The downhole pump does not pump water well. Possible malfunctions of the trickle pump and methods for their elimination

The use of pumping equipment for lifting water from wells or draining a flooded room is the norm. Therefore, the purchase of submersible water units is quite common. But not always the unit is working properly. Unfortunately, improper operation of the device can lead to failure of the pumping mechanism (especially the pump "Kid", "trickle", etc.). We talk about how to repair a baby pump or a trickle at home without involving professionals, in our material.

The principle of reliable operation of the pump "Kid"

In order to understand how to repair a vibrating water pump with your own hands, a kid needs to know his device, understand the principle of operation of a vibration pump and its control. Knowing all the nuances of this "Baby", disassembling and assembling the pump with your own hands before and after the repair will be easy.

So, a water vibrator pump of the type "baby", "trickle", etc. works on the principle of creating vibrations in the aquatic environment. The fluid moved by the submersible water pump enters the hose attached to the pump and moves in a predetermined direction.

This vibrational movement is created using a vibrator built into the pump casing. The vibrator itself comes into a movable state as a result of exposure to an electromagnetic field. At the same time, we note that all work items and components are located in the aluminum case of the device. Outside, only the hose of the desired diameter is connected.

Important: the electromagnetic component of the pump mechanism is made in the form of the letter "P". There are also coils with copper wire winding. All elements of the electromagnetic component are also located inside the device body and are securely fixed by the compound. In this case, the resin serves to remove excess heat from the winding coils and protects it from contact with the metal of the casing.

Thus, the vibrator in the form of an anchor moves up and down in the pump casing, additionally fixed with a rubber spring. During the operation of the submersible pump "baby" or "trickle" the vibrator performs up to 50 vibrations per second, changing its position. Due to this movement, water mixed with air enters the mechanism through the valve of the unit and already exits through its nozzle, providing transportation of fluid through a hose or pipe. As a result, the pump pumps water well.

Types of malfunctions and solutions

If the pump is on, it makes noise but does not pump water

The cause of this failure may be the following:

- Loose fastening of bolts and nuts;

- Valve rupture due to wear;

- Gust of stock.

- In the first case, it is necessary to disassemble the pump casing and tighten all nuts to the stop. It is very important to tighten the upper fasteners well. This is done so that the nuts do not loosen further.

Important: if in the process of repairing the pump the baby or the trickle with your own hands you could not unscrew the coupling screws due to their rust, then you can simply cut them off with a grinder and install hex screws in their place. After such manipulations, the pump pumps water well over the entire diameter of the hose or pipe.

- In the case of a valve rupture, you will have to take steps to replace it with your own hands. The main thing here is to precisely observe the diameter of the working element.

- The cause of a stem rupture is the most complex. If the stem is broken or deformed, then its replacement is almost impossible.

If plugs are plugged and the cable is lit when the pump is turned on

Such a breakdown may indicate that the copper winding of the armature has burned out, or the pump cable is faulty. If the armature winding burns out, then when disassembling the pump, you will have to change it to a new one. If the problem is in the cable, then through the tester we confirm the failure and change the cable.

Important: not on all models of devices such as "trickle" or "baby" you can easily change the cable. Sometimes it is poured into the pump housing with a compound. In this case, you have to increase it by twisting.

Overheating of the working pump and increased vibration

As a cause of such malfunctions, the unit may idle. In this case, the rejection of the magnetic component of the pump will be apparent. To correct the situation, you have to disassemble the pump. The electrical component of the pump needs to be well tapped and heard. If the compound is separated, then it will rattle. It is necessary to remove it from the body and cut thin grooves with a mesh up to 2 mm deep on its surface. You can use a grinder. Notches must be formed inside the case. After this, the walls of the flask of the pump should be treated with glass sealant and mounted everything back.

Important: use only glass automotive sealant. A magnet and compound will have to be inserted under heavy weight (200-300 kg minimum). Otherwise, he simply will not return to his place. After drying, you can assemble the pump.

If the pump pumps, but very weakly

There may be insufficient gap between the vibrator. In this case, you have to add the right amount of washers. How much will be needed, determine by samples until the water pressure becomes optimal for you. Or de just try to tighten the nut tightly, as in paragraph 1.

Important: for any assembly / disassembly of water pumps such as a trickle or a kid, it is necessary to mark all the joints of the parts. So you can subsequently assemble the pump correctly.

Pressure switch failure

If you use a pressure switch for your submersible water pump, you will have to fine-tune it. Since it is the automation of this element that often causes the pumps of the trickle, baby, etc. to burn. So, if the automation of the pressure switch is set to the upper limit, then perhaps the amount of water supplied to the hydraulic tank will be exceeded for your needs. And this means that the pump will work with increased load.

In order to adjust the pressure switch for the periods of switching the pump on / off, you need to do the following:

- Carefully inspect the pressure switch and identify the scale with the values \u200b\u200b+ and -. They indicate an increase or decrease in the boundaries of the water in the tank. Relay parameters are set by adjusting special springs. Small is responsible for the pressure in the system. So, if you want the pump to turn on when the pressure drops to 1 atm and turn off at 3 atm, then you should completely release the spring.

