Automation for submersible pumps. Well pumps - where and which are used. Video tutorial: setting the pressure switch for a submersible pump

In terms of functionality, a summer cottage or a country house should be no worse than a city apartment for amenities. In order to quickly and independently do without any help (specialists) to equip the automation of the pumps, you need to work hard.

The most difficult task in a country house or cottage is to create a decentralized water supply. But if the water supply system is ready and capable of working, all that remains is to make a working mechanism so that the system for the submersible pump works correctly and automatically quickly.

1 Types and differences of submersible pumps

Before understanding automation, we must understand with you what types of pumps exist. There are only two species in the world submersible pumps:

- Vibrating.

We all know that the above types of automatic submersible pumps are installed only in the water that these pumps pump.

That's why it is called "submersible". Most of the summer residents, and lovers of country houses believe that, much better than the surface, but this can be argued.

In principle, the operation of these pumps is the same for them, but the mechanism itself is different from each other. It should also be noted that their working conditions are also different. Submersible pumps can be used in wells of any depth; they need to increase the pressure of water in order to pump the input upward. It should be noted that submersible pumps operate at a depth of up to 10 meters in the well.

If you have a well more than ten meters long, then highly specialized pumping systems are used to pump water from the depths.

It should be noted that surface models of pumps cannot pump water from a well more than ten meterss.

For greater depths, it is best to use vibration pumps, which are most often used in water wells. But the centrifugal pump is most often used in the agricultural sector, where water supply is used.

The main element in the vibrating device is the membrane. When the mechanism vibrates, the membrane is deformed. As a result of this, a pressure difference occurs in the system. As a result, we get the effect of pumping liquid in the direction you need.

According to this principle, the following types of pumps work as:

- Aquarius.

- Gardena.

Before buying the above pumps, make sure they have a thermal switch. Also, when buying, you need to check the operation of the water intake at the bottom of the pump. If the soil is heavy at your summer cottage or country house, then it is advisable to install a vibration device as low as possible.

This is done so that the well (the walls of the well) does not collapse, and also that the vibrating device installed in the ground is not contaminated with different objects. It is also advisable to install vibration models only in fortified sources. But the pumps of the brand Aquarius, Gardena or the Kid are easy to install and dismantle.

You can make repairs quickly with your own hands. If we decide to consider the working mechanism of a centrifugal pump, then you can immediately see that special wheels are attached to it to the shaft, which is only one. Here you can see that the difference in pressure produces the rotation of the blades on the wheels. As a result of this, fluid is pumped in the direction you need. The most popular models in the CIS are centrifugal pumps.

There are several reasons for this. The models are stable and have gained considerable versatility in use. Also, such pumps - models can be connected with your own hands and you will not spend on it. And this saves the cost of arranging water supply.

2 What types of automation are there for submersible pumps?

Today, there are three main types of automation for submersible pump models, and these are:

- The control panel of the pump and to it the control unit.

- Press control.

- A mechanism with a control unit that maintains a stable water pressure throughout the system.

If we consider the first option, we will see that it protects the pump from various voltage drops and short circuits, which can also happen.

In order for you to have everything on automation, you must first connect the automation unit to a pressure switch or to a level switch. Also, in some cases, for automatic operation, the system can be connected to a float switch. But here it is the price. This automation unit costs at least 4000-5000 rubles.

But here it is necessary to take into account the fact that, without a pressure switch, the automation unit will not work. There is also a need for special protection of the pump against dry running. In this case, there is a waste of money that will exceed 5,000 rubles and even higher. It is best to select blocks with the built-in systems listed above.

Aquarius 4000 already has such a system. In this block, if you do the installation yourself, everything is very simple and does not require the knowledge of a special specialist. The second option includes “press control”, which has an integrated system and also has protection against dry running. You can control such a device in advance, and it includes taking into account the level of water pressure, and also necessarily takes into account the water flow.

