shows the performance of the pump (how many liters the unit lifts from the well per unit time).

- The maximum pressure. The device should not only raise water, but also transport it to the "end user". The calculation includes the entire length of the "waterway" - from the bottom of the shaft to the mixer.

Important! For every 10 meters of water supply, you need to add 1 meter of pressure loss. If a filter system is installed in the house, multiply the loss by two.

After watching the video, you will get a complete picture of how the submersible pump works, how to choose and install the device in the well.

In addition to important nuances, you should pay attention to design features that simplify the operation of the device. So, a long insulated cable will allow you to use the electric motor in any weather conditions, and dry-running sensors will prevent breakage. Have a nice shopping!

How to choose the right equipment for the organization of autonomous water supply? Along with the arrangement of the source of water intake (well, well), special attention should be paid to the method of raising the liquid from them to the surface. To solve this problem, submersible centrifugal pumps are most often installed.

Destination

Autonomous water supply consists of several elements: a source of drinking water, a piping system and pressure generating mechanisms for transporting liquid. Their proper design and interaction with each other is the key to optimal performance.

Pumping equipment is the main part, which should solve the following tasks:

- The rise of drinking water from an underground source to its distribution system.

- Providing the required pressure and volume.

- Uninterrupted operation (in accordance with operating conditions).

- Maximum ease of management and process automation.

One of the optimal solutions that satisfy the above conditions will be the installation of centrifugal pumps. Along with a simple and reliable design, they have good performance properties. Their main area of \u200b\u200bapplication is raising water from wells and wells. Depending on the depth, submersibles of various capacities are installed. For artesian wells, this figure can reach 50 m. Wells in most cases have a depth of up to 7 m.

Operating principle

The basis for the correct selection and operation is a work scheme that distinguishes submersible centrifugal pumps from other devices of this purpose. Their design meets the operating conditions - being in a liquid medium, the housing must not be corroded. Since an electric motor is used as a power unit, its full waterproofing is mandatory in order to avoid breakdowns and malfunctions. Consider a submersible centrifugal pump device. A typical pump consists of the following elements:

- An electric motor is a sealed part of a pump in which a power unit is installed. Using the shaft, the rotational energy is transferred to the next node.

- Blade compartment - located at the bottom of the device. Designed to create pressure, due to which water rises.

- Pipeline - a transport unit for moving fluid to a consumer point - a home or watering system.

The pump is made of non-corrosive materials - high quality polymers or stainless steel. In the lower part of the housing are receiving holes that act as a filter. Large debris does not enter the pump. During the rotation of the blades under the action of centrifugal force, water masses move along the receiving chamber of the device. At the same time, they serve as an engine cooler, preventing it from overheating. For timely start (stop), water is connected to the pump control unit. In addition to them, external control elements can be connected to the system - a pressure switch in the water supply of the house or direct connection (shutdown).

Kinds

Depending on the technical specifications, submersible centrifugal pumps may vary slightly in design. When choosing the optimal model, one should take into account the composition and degree of water pollution, as well as its depth. The last factor will directly affect the power of the pump.

The design of household models is relatively simple: the engine, together with the impeller, generates sufficient water pressure during operation. They are simple, reliable, have small overall dimensions. But if the horizon of drinking water is deep enough, complex types of construction should be established.

To increase this parameter, centrifugal submersible pumps for water are equipped with a more powerful engine, or a vertical pulley with several impellers. Due to this, they create an increased pressure of water to raise it to the surface.

Similar designs are also used for pumping oil. They have good performance, and most importantly - reliable.

Specifications

The standard submersible is selected based on its technical characteristics. In this case, you should pay attention to the power indicator. It is a determining factor when choosing a specific device model. In addition to this, you must know the following device parameters:

- The volume of the pumped-over liquid - l / min.

- The height of the water column. Determines the maximum depth of the well (well) and the horizontal length of the pipeline.

- Additional equipment - water level sensors and emergency shutdown.

The case of most devices is made of stainless steel. In low-power models, designed for a small height of water supply, it can be made of polymeric materials.

terms of Use

Modern submersible centrifugal pumps must operate under conditions that are clearly specified in the instructions. Not only the quality of the device, but also its durability will depend on this. The main operational characteristics include the composition and temperature of the water, its degree of contamination. Special attention should also be paid to stabilizing the applied voltage.

Often submersible centrifugal mounted on personal plots, where current surges - a common occurrence. The electric motor does not have effective protection against such changes. Therefore, it is recommended to connect the device through the stabilization unit.