- Further on the pressure switch we will regulate a large spring. To do this, turn on the pump and close all the taps. We wait until the “baby” or “trickle” pump turns off, and we monitor the pressure level on the manometer. If the upper limit is not equal to the desired 3 atmospheres, then you need to slightly tighten the nut on a larger spring. Do not make an effort. One turn is quite enough. After that, open the tap in the system and wait for the pump to turn on after the pressure drops. Then close the tap, wait for the pump to turn off and look again at the pressure gauge. So you can do it yourself do-it-yourself the pressure switch to the parameters you need and keep the pump working for water baby.

Important: the lower pressure limit is regulated in the same way on a smaller spring. Automation will operate within the pressure limits you set.

Video with repair of pumps for water "baby" and "trickle":

Submersible are very popular among owners of private houses and summer residents. pumping deviceswhose operating principle is based on the conversion of electromagnetic energy into electromagnetic oscillations, that is, reciprocating movements. The most popular model of vibration equipment is Rucheek, produced by the Russian plant Livgidromash OJSC.

Due to active use, the device sometimes malfunctions or works poorly. This problem in some cases requires the mandatory participation of a master, but most often you can do it yourself.

1 Device: design features and basic parameters

Vibration-type pumps have been used by humans since Soviet times. Their output today exceeds 1 million units per year, while the need for them has not yet been exhausted. Ease of use, reasonable price and stable quality - allow you to compete in the market of pumping equipment with units of foreign manufacture.

Despite the positive qualities and high technical characteristics, the repair of the Trickle pump is a frequent procedure that must be resorted to because of a breakdown. Before starting operations to restore the working condition, you should prepare a repair kit and other necessary tools, as well as understand the device and the principle of its operation.

1.1 Pump design

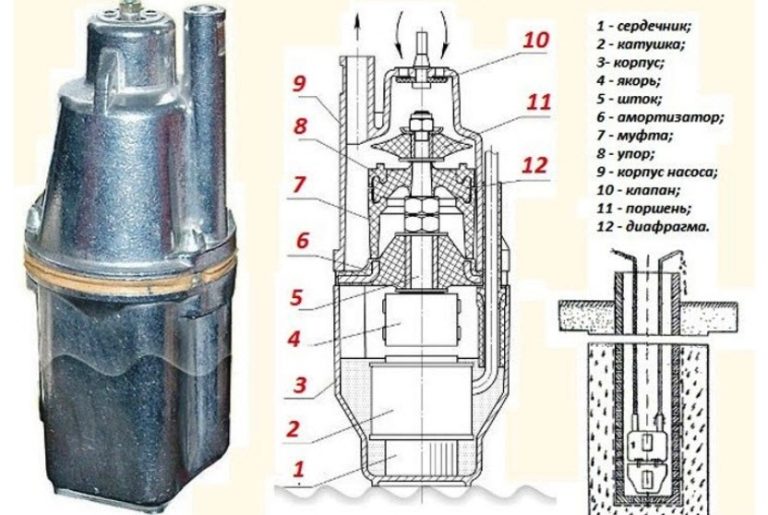

The vibration pump consists of the following elements:

- electromagnet;

- housing;

- vibrator;

- electric drive;

- clamp;

- screws, washers, nuts;

- sleeve;

- coupling.

The design of the Brook has a classic layout - the electric drive is located at the bottom, and the suction holes are at the top. This allows you to provide better cooling, to eliminate the intake of impurities from the bottom. The unit works without problems for a long time in a submersible state with suction openings open to the air.

An electromagnet located under the housing is formed from a winding and a U-shaped core, the material of which is steel electrical leaflets. The winding consists of 2 coils connected in series. The coil and winding are filled with a compound that provides insulation, heat removal from the coils and fastening.

The housing protects against mechanical damage, the valve installed in it, the role of which is to close the inlet openings. When there is no pressure, the fluid flows freely through a special gap with a diameter of 0.6 mm to 0.8.

An anchor and a rod pressed into it forms a vibrator. A shock absorber, a rubber spring, rigidly mounted on the shaft with two nuts, is placed on the rod.

Inside the shock absorber contains a sleeve that limits the compression of the rubber spring. The diaphragm, also made of rubber, is placed at a certain distance from the shock absorber. Its role is to create additional support for the rod and its direction. The diaphragm still separates the electric and hydraulic chambers from each other.

1.2 Pump parameters and its advantages

Most models indicate: nominal flow rate - 0.12 l / s and nominal flow rate - 40 m. The horizontal distance that the Brook can transport water is 100 m. Depending on the adjustment, the maximum flow rate without pressure varies in the range 1-1.5 cubic meters m per hour. The power consumed by the pump varies between 180-300 watts. The maximum current is 3.5 A, while the consumed current is practically not exceeded by the starting one.

The temperature of the pumped medium should not exceed 35 degrees Celsius. The pump is designed for operation with non-aggressive water, permissible pollution - 0.001%. To provide the unit with the required parameters, it is recommended to equip it with hoses, the inner diameter of which is 19 mm or more. The use of hoses with a smaller cross-section increases the likelihood of overload during pump operation, loss of performance, breakdown.

Among the advantages of the pump are:

- Consumer-oriented price. The cost of the hydraulic device for a long time remains affordable to the average buyer.

- Convenience of operation, mobility. The weight of the device, not exceeding 4 kg, contributes to its easy transportation and use in any tank.

- Ease of use. The hydraulic machine does not contain any electric motors, rotating elements, is not picky in maintenance, does not need preventive measures. Repairing a vibrating pump is not difficult.