Now you must monitor the water flow in the device, if it exceeds the mark of 50 l / min, then this device works as normal, that is, in press-control mode. If there is a reduction in water flow, or you notice that the pressure is increasing, then in this case the press control must turn on the pump, and this is protection against dry running.

2.1 We connect the electronic unit for automation for submersible pumps.

If the flow rate of the system in the system increases, and it does not exceed the mark of 50 l / min, then the system starts up when the pressure in the entire system decreases, and this is approximately 1.5 atmospheres.

Such a function is most important for conditions of a sharp increase in pressure, where it is necessary to reduce the number of shutdowns and turns on the pump with minimal water flow. And this very well affects the operation of the accumulator.

The principle of all this is a sharp and powerful increase in the pressure of the water pressure in the pump, and can even reach 10 atmospheres. Here, the automatic shutdown of the pump or automation is immediately triggered.

An example is a press-control device such a pump model as "BRIO-2000M". Its price can please you, it does not exceed 5000 rubles. Also here can be attributed a pump brand Aquarius, their price is also from 4000 rubles. The hydraulic accumulator which belongs to the reservoir for the Aquarius and BRIO pumps costs at least 4000 rubles. If you decide to purchase this type of automation and install it yourself, it will be somewhat more complicated than the previous version.

Another automation option is the control unit. It consists of a mechanism that maintains stable water pressure throughout the system. This mechanism is acceptable where it is impossible in no case to allow a sharp increase in pressure. And all this is necessary if, for example, energy consumption sharply increases, and the efficiency of the pump decreases. The above can happen if the pressure rises.

It happens that there is a sharp increase in pressure and there are interruptions in the constant pumping of water, and this happens due to the rotation of the rotor of the pump motor.

The most common control units of these types can be pumps of the brand Aquarius and Grundfos. Pumps "Aquarius" are popular not only in the CIS countries, but throughout Europe. Since installing these pumps with your own hands will not be difficult. They are also cheap compared to other units.

Such control units cost from 4,500 rubles. The most expensive unit can reach from 10,000 rubles and above. Prices depend on the model, which can go on their own, but there are models that are equipped with different bells and whistles, mechanisms and mini systems.

Attract consumers to purchase automation for pumps, their ease of installation. You can install automation for pumps yourself.

Not everyone knows that automation for pumps needs an electronic kit. Also, for vibrating pumping systems, it is necessary to additionally install expensive equipment.

And for centrifugal pumps you can only install a conventional tank, which is equipped with electrical contacts.

It should also be noted that any submersible pump will only function properly in clean water.

If, for example, water with impurities, then the ingress of such water into the pump blades, will lead the automation system for pumps to be unsuitable. And this must be clearly taken into account.