Installation

The basic installation rules are described in detail in the operating instructions. If you need to install a centrifugal then you should consider the system of its fixation. There is a special fastener on the pump casing. It is required to install a submersible cable.

The material of its manufacture must meet the following requirements:

- Do not corrode.

- The tensile load must be at least 5 times the weight of the device.

Never lower the device with the power cable. The main load should fall on the mounting cable. It is mounted on the surface: either to the transverse beam on the neck of the well, or on the outer protective walls of the well.

Service

The instructions also indicate the estimated duration of the preventive work. They mainly consist in checking the tightness of the housing, replacing the rubber seals on the engine stem and cleaning the connection contacts. In the event of an unforeseen breakdown, contact the representatives of the manufacturer or a specialized repair shop.

It should also be borne in mind that submersible centrifugal pumps can be optionally equipped with filters for pre-treatment of water. They are installed on the inlet of the device and replaced as they become dirty.

Before purchasing, you must clearly know the operating conditions under which the centrifugal submersible pump for the well will work optimally. To do this, it is recommended to adhere to the following recommendations:

- Water consumption. The water feed rate must comply with the design standards.

- The height of the water column. When calculating it, not only the depth of the well (s) is taken into account, but also horizontal sections. For them, a reduction factor of 0.1 is applied. If the well depth is 7 m, and the horizontal pipeline has a length of 12 m, then the minimum height of the water column of the pump should be: 7 + 12 x 0.1 \u003d 8.2 m.

- The presence of water level sensors in the kit.

- Warranty on equipment, remoteness of the service center of the equipment manufacturer.

Given these indicators, you can choose the best model pumping station, which will provide the proper amount of water. In addition, they can perform the functions of draining flooded cellars and cellars. The main thing is to take into account the composition of the liquid and the permissible norms of its contamination for a particular pump model.

Due to this, they create an increased pressure of water to raise it to the surface.

Consider the example of the Aquarius pump. This is a practical, simply arranged and most appropriate in the category of "price-quality" well pump device. It consists of two parts: a pump and an electric motor. The pump is driven by centrifugal force.

To calculate the pump power for water wells, you can use the calculator for calculating the pump power for water wells.

The pump consists of a shaft on which blades, impellers and drive rings are inserted, passing through the shell. Parts of the product are held in place by a cap with a female thread. At the switched on device, the wheels spin, create a centrifugal force that pumps fluid filling the inside of the shell.

The engine consists of a stator, a rotor, two ball bearings that spin in oil. Automation is made by the German manufacturer Thermik. It is trouble-free, independently controls the operation of the engine and protects it if you have to work to the limit. In order to control the operation of the pump there is a device for remote control connected to the power supply cable. This pump is designed to supply water from a depth of 1 to 20 m, the smallest allowable borehole diameter of 120 mm. It is possible to adjust the water pressure supplied by the pump using a special damper located at the end of the outlet hose. The device is suitable for lifting water in an amount of 360 l to 12 cubic meters per hour, the diameter of the hose should be more than ¾ inch. Considering working qualities well pump devices, it is possible to use it for pumping water from wells, natural reservoirs, other reservoirs, wells.

Connection and service of a borehole pump.

Before lowering it into the well, the Aquarius pump must be prepared:

The pressure pipe must be connected. The type of pipe to be connected depends on what needs the Aquarius pump to be used for. You can use a hose for irrigation, if it will be used for irrigation or water intake, or if it is planned to be used for work together with a hydraulic accumulator in a stationary installation - a metal or plastic pipe.

Install a check valve. When connecting a pump that operates in a closed pressure water supply system, a check valve must be connected. The check valve is not installed during production. There are two connection methods: by tapping into the pipe at a distance of less than 1 m from the outlet pipe or by installing the valve directly into the pipe. According to experts, the best choice would be a valve with a brass seat.

Accession of a cable. The cable is passed into special slots on the housing and is securely fixed. The cable can be used both from kapron and steel. It is strictly forbidden to raise or lower the pump by the wire. From practical experience it follows that it is best to fix the wire in the pressure pipe using the brackets designed for this - this will facilitate lowering and lifting the device and almost eliminate the possibility of mechanical damage. After that, the borehole pump device is connected to the outlet.

The device gently lowers into the well under strict control over the degree of tension of the pressure hose and electric cord. The device is mounted at the desired depth by a cable. The pump can be used.