- Profitability. To raise 1 cubic meter from a 10-meter depth, 0.2 kW of electricity is enough.

- Universality of application. The pump copes with the supply of water to the house, pumping liquid from flooded basements, sewers, watering summer cottages. It is used for deepening and cleaning wells. The resource of the device, of course, will decrease.

1.3 Principle of operation of the product

When connecting the unit to a power source with a network voltage of 50 Hz, the armature is attracted to the core. Every half period it is thrown back by the shock absorber. Thus, for 1 period of the current wave, the attraction of the armature occurs twice. Therefore, in 1 second it is attracted a hundred times. Frequent vibration of the piston located on the rod with the armature is also observed.

Due to the volume limited by the valve and the piston, a hydraulic chamber is formed. The actions in it spring due to the elasticity of the pumped medium containing dissolved air, and the oscillations of the piston. While water is pushed into the discharge pipe, and the spring is unclenched, compressed, the valve provides fluid inlet and through the suction holes - its outlet.

The trickle pump in the kit has a nylon cable used for securing and mounting it. The cable protects the consumer from electric shock in case of breakdown of insulation, as it does not conduct current.

2 Repair the pump Brook

Repair of the vibrating unit begins with extraction from the well. Submerge an unstable pump in a container of water. Plug in by checking voltage. If it corresponds to 200 V, turn off the pump, drain the water from it and blow out the outlet with your mouth. Proceed to disassemble.

Before this, it is recommended to mark on mating elements with a pencil or felt-tip pen, which will ensure the correct assembly and its efficiency. However, remember that if the warranty period of the device has not expired, it is forbidden to open the case yourself. In this case, be sure to contact the service center. Dismantling is carried out using a vice. They compress the ledges on the case, placed near the screws. Loosen the screws, as well as tighten, gradually.

When disassembling for the first time, it will not be superfluous to replace the screws with similar ones with a head for a convenient hexagon. These actions will further facilitate the assembly-disassembly of the device. To understand what we are dealing with, we suggest considering the most common causes of malfunctions.

2.1 Extraneous noises and sounds

The pump makes a distinctive ringing sound. After disassembly, perform a thorough visual inspection. If during the inspection an imprint of the anchor and a black spot are found on the surface of the electromagnet, this indicates that the anchor hits the surface of the magnet. This malfunction negatively affects the vibrator and leads to the combustion of the winding.

It is necessary to measure the distance from the fill cap to the surface of the magnet. The height of the fill should be 3.9 cm, but the value on the caliper should be 4.9 cm, since the thickness of the bar located on the surface of the fill is 1 cm.

Then the vibrator is disassembled, the adjusting washer is replaced in accordance with the norm of the filling height. For example, if it is 2.85 cm, then a washer of 1.05 cm is required. The large sleeve is inserted into the shock absorber, and the small one into the piston. After the pump is twisted, the screws are locked by punching.

Make sure that there is no skew, screw the screws evenly and tightly, without tightening too much so as not to shorten the gap between the armature and the magnet. Use measuring instruments to check pump parameters. In the absence of knocking, lifting height of at least 40 m - you managed to repair your unit successfully.

2.2 Pump is buzzing and pumping poorly

The brook shakes and buzzes poorly. This may be due to loose nuts or valve wear. In the first case, disassemble the pump, tighten the nuts all the way. The upper one needs to be fixed in order to avoid a similar problem in the future. If rust is found on the clamping screws in the process, use a grinder to cut them neatly, replace with new ones with a hex head. In the second case, just replace the valve, which is the stopper for the medical bottle.

2.3 Depressurization of the pump

The housing is in contact with the walls of the well, depressurization of the device is observed. As a result of impacts on the borehole walls, which are equivalent to hammer blows, the body does not withstand overloads, heats up, the fill exfoliates from the magnet. If the unit worked dry, similar phenomena will be observed. It is necessary to remove the magnet, before separating the electrical part, cut shallow grooves over the entire surface with a grinder. Then it is lubricated with sealant and returns to the housing in its place. It uses a press. Wait for the sealant to dry and assemble the pump.

2.4 Malfunctions related to power and pressure

When an insufficient amount of intake occurs in the vibrator, the problem should be fixed by adding washers to the vibrator. Their quantity is determined before the restoration of the necessary water pressure by experiment. If the plug is knocked out when connected, check the winding in the anchor. In this case, most likely, it burned out, and it needs to be updated.

When carbonizing a cable, a tester is needed to check for serviceability. It also requires replacement. It should be said that not all models have such a procedure available. In this case, the cable is increased by twisting.

When the rod (pumping mechanism) broke or its destruction occurred due to mechanical influences, repair is impractical. Consider buying an analogue.

2.5 FEATURES OF USE OF PUMPS OF HANDLES (VIDEO)

Summer residents use the inexpensive submersible pump "Trickle" for more than half a century. Due to active use, a structurally simple device sometimes turns out to be faulty or does not work satisfactorily. In some cases, it is impossible to do without the participation of repair technicians, and more often you can repair the Brook pump yourself. To do this, you need to understand the device and the principle of the pump, as well as stock up with a set of tools.

The electric pump "Rucheek", manufactured by the Russian company OAO Livhydromash, belongs to the class of household vibration devices. It is designed to supply water from wells and water wells with an internal diameter of at least 10 cm. It can be used for work in open water bodies, where it can transport water from a depth related to the interval of 1 - 40 m.