2.3 Automation for a submersible pump - video review

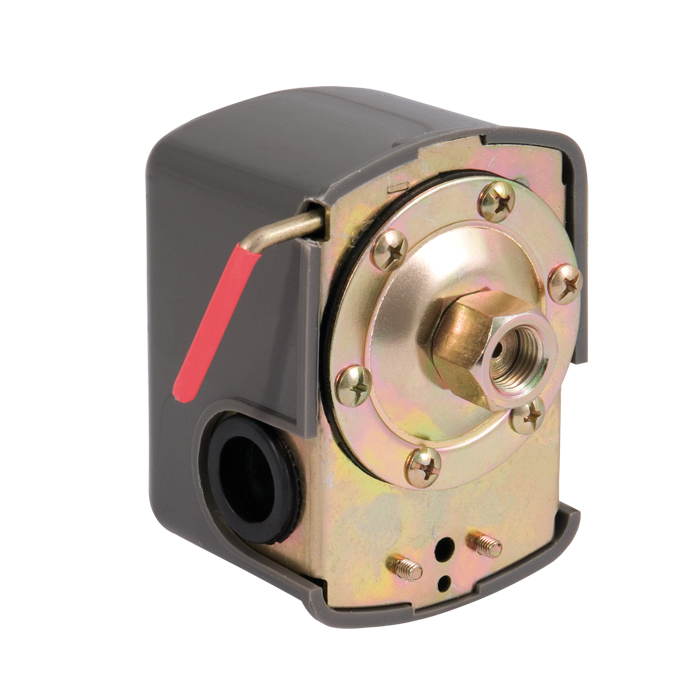

The autonomous water supply system of a country house or summer cottage consists of various mechanisms, sensors and equipment. However, the effective operation of this system largely depends on the fluid pressure switch for pumping equipment. For its effective operation, it is necessary to correctly install, configure and operate the product. To install and configure this unit, you will need a connection diagram for the pressure switch, as well as knowledge of the principles of operation of such equipment. Also, thanks to this, you can appreciate the importance of the correct operation of the device and the need for its use in the autonomous water supply system of a country house, cottage or cottage. The video at the end of the article will help you better understand the intricacies of using relays.

Appointment of the device

Some pumping stations are not equipped with automatic devices for monitoring and adjusting the operation of the pump. However, for the water supply system to operate in stand-alone mode, it is necessary that the start and stop of the pumping equipment occur automatically, because the implementation of these actions manually requires constant monitoring of the system, which will not allow you to do your business.

Optimal control over the operation of the pumping station will provide a relay. This device is made in the form of a control unit in a plastic case. Two springs are installed inside it, which regulate the upper and lower pressure limits in the parameters for switching the pump off and on.

The relay is connected to the accumulator - storage tank with air and water in a rubber pear. Since the rubber bulb with water is inside the cavity with air, the walls of the bulb act as a membrane. In working condition, the water in the pear stretches the walls of the membrane and presses on the air in the chamber, which creates a certain pressure. When water is consumed, the volume of the pear decreases, and the air pressure in the chamber also decreases. At the moment of reaching a certain pressure set on the relay, a sensor is triggered, which leads to the closure of the contacts and the start of the pump. The accumulation of water in the tank occurs until the pressure rises to the maximum set on the relay. As a result, the contacts open and the pump turns off.

Important: in order to properly connect the relay, it is necessary to connect the equipment to the water supply system of the house, to the pump and to provide power supply.

Design features and principle of operation

The design of the relay is made in the form of a compact unit with springs, which through the nut allows you to adjust the minimum and maximum pressure. A membrane is connected to the springs, which reacts to its differences and closes or opens the electrical circuit, which causes the pumping equipment to start or stop. The principle of operation looks like this:

- When the pressure drops to the set minimum, the spring pressure on the membrane weakens and the contacts close, which leads to the start and pumping of water into the system.

- If it is increased to the set maximum, the compression of the spring increases, which leads to the opening of the contacts and the stop of the pump.

If the relay is used in conjunction with a pumping station, the principle of operation looks like this:

- First, the pumping equipment draws water into the hydraulic tank.

- As the rubber bulb is filled, the air pressure in the tank increases. In this case, the information is fed to the pressure gauge.

- When the pressure in the accumulator rises to the upper limit set on the relay, the device opens the contacts, which leads to shutdown of the pumping equipment and the cessation of water injection.

- Over time, the water from the tank is consumed by the consumer, and the air pressure gradually decreases. When it reaches the minimum set on the relay, the relay is activated and closes the contact, which leads to the start of pumping equipment and the accumulation of water in the tank.

- After that, the cycle repeats.

Thanks to the use of a relay in the water supply system, it is possible to maintain a constant pressure and the pressure of water necessary for a comfortable water supply. In this case, the operation of the pump unit occurs in automatic mode. If the parameters of the upper and lower pressure are correctly set on the relay, then the pump will operate in the optimal mode without overloads, which in turn will extend its service life and protect it from premature wear.

Where to install?