Even taking into account the high reliability of the Aquarius pump and the fact that it can run smoothly for many years, it is recommended to inspect it from the well twice a year for damage. Inspect it from the outside. It is unacceptable to seize the axis of the engine during rotation, which should be light and soft. In the event that no jamming of the axis is detected and the device continuously pumps water under the required pressure, it should be installed in its place.

If there are any concerns about the correct operation of the device, it is necessary to continue the examination. provides for the possibility of a systematic inspection, and if necessary, replacement of rotation bearings. It is recommended to inspect the condition of these parts, the oil seal and check the oil level. If it is necessary, it is worth changing the seals and bearings, add oil to the desired level. It is worth looking at the motor winding and determining if there are any damage or signs of overheating. Dismantling the engine is a delicate matter: after all, the insulation of the wire after some time becomes brittle and easily damaged. The pump part does not require special maintenance, but, with a strong decrease in the pressure of the apparatus, it would not hurt to change the impellers - this may be due to wear.

Cleaning and minor repair of the well pump.

There are times when well pump device does not rotate and its owner has a need to disassemble the pump. Please note: the device does not have an internal filter, and the mesh that traps stones and coarse sand is attached externally between the engine and the pump part. For this reason, the cessation of rotation, as a rule, is caused by a breakdown or clogging of the impellers. Not a big blockage there is an opportunity to try to eliminate it yourself.

You need to clean in several stages:

Remove the protective net. In new models, it is fixed with a special clamp, which can be opened by prying off with a screwdriver or with a light pressure in the middle. On the old - there are two ordinary bolts that are easily unscrewed

On wide models of pumps, it is also possible to remove the cable channel - a small metal groove that protects the cord from defects.

The engine can be removed and disconnected from the pump part by unscrewing the four bolts with a 10 wrench. After that, the couplings that direct the motor power to the pump must be removed.

The disassembled apparatus is carefully laid on a horizontal surface. It is very important not to damage the cord.

Next, you need to rotate the shaft with a 12 head or a socket wrench, be sure to support the upper part of the device. When the shaft moves, you need to apply a stream of water to the pump part in order to remove parts from there due to which the device is jammed. After making sure that the shaft can spin, carefully wash the pump, and assemble it in the reverse order.

If it turns out that the impellers are broken, disassembly of the pump part is necessary. Assign these works to the service staff, since in this case it is necessary to replace broken parts.

It is not uncommon that the owner of a pump, noticing that the axis in the pump part does not rotate, decide that the bearing is jammed. But in the pumping part there is one plain bearing and therefore cannot jam. There is a problem with the impellers and they are best replaced. If there are spare parts, you can try to repair the pump yourself. To do this, you need:

- To rest against the brass part of the bottom of the apparatus and with effort to squeeze the shell from below and above.

- Using narrow teeth, remove the retaining ring. The ring is in a special groove and will loosen if you tightly compress the shell.

- Remove all impellers one by one, then remove the thrust cover with bearing.

- Eliminate the cause of jamming and fold the parts in the reverse order.

It should be borne in mind that in service centers there is a special press, with the help of which the pump is disassembled and assembled. Without such a press, at home, it is difficult to do, or maybe impossible.

In order for water to flow uninterruptedly to a site and a country house, it is best to use wells that supply water directly from deep aquifers. The arrangement of such wells is as simple as possible. They are a trunk that can reach from a couple of meters and up to 40 m. To ensure the water supply from the well is uninterrupted, it is necessary to install special equipment.

A variety of devices are used, including pumps, which can be surface or submersible. Surface mounted above the well, they are designed to work with shallow depths. These devices are good for a well, but for a deep well it’s better not to use them, they definitely can’t cope with the task. For such sources apply deep pumps. They are placed inside the well itself below the surface of the water, they can suck water from above or from the bottom. The design of the deep pump is simple, there are different models on sale. It’s not difficult for a well to choose an appropriate option.

Features of the deep pump and its characteristic

The design of deep pumps largely depends on the parameters, principle of operation, type of motor. This equipment is designed to lift water from a sufficiently large depth. In everyday life, they are used for wells, wells on sand or limestone. The name itself indicates that the equipment is immersed under the surface of the water mirror, the power cable in the protective sheath and the pipe that delivers the water goes from the device.

For control, special automatic units are used, but they are placed in the caisson. The pump itself is usually equipped with an engine, an integrated filter, water can be taken from the bottom of the equipment or from above. The first option is more preferable, since with the help of such a device the well can be cleaned from the mass of sand and silt. It should be remembered that the level of immersion is usually not more than 20 m from the surface. This is the limit value, which is calculated by the ratio of static and dynamic water levels.