The maximum distance that the pump can transport water horizontally is 100 m. water intake point can be significantly removed from the consumer. The temperature of the pumped water is not more than + 35ºС. "Trickle" should not work in an aggressive environment and in water, including pollution greater than 0.001%.

Despite its small dimensions, the submersible pump copes with its functions perfectly, providing water supply over a long distance (click to enlarge)

Technical characteristics of the vibration pump "Trickle":

- supply voltage - 220V;

- power - 3.4 W;

- maximum immersion depth - 3 m (with a low-production well, an increase in immersion depth up to 5 m is allowed);

- working pressure range - from 4 to 60 m;

- dimensions - 250x99 mm, weight - approximately 3.5 kg (depending on version).

The pump is equipped with a power cord from 10 to 40 m and a nylon cable for hanging the unit when installed in a well or well.

As an equipment for pumping contaminated water, the Trickle pump can be used provided that no more than 0.01% is turned on and the parts are cleaned regularly (click to enlarge)

Of course, such a small pump will not be able to provide water to the entire country house with a large number of water consumers. "Trickle" successfully serves to perform tasks such as:

- Water supply of a small country house with 1-2 points of water consumption.

- Water supply for the bath, watering the garden.

- Temporary replacement of the main pump in case of failure.

- In slowly filled water sources with a small flow rate;

- The first or periodic cleaning of the well;

- Filling the heating system.

Pump performance directly depends on the depth of the water source: the deeper it is, the higher the productivity of the unit.

Device and principle of operation

The submersible pump "Trickle" consists of the following parts: electric drive, vibrator and housing, which are interconnected by four screws. The electric drive of the unit includes a core with two coils and a power cord. The vibrator consists of a shock absorber, a diaphragm, an emphasis, a coupling and a rod. An anchor is pressed into the bottom of the stem; a piston is attached to it at the top.

The pump casing is a casing, in the upper part of which there is a glass with holes for water inlet and a pipe that provides water outlet. The existing valve serves to open / close the inlet openings.

The pump pumps water through vibrations of the piston and armature. They are driven by an elastic shock absorber, which turns the alternating current received from the network into a uniform mechanical vibration. The stem transmits the movement to the piston, which when vibrated creates a mini-hydraulic shock in the glass with holes. The valve closes at this moment, and the water is pushed into the outlet pipe.

There are no rotating elements in the pump design, which reduces the risk of breakdown, as friction is the main cause of the malfunction (click to enlarge)

Due to the fact that water intake takes place in the upper part of the unit, the system is cooled and it does not heat up during operation. Another advantage of the intake located on top is that the sludge from the bottom is not sucked in by the working body. As a result, the unit is much less likely to have a lower fence clogged with a muddy suspension, due to which the pump should be periodically disassembled and cleaned.

Setting the submersible pump "Trickle"

The trickle pump is considered reliable equipment. With proper operation and timely maintenance it breaks rarely. In some cases, troubleshooting can be done by adjusting the pump. To do this, first of all, an idle or unstable pump must be removed from the well (well) and suspended without a hose in a container of water. Next, you need to connect the device to the network and check the voltage, it should be at least 200V.

If the voltage in the network corresponds to the norm, then turn off the pump, drain water from it and blow out the outlet. Purging can be done by mouth without using any special tools.

A correctly tuned trickle pump is blown without any problems, and if you blow it harder, you can feel the piston stroke inside. Air must also travel in the opposite direction. If this does not happen, then it is necessary to configure two parameters of the unit, having previously disassembled it.

Dismantling the domestic pump "Trickle" is carried out using a vise, which compresses the ledges on the body, located next to the screws. The screws must be loosened gradually, in turn. At the first disassembly, it will not be out of place to replace the screws with similar screws with a head for a convenient hexagon, this will greatly facilitate assembly and disassembly during the next repair.

From the principle of operation of the pump "Trickle" described above, it follows that the two parameters are configured in the following order:

- Setting the position of the piston. It should be parallel to the rest of the unit. The parallelism control is carried out using a caliper. Misalignment of the piston body can occur due to the gap between its metal sleeve and stem. To eliminate it, you need to wind the rod with foil until full parallelism is observed.

- Checking the coincidence of the axis of the rod and piston. When they are displaced, the inlet glass usually “fidgets” along the gasket. To eliminate it, it is necessary to disassemble and reassemble the assembly, temporarily securing the glass during assembly to the laying with adhesive tape pieces.

- Setting distance between piston and seat. It should be approximately 0.5 mm. Adjustment is made by changing the number of washers with a thickness of 0.5 mm, mounted on the rod. This indentation is necessary so that air during purging, and subsequently water, passes into the outlet pipe without obstruction, and when pressure increases, the outlet is blocked by a piston.

With an increase in the number of washers, the piston approaches the seat, therefore, when the mouth is purged, air will not pass. Only with suction in both cases should air circulate freely.

It happens that the piston rod turns out to be bent. Fix it is unlikely to succeed. However, if this did not affect the operation of the unit, you can slightly correct the position by turning the gasket 180º relative to the rod.

A properly configured and assembled vibration pump without a hose when immersed in a container with water should give a pressure of 0.2-0.3 m and work without interruption at normal voltage in the mains 220V plus / minus 10V. If, after adjustment, the equipment does not work or does not work satisfactorily, it is necessary to establish the cause of the breakdown and eliminate it.