In order for the device to function correctly, the connection of the pressure switch to the pumping equipment must be performed in such a way that its surges and turbulence can be avoided. That is why the best place is located nearby with a hydraulic accumulator.

Before starting the installation of the sensor, it is worth studying the manufacturer's instructions regarding operating conditions. The thing is that some products are allowed to be used only in rooms with heating.

When connecting the unit to a submersible pump to supply water to the house, the following equipment is mounted in front of the relay:

- well pump;

- supply pipeline;

- check valve;

- shutoff valves;

- drainage into the sewer system;

- filter device rough cleaning water.

If a pumping station with surface pumping equipment is used to equip an autonomous water supply system, the installation of the sensor for the pump is even simpler. In this case, a block installation is performed, that is, the relay is mounted in combination with the pump product. Such a pump is equipped with a special fitting for connecting the sensor. In addition, such models usually use a built-in check valve and a coarse water filter.

Sometimes a relay can be connected directly to a submersible pump if the hydraulic tank is located in a caisson near a well or directly in a well. In this case, the sensor is used in a waterproof housing, which can be used in conditions of complete immersion under water.

Attention: the choice of sensor mounting method depends on the features and model performance. Usually the preferred mounting method is indicated in the product manual.

The electrical automation of the water system and the relay itself can be connected in different ways, but usually one of the two common circuits is used. In any case, it is necessary to strictly follow the installation sequence and first connect the sensor to the water supply system and only then can it be connected to the electric network.

The first way is the easiest. It involves the installation of a relay on the main pipeline. It is important to follow the recommendations and installation rules from the accompanying documentation for the product. Installation is done using a tee that connects to the adapter fitting. An outlet hose can be used instead of a fitting.

The second method is implemented using a special nozzle with five outputs. The following equipment is attached to it:

- a supply pipe coming from a water source;

- sensor;

- device for measuring pressure (manometer);

- pipes for supplying water to the house;

- hydraulic tank.

After installing the sensor on the fitting, the product is connected to the pumping equipment and connected to the power supply.

Whichever method you choose, when connecting the product, you should adhere to the following installation recommendations:

- All threaded connections constituent elements of the water supply system must be carefully sealed. To do this, you can use tow, special sealant or FUM tape.

- To properly connect the relay, it must rotate freely on the fitting. However, an American connector can be used instead.

- To connect to the power supply network, it is necessary to use a cable, the cross section of which is selected depending on the power of the pump. Since pumping equipment with a capacity of not more than 2 kW is used to solve the problems of autonomous water supply of a country house, a cable with a cross section of 2.5 mm² is enough.

- As a rule, the terminals of the device should be marked to facilitate its connection. If there is no such marking, then the purpose of each terminal can be found in the circuit diagram supplied with the equipment.

- If the product comes with a grounding terminal, then grounding of the device must be performed.

Relay Performance

The main sensor parameters that must be correctly configured and on which the efficiency of the autonomous water supply system depends are as follows:

- Lower pressure. This indicator regulates the lower pressure limit in the hydraulic tank, at which a comfortable pressure is provided at the far point of consumption and pump equipment starts up.

- Top pressure. This parameter controls the upper pressure redistribution at which water stops to accumulate in a completely filled hydraulic tank. That is, the relay turns off the pumping equipment.

- Pressure difference. This is an indicator that indicates the difference between the upper and lower pressure set on the relay. Normally, this difference should be 1.4 bar.

Relay setting

To configure the relay, you must perform the following sequence of actions:

- We drain the water from the system by opening the lower tap. Open the cover on the pressure switch.

- We launch pumping equipment for water injection.

- When the pump shuts off, you need to detect and record the pressure gauge. This will be the maximum indicator.

- Now open the tap farthest from the pumping equipment or the topmost in the system. After a certain amount of water flows out, the pump unit starts up again. You need to record and record the pressure gauge at this moment. So you know the lower pressure. Now you can find out the pressure difference your sensor is configured for. To do this, subtract the bottom from a larger indicator.