The device for the well itself may include 2 parts:

- engine (internal or external);

- multi-stage pumping part.

If the engine is built-in, then it is placed at the bottom to protect it as much as possible from the negative effects of water. Further, in the upper part of the housing is the drive shaft of the equipment, working wheel guides, special blade bends. The vibration pump consists of a special cup and housing. There is a vibrator that creates the necessary pressure, and an electric motor. The most difficult element is the vibrator, which provides the rise of water. This includes the anchor, rubber shock absorber, adjusting washers.

The shock absorber is compressed during operation, creates the necessary conditions for water intake.

A centrifugal pump is a bit more complicated, but its operation is more reliable and durable, which is why many people prefer it. Attention here must be paid to the shoulder blade, which is attached to the motor. It depends on him durability and quality of work. The bearings, which are provided here, are effectively cooled by water, therefore, overheating does not occur. Often the pump has built-in sensors that allow you to immediately stop the operation of the equipment, when too much sand begins to flow, the water drops to an unacceptable level. When using pumping equipment for sand wells, it is necessary to provide for a filter that will protect the mechanism from the absorption of abrasive inclusions.

What affects cost?

The design of the pump has a certain impact on the cost:

- Specifications, water supply, performance and power. For downhole equipment, it is important how the water will be supplied and under what pressure this will happen.

- The type and power of the engine have always had one of the most important values. The more powerful the equipment, the more depth it can lift water, but its cost will be higher.

- The price increases with an increase in power by 4 thousand rubles for a difference of 0.75-1.5 kW.

- Resistance to pollution and sand. It is important to use a pump that will not break if there are sand impurities in the water. Pure sand will not be able to overtake a single pump, but there should be protection against it, especially for sand wells. For limestone sources, this does not matter much, but it is important to remember this when choosing. Sand protection is provided by a special integrated filtration system.

- Performance affects cost because the design of the pump is more complex.

Varieties of submersible pumps

The design of deep pumps depends in many respects on what type they are. There are 2 groups:

- by type of design and engine location;

- according to the principle of work, i.e. by how exactly water is taken.

When using the pump, it is important to pay attention that the design can be of different types:

- Rod pumps are maximally protected from the negative effects of water. The engine is not located inside the housing, but on the surface, separate from the device. The thrust is transmitted through a special rod drive to the pump.

- Rodless pumps have an engine that is attached to the housing, it is also in the water. It is this type of pump that is used most often, since it is more convenient to install, although its cost may be higher. A similar unit is used for wells of any type, often they are equipped with wells, sewer and drainage networks.

Such pumps are usually made in the form of a cylinder, the diameter can be up to 140 mm. For country wells, aggregates with a diameter of 100 mm are used. Their cost is optimal, the model range is represented quite widely.

Selection of pumps based on the principle of operation

The submersible pump may have a different design depending on the principle of operation. Vibration and centrifugal pumps are distinguished, which differ in their characteristics. All vibrating borehole pumps that are mounted in the wellbore differ in such features:

- They are resistant to environmental pollution, which makes it possible to use it for any type of soil.

- The range of devices is diverse.

- The cost of the vibrating device is not so high, often the electric cable for the pump costs more than the pump itself.

But there are a number of minuses that should not be forgotten:

- The capacity of this type of pump is low.

- Reliability and durability can not boast of anything special, the operating life of the vibration pump is small.

- During operation, the equipment vibrates. This circumstance is one of the most serious, since the walls of the well can begin to collapse, especially if there is no casing. The unit begins to swing during operation, its housing may be damaged. But then the cost of the device is low, it is this fact that often plays a paramount role when choosing equipment for wells.

A centrifugal pump is no less popular today, as it has a high level of efficiency, which makes it possible to purchase a cheaper device with a power level slightly lower. Centrifugal pumps can be multi-stage. This allows you to pump water at a higher pressure level, the performance of such devices is much higher.

Maintenance of the equipment is simple, as well as use, but it is precisely devices of this type that are sensitive to pollution, so it is necessary to use additional filters. The pollution norm for a centrifugal pump is up to 150 g / cc of liquid, but there are also special pumps that can operate in case of contamination of 20 kg / cc. The cost of this equipment is high, for small wells such pumps are not used.

Using a downhole pump for a well requires a careful selection of the device. It should be understood what exactly is a pump, what features of work are characteristic for it. All deep pumps that are used today can be divided into centrifugal and vibration pumps, they can differ in other ways.