After assembly, it is necessary to tighten the screws gradually and in order to avoid skewing the case; it is better to do this with an assistant

Causes of malfunctions and their elimination

Please note: if your pump is under warranty or after-sales service, it is not possible to independently open the case and repair work! In this case, you should contact the service center or the seller of the equipment.

Consider the most common breakdowns of the "Rucheyk" domestic pump that are not associated with factory defects and occur during operation.

Image Gallery

Replacing worn and torn valve

The ingress of small stones and other foreign bodies often occurs when using a pump to pump drainage water from the basement, to clean the well, etc. To avoid this, it is necessary to install an additional fine mesh filter, which is pulled onto the water intake part of the pump, where water is sucked in.

If a foreign body gets inside the mechanism, then most likely it will go through the built-in filter and get stuck at the valve, as the valve is made of waterproof rubber, then after a while it will break. A sign of rupture or excessive valve wear is a significant and increasing decrease in performance. Pump humming when a valve is damaged usually remains normal.

In this case, it is not difficult to repair the pump; it is enough to replace the rubber valve, having previously disassembled the pump. Some users claim that instead of a faulty valve, you can use a cork from a medical bottle. This is not recommended, as this design will not last long, it is best to use a special repair kit for the vibration pump.

Exfoliating Electromagnet Fill

Electromagnet separation occurs when a running pump comes into contact with the walls of a well, well, or water tank. Such strokes will be synchronous, and their number exceeds 100 beats per minute. The body of the unit does not withstand such a load and begins to heat up, which leads to delamination of the fill from the electromagnet (core). The same thing happens if the pump runs dry for more than 5 seconds without water.

A sign of detachment of the magnetic part is overheating of the pump and excessively intense vibration. To resolve this problem, the following steps must be taken:

- Turn off the pump and raise it to the surface.

- To disassemble, separating the electrical part and get the electromagnet with coils. To do this, use a grinder to cut shallow 1-2 mm grooves around the magnet

- Cut through several similar grooves on the inside of the housing.

- Lubricate the element with glue, then with sealant, which is used for auto glass.

- Mount the electromagnetic part in the housing and wait until it solidifies.

Reassembling the pump is permitted only after the adhesive has completely hardened.

Prevention of depressurization of the housing

Depressurization of the housing leads to noticeable interruptions in the supply of water. To prevent it, you must correctly select the dimensions of the pump for a particular well or well. The unit must not come into contact with the walls during operation.

Diagnosing "Symptoms"

Do not let the pump run dry! It is also required to regularly conduct routine inspections of the well, in the event of friction against the walls, it is necessary to immediately raise the pump to the surface and eliminate the cause of friction by moving the pump.

To protect the pump housing from mechanical damage, it is necessary to use a special rubber ring worn before suspending the pump in a well or well

Reason # 1: The pump buzzes and does not pump

This is the most common complaint of the owners of the Brook pumps: the unit is buzzing, but it does not pump water and the case does not heat up. The causes of the malfunction can be several:

- Loose piston fasteners. This is due to vibration and, in principle, is inevitable after 2-3 years of operation. The use of additional washers will help extend the life of the mount. Repair in this case consists in tightening the piston nut or replacing it.

- Valve damage. To fix the problem, it is necessary to disassemble the pump and inspect the valve. It can be deformed or torn by fine gravel or grains of sand falling into the pump. In this case, replacing the rubber valve with a new one will also help, but this replacement will have to be done regularly once every 1-2 years, depending on the intensity of the pump.

- Rubber piston wear. You can determine by reducing the volume of pumped water, accompanied by increased buzz of the pump. It is treated by replacing a damaged flexible part.

- Poor shock absorber mount. With this breakdown, the shock absorber does not fulfill its function, the rod hangs and the anchor knocks on the electromagnet. Repair - tightening and / or replacing shock absorber nuts.

- Broken or broken stem. Occurs due to intense mechanical stress. This is the most difficult case of failure. Repair consists in the complete replacement of a non-working part. In this case, it would be advisable to consider the option of buying a new domestic pump.

If you find that your "Trickle" is buzzing, but does not pump water, you must immediately disconnect it from the mains, raise it to the surface and look for the cause of the malfunction. In this case, the pump must not be left running!

If the fastening screws do not loosen, then they must be cut off with a grinder and replaced with new ones during assembly, the same applies to the internal nuts and fastening screws

Reason # 2: The pump heats up and buzzes a lot

This malfunction is most often associated with the fact that the equipment worked without immersion in water. The vibration pump has a design in which all of its elements are cooled due to the fluid pumped by it.

If the water level drops or is absent, the unit stops cooling and overheats. Most often, in such conditions, the electromagnetic part fails: the winding of the electromagnet burns out and it completely loses its properties, which means it does not provide vibration.

It is difficult, but possible, to repair the electromagnet independently. For repair you will need the following tools and materials:

- copper wire for winding with a diameter of 65 microns;

- pVC tube with a diameter of 4 mm;

- rapid hardening epoxy;

- soldering iron and electric stove;

- winding machine;

- hammer, flat screwdriver;

- protective equipment: mask of the welder and mittens.