- If the pressure of water from the upper or the most distant tap does not suit you, then you need to adjust the lower pressure by increasing it. To do this, the equipment is disconnected from the network and the nut is pulled on a large spring. To reduce the pressure, we do the opposite.

- If the pressure difference setting that you found does not fit the standard of 1.4 bar, then it must be set again. To increase the pressure difference, tighten the nut on the small spring more tightly, and to reduce the difference, on the contrary, weaken the compression force of the small spring.

Video instruction for installing and configuring a pressure switch:

In any suburban area that is not connected to the central water supply system, the owners first of all equip a well or other similar source of water. Then a pump is lowered into it, which will allow to extract fluid from the well and do it quite productively.

However, do not forget how serious automation plays for well pumps. After all, without it it is impossible to establish an autonomous water supply system in the house.

1 Features and purpose

The automatic control unit plays a huge role in the arrangement of the entire water supply system of any private house. Without it, people would have to spend incomparably more time on completely basic things.

2.1 The first generation of automation

The first generation of these devices include the simplest automation and individual devices. They cannot organize the fully autonomous functioning of the water supply system, but this is not required from such devices.

The first generation automation includes:

- Float switches;

- Dry running locks.

On the principle of operation of the pressure switch, much has been said above. This simple automation unit is convenient for its cheapness and practicality. The relay rarely breaks, it is easy to configure, and in case of failure it can be quickly replaced.

The only problem with it is that in addition to the relay, you will have to buy a hydraulic accumulator. This control unit will not be able to cope with the tasks set by itself.

2.2 The second generation of automation

The second-generation control unit is already a much more serious mechanism. This implies the use of an electronic device with several sensors. These sensors are mounted directly in the pipeline, on the pump and in several other places.

All information from the sensors is transmitted to the microcircuit, which controls all the processes that are associated with ensuring the operation of the water supply system.

The electronic unit is convenient for its practicality and a large number of functions. For its normal functioning, it is no longer necessary to buy a hydraulic accumulator, since automation responds to changes in pressure in the system in real time. As soon as the tap turns on somewhere, the sensor immediately responds to a pressure drop.

When lowering it to a certain level, he immediately gives a command to the pump, and he pumps water until the valve is closed and the pressure in the system is normalized.

As you can see, the principle of operation is largely similar to the principle of the pressure switch, but here we are already getting rid of the extra link in the system and optimizing the operation of all its elements.

In addition, electronic components are often equipped with additional functions:

- Temperature control;

- Emergency shutdown;

- Blocking dry running;

- Fluid level control.

And this is not all of their features. Of the minuses of such devices, one can note their great tendency to breakdowns, the need for fine tuning and an increased price.

2.3 The third generation of automation

The latest generation control units include truly powerful and reliable systems. They are very expensive, but they work out their money. In fact, this is all the same electronic automation, but with an expanded amount of function.

One of the main ones is the possibility of fine control of the pump motor. The fact is that almost any household pump is equipped with an unregulated engine. Rather, you can adjust it, but not with your own hands. It works in one mode and at the same speed. In most cases, this is quite enough, but not always.

![]()

It should be understood that very often the pump engine does not require so much effort to pump fluid. For example, if someone in the bathroom just opened the tap for a few seconds, then standard electronic automation will immediately start the pump at full capacity. Although, by and large, such efforts were not required of him.

But the pump during operation uses a lot of electricity and consumes its resource. You can solve this problem if you install the control units in question.

Automation of the third level not only starts the pumping equipment at the right time, it also regulates the level of voltage of electricity that is supplied to its engine.

Thus, you will be able to better control the operation of the pump, reduce the wear of its engine and significantly reduce energy costs.

Also, automation has all the known functions of direct and emergency control, perfectly protects the device from power surges and other similar troubles.