Repair work involving the use of a soldering iron and epoxy is best done in the open air. In no case do not inhale the fumes of the resin, they are toxic and have a very negative effect on the lungs! Work must be done with gloves, avoiding contact with the skin. When repairing the electromagnetic part of the pump, an assistant who can hold the pump in his hands when removing the electromagnet from the coils will not be out of place.

When working with a soldering iron, you must observe the following precautions: do not allow sparks and heated elements to get on the rubber parts of the pump

Step-by-step repair instructions for the electromagnet of the submersible pump "Trickle":

- We disassemble the pump and remove the electromagnet with coils by heating the casing with an electric stove. The epoxy resin surrounding the electromagnet will become soft under the influence of temperature and the element can be easily reached by gently tapping the unit on a wooden deck.

- Until the epoxy has solidified, it is necessary to clean the inside of the pump from its remnants.

- We remove the electromagnet from the coils with a wooden block and a hammer. The assistant must hold the electromagnet in his hands, and you point the bar to the electromagnet and carefully knock it out, striking with a hammer on the bar. Why is an element necessary to keep? This will prevent split coils, as it is possible to better control the force of impact.

- We unwind the burned windings of the coils and clean the surviving parts of the remnants of the epoxy substance.

- Using a winding machine, wind the reel to get 8-10 layers, and fix the last layer with cotton tape. At the beginning of the winding, put on a PVC tube, and fix the coil frames on the core of the electromagnet. Strip the ends of the windings that are on the outside and solder with a soldering iron to obtain the desired connection. Bite off the excess winding.

- Route the cable into the pump housing through the seal to the place where the electromagnet will be installed. Cut the end of the cable into separate wiring and strip their ends. Twist the ends of the cable with the beginning of the windings of the electromagnet and coils and solder. Lower the electromagnet with coils into place, while removing excess cable. For a reliable landing of the electromagnet, use a hammer, delivering them accurate point blows through a wooden block.

- Clamp the body of the unit and align it using the building level. Stir the epoxy resin and fill it around the coil to the top edge of the electromagnet. We wait 10-15 minutes for the epoxy to fill all the voids. It takes at least 24 hours to harden the resin. After this time, assemble the pump and try its work, immersing in a container of water.

Note that repairing an electromagnet is a time-consuming process. In most cases, it is more advisable to purchase a new pump "Trickle", but if you have the time and desire, you can try to do it yourself in accordance with the step-by-step instructions.

Reason # 3: The pump runs silently

A trickle is not a pump that works silently in good condition, so the lack of measured buzz should alert you no less than excessive noise. When the noise level is reduced, the pressure of the supplied water is always noticeably reduced. The reason for this malfunction is that the voltage in the mains has dropped below the minimum allowable limit, i.e. below 180V. With a voltage reduction of 10%, the pump performance decreases by 50%.

In this case, the pump must be disconnected from the power supply and measures must be taken to set the voltage to normal, for example, use a special stabilizer.

If the voltage in the mains is too high, the "Streamlet" pump does not turn on, because protection is triggered.

How to avoid pump breakdown?

- Do not allow the pump to run without water.

- Do not use the pump if there is an unstable voltage in the mains.

- Do not operate the pump with a damaged power cord or housing.

- Do not move the unit by the power cord.

- Do not pinch the hose to increase pressure.

- Do not pump water with dirt, impurities, garbage.

When installing the pump in the well, it is necessary to wear a protective ring made of rubber on it, which will protect the equipment from impacts on the walls.

Switching the unit on / off can only be done with a plug or a bipolar switch embedded in a fixed wiring system.

Before use, carefully read the operating instructions and follow the manufacturer's recommendations, this will help to avoid damage

During operation of the vibration pump "Trickle" it is necessary to timely conduct a preventive inspection and monitor the quality of the pumped water. If the water comes in dirty, then the pump must be turned off and its position relative to the bottom checked.

Video about the repair of the pump "Trickle"

Repair of the pump "Cricket" - a complete analogue of "Brook":

Features of repair and use:

Electric pump "Trickle" - a simple and reliable unit. In the event of a breakdown, it can be repaired with your own hands, significantly saving on repairs. But the best option is to prevent the pump from failing. It is not difficult to do this, it is necessary to carefully study the operating instructions and carry out timely maintenance and monitoring of equipment operation.

Vibration pumps have firmly occupied their niche in the market due to their low cost, simplicity of design, and unpretentiousness in operation. In everyday life, they are more often used for household needs when taking water from wells and open reservoirs in small volumes for a relatively short time.

Fig. 1 Submersible pump Kid, Brook, Aquarius, Bison - appearance

Principle of operation and design of the vibration pump

Vibration pumps with a small weight of about 3 kilograms and energy consumption of up to 300 watts are capable of pumping water volumes of a maximum of 1.5 cubic meters per hour with a pressure of up to 60 m. The standard model of a water pump pump has a nominal head value of about 40 m. And a capacity for pumping liquid 0.43 m3 / h

The market offers a wide range of vibration pumps of domestic production, Chinese counterparts and the CIS countries, which have exactly the same design.

Fig. 2 Design of vibration pumps

The main element of the vibration pump is a U-shaped electromagnetic coil 10 with an anchor 8, on the rod 3 of which an elastic piston 2 is fixed. The coil is separated from the working chamber by a diaphragm 5, mounted in the seat 6 - this prevents the penetration of water into the electrical part of the pump with an electromagnet and cable 11 . During the return movement of the armature with the piston, the fluid is drawn by the electric pump through the inlet with the check valve 1 in one half of the housing 4. The translational movement of the piston closes the check valve and pushes water out Res outlet with hose attached thereto 13. In the second half of the pump casing 9 has a bracket 12 for attachment to a cable, the power cable is typically connected to drain hose 14 by means of ties.

The pump vibrates at a frequency of 6,000 times per minute during operation, so the devices are called vibrational.

Fig. 3 Disassembled Vibration Pump - Pump Accessories

Why the humming vibration pump does not pump water

Often, the reason for the failure of a working vibration pump is associated with its principle of action - constant vibration, leading to unwinding and loosening of the body fasteners and internal parts of the mechanism. Other malfunctions are more serious and require other troubleshooting approaches.

Failures due to malfunctioning parts

The body of a standard vibration pump consists of two halves, which are usually fastened with four bolts. When they are weakened, the separation of the two parts occurs, leading to a change in the working clearances and water getting into the working chamber - as a result, the engine will buzz and work, but water will not be supplied.

Sometimes bolt loosening can lead to a complete untwisting of the housing fastening and an irretrievable loss of the second half of the pump in a deep reservoir or well. One way to avoid this situation is to lower the electric pump into the source of water in a bucket or other container with holes, and this also reduces the harmful effect of vibrations on the walls of the source.

Another malfunction may be the unwinding of the fasteners of the non-return valve and the piston - while the pump is working, but it does not pump water well.

![]()

Fig 4. Dismantling the pump with your own hands with the installation of a coil

Pollution

Models of vibrational pumps with a lower water intake are most exposed to the risk of clogging of the working mechanism with dirt, sludge and small stones - all this can lead to a lack of water supply when the electric pump is running.

Parts damage

The use of a vibrating dirty water pump will result in wear on the rubber parts of the reverse valve and piston. In this case, the piston will not be able to draw fluid into the housing in the required volume, and the check valve will release it back, this will lead to a low pressure or a complete lack of water supply. The pump can be repaired with a simple replacement of components.

Fig. 6 Repair of the submersible pump with a do-it-yourself kid - typical malfunctions during disassembly

- stock breakage;

- valve failure;

- loss of a check valve mounting bolt;

- burnout of the winding.

Coil peeling

One of the malfunctions may be the lack of movement of the piston due to a violation of the epoxy insulation of the electromagnet, the reasons being the different linear deformation of the metal casing and filling during heating. In this case, the coil exfoliates and moves freely inside. Before disassembling the pump, you can determine the malfunction by tapping the casing with a hammer - the sound analysis will tell about the violation of the integrity of the structure. Do-it-yourself vibration repair of the Kid pump is to remove the coil from the pump, apply a notch to the inside of the casing, and install the electromagnet in place under pressure. Filling the free space with gluing the coil can be done using epoxy resin or a particularly durable glass sealant.

Short circuit

Vibration pumps are mainly operated without float switches, pressure switches and dry run, many models are not protected against overheating and are designed with a lower water intake - all this makes them more prone to burnout compared to other types.

When working without water, the winding overheats, burns out the insulation and interturn circuit of the copper wire - the vibration pump buzzes but does not pump water. In this case, plugs are knocked out, the electric cable is very hot or charred. It is possible to fix the malfunction only by rewinding the winding, which is economically disadvantageous and ineffective in terms of quality.

Failures of vibration pumps, due to the simplicity of their design, are quite easily eliminated with their own hands in most cases. Before disassembling the pumps, you should have a grinder to cut off the rusty external housing mounting bolts. In order to avoid non-repairable burnout of the electric pump winding, it is better to purchase devices with an upper water intake and protection against overheating.

DIY vibration repair of a submersible pump of the type Kid, Aquarius, Trickle, Neptune, Chestnut

At gardeners and gardeners immersion vibrations are very popular kid pumps, and other modifications that work on the same principle. They are inexpensive, productive, create quite a lot of pressure and have great pumpability (i.e. they can supply water over a sufficiently large distance). But, unfortunately, these pumps are not very reliable. Moreover, their damage is very diverse. Where the valves leak, where the rod breaks, problems with the pump winding, power magnet, short circuit or open circuit. There are quite a few simple faults that can be easily fixed, but after repair, for example replacing rubber valves, the pump does not pump or pump very weakly. Here you still need to correctly adjust and assemble the pump. To understand how to properly adjust the pump, we consider the principle of operation and the important points of proper adjustment.

Principle of Operation and Design

Vibrating submersible pumps relate to inertial type pumps. The work of inertial pumps is based on the excitation of oscillatory processes in a liquid that contribute to its movement.

All vibratory pump designs same type. The pump consists of an electromagnet, a vibrator and a pump housing.

The electromagnet consists of a U-shaped core assembled from sheet electrical steel and two coils wound in an enameled copper wire.

The core with coils is installed in the body and filled with epoxy compound. The compound is used to secure the core with coils in the housing, serves as an insulating material and provides heat removal from the coils to the housing through which they are cooled.

The compound is made of epoxy resin, plasticizer, hardener and quartz sand, which improves thermal conductivity.

The vibrator consists of an anchor with a rod pressed into it. A rubber spring called a shock absorber is installed on the stem. The pump parameters and its efficiency depend on the quality of manufacture of the shock absorber.

In the design of "Brook" and "Baby" shock absorbers are used only from natural rubber, which has been vulcanized for a long time. This ensures stable pump parameters.

A rubber diaphragm mounted at an appropriate distance from the shock absorber through a remote clutch serves as an additional support for the rod and provides its direction. The diaphragm also separates the pressurized electric and hydraulic chambers. The emphasis provides compression and fixing of a diaphragm in the pump case.

A rubber piston is attached to the end of the stem.

And finally, the last node is a pump housing with a valve installed in it, blocking the inlet openings. Between the valve and the body there is also a gap of 0.6-0.8 mm, which ensures free flow of fluid in the absence of pressure.

The valve is also made of high quality rubber. It is the most vulnerable element in the pump and first of all fails.

Vibrating pumpgreat for irrigation systems, the construction of which was discussed earlier.

How does a vibration pump work?

When you turn on the pump in an electrical network with a current frequency of 50 Hz, the armature is attracted to the magnet. With the magnetization reversal of the poles, every half period the shock absorber drops the anchor back. That is, for one period of the current wave, for those who know electrical engineering, the anchor is attracted 2 times. Accordingly, per second at a frequency of 50 Hz, the armature is attracted 100 times. At the same frequency, the piston vibrates on the same rod as the armature.

The volume in the pump housing, limited by the piston and valve, forms a hydraulic chamber. Since the water pumped by the pumps is a two-component mixture containing dissolved and undissolved air, it has some elasticity - it spring during mechanical stress, which happens in the hydraulic chamber when the piston oscillates.

Water as a spring is compressed and unclenched and its excess is pushed into the discharge pipe - thus the pump pumps water. At the same time, the valve provides water inlet and restricts the water outlet through the suction openings.

Pump Modifications

Pump "Trickle" produced by Livhydromash OJSC has a classic layout, i.e. the suction openings are located on the top, and the electric drive is located on the bottom. This design has better cooling, eliminates the capture of impurities from the bottom. The pump can work for a long time in a submerged state with suction openings open to the air.

In this condition, according to international standards, the pump must run for 7 hours. Pumps with top suction openings can withstand such tests.

In critical cases, it is still worthwhile to purchase pumps with a thermal relay, which will turn off the pump when it overheats. Overheating can occur in a limited volume or when the voltage rises above the permissible level. A pump with a thermal relay will cost more.

Bavlensky plant "Electric motor" satisfying the demand of discriminating consumers, mastered the release pumps "Baby" in several versions:

- “Baby” and “Baby K” - with the lower location of the suction openings (K- with thermal relay);

- "Baby M" - with the upper arrangement of suction openings;

- “Kid-3” - allows for use in 3-inch wells, i.e. wells equipped with casing with an inner diameter of 80 mm.

It is advisable to purchase pumps with a lower arrangement of suction openings with a thermal relay. Otherwise, they must not be left unattended. The prevailing opinion about the advantage of pumps with a lower water intake is that they can pump water from a shallow reservoir - debatable. The pump with the upper water intake can be positioned horizontally and it will work perfectly.

The pumps are necessarily equipped with a nylon cable for mounting and securing the pump. The nylon cable is not conductive and excludes electric shock in the event of an insulation breakdown. The use of a steel cable for fixing leads to grinding of the eyes in the pump casing.

Although domestic pumps are manufactured according to the II class of protection against electric shock (- the sign of the II class) and the insulation strength is checked with a voltage of 3750 V - it is better not to touch the electric pump connected to the network and not to experience fate.

If the wiring is equipped with grounding, it is better to purchase pumps according to protection class 1, i.e. with euro plug. But such pumps are also more expensive.

PAY ATTENTION to fakes when the pump is equipped with a Euro plug, and the wire is two-core, and even with a cross section of 2x0.5mm, instead of the minimum allowed by the international standard 2x0.75 mm.

Do not equip pumps with hoses with an internal passage of less than 19 mm (3 / 4). This leads to pump overload and loss of performance.

Pump parameters

Pump parameters

Information on the parameters of the vibration pumps of different manufacturers, indicated on the plates and in the advertisement, is very contradictory.

On most domestic pumps, a nominal head of 40 m is marked with a nominal flow of -0.12 l / s (or 0.43 m3 / h).

On imported (Chinese) pumps, the maximum head is marked from 60 to 80 m. This is the head with a completely blocked flow. In fact, all these pumps with a pressure of 40 m pump much less than the pumps "Trickle" or "Kid".

The maximum flow rate determined during operation of the vibration pumps without pressure, depending on the adjustment, ranges from 1 to 1.5 m3 / h.

The power consumed by the pumps is indicated in the range from 180 to 300 watts. In fact, the pumps adjusted to the rated parameters consume power from 190 to 220 W in the head range from 1 to 40 m. With an increase in voltage, productivity, current and power increase. By reducing the voltage to 200 V, the performance decreases by 25%. Thus, vibration pumps can operate with voltage fluctuations inherent in rural areas and suburban areas.

The immersion depth indicated in the marking means at what level a pump can be submerged under a layer of water, in this case 3 m.

Although the pump shell withstands significantly greater pressure, we stopped at 3 meters. For the Bawlenian "Kids" and the Lebanese "Brooks" this is enough. If the pump drown deeper (up to 5-7 meters) - there will be no problems.