Plus, it can be programmed according to several work algorithms, which is also very useful. Especially if you have a non-standard water supply system with its own nuances.

2.4 Features of connecting automation for pumps

Connecting automatic control units is not at all difficult. However, there are several nuances here. If we talk about devices of the first generation, then they need to be mounted rarely. As a rule, installation is necessary only for a pressure switch, since it is purchased separately.

Dry-float switches and interlocks most often are built in at the pump assembly stage. In some cases, they will need to be connected before immersing the sample in the well. But the connection process here will only consist in connecting several terminals and sealing them.

The pressure switch is mounted on the accumulator. It must already be pre-configured by rotating the large and small nuts. The first is responsible for the upper pressure limit, the second for the pressure difference.

Connection steps:

- We assemble the entire system, install a hydraulic accumulator.

- We attach a pressure switch to it.

- We connect all the elements.

- We connect the device to electricity, if necessary.

- Set the top position of the relay.

- Adjust the difference between the upper and lower position.

- Testing the system.

- If necessary, reconfigure some provisions.

Electronic control units alone are not recommended. They are too complicated, they need to connect many sensors, fine-tuning, and they are very decent. Better entrust this work to a professional.

2.5 Overview of the automation unit for borehole pumps (video)

Automation for a submersible pump is installed to regulate the flow of water and smooth operation in a well or well. Thanks to this scheme, a country house, cottage, farm and other structures are provided with a reliable source of centralized water supply.

For the purchase and self-installation of automation for pumps, you need to know the principles of this mechanism, and most importantly - the submersible pump must be under water.

1 Instead of introduction: types of pumps

Two types of submersible or downhole equipment are divided:

- Vibrating.

- Centrifugal.

An ordinary well pump is designed for a depth of up to 10 meters. A deep pump for lowering into a well or a deep well functions when immersed up to 50 m. Water pressure is required for operation, therefore, depending on the type of model, there are recommendations for immersion.

Vibration pumps are extremely common in water wells. Centrifugal devices are used on farms and in private sectors. This is due to the ease of operation and installation, stable operation and low price. The principle of operation is the rotation of the blades. They create a centrifugal force that raises the pressure inside, pushing the water through the pipe.

Vibration system deep pump They are popular among technically savvy people, it is more convenient to use and more productive. Such pumps carry out cleaning of water and wells, they work in polluted environments. Therefore, when choosing the equipment necessary for water supply, first of all, pay attention to them.

The scheme of work is as follows - under the influence of amperage, a magnet is magnetized, attracting the armature. Because of this, the rubber piston bends, reducing the pressure, filling the chamber with water. When water touches the coil, the latter is demagnetized, the piston returns to its original position, increasing the pressure in the suction chamber. Water is pushed into the discharge chamber. When the water recedes from the coil, it is magnetized again and the rubber piston, bending, again creates a pressure drop, pushing water from the discharge chamber into the pipeline.

1.1 Pumps with pressure sensor

A pressure switch is required to regulate the flow of water. Thanks to it, the pressure inside the pumps and automatic shutdown or inclusion are measured. It is directly connected to the accumulator, which is filled thanks to the automation of the submersible pump. When the pressure drops, the relay turns on the submersible pump for the well, when filled with water, the pressure rises. When it reaches the mark set in the settings, the relay disables operation.

The relay is connected to the submersible pump system before being connected to the power supply. The device is connected to the water supply in a specially installed place. If the manufacturer did not provide for this, then connect it through a brass inch tee ("herringbone"). A similar accumulator connects both the accumulator and the manometer (pressure meter). Sometimes relays have a non-standard socket, so it is worth studying and, if necessary, get a brass adapter. The threads must be sealed to prevent leakage and breakage.

It is connected to the mains in several stages:

- two groups of contacts on the pressure sensor are determined, which open at maximum pressure;

- when choosing a cable, they are guided by the power of the pump;

- the ground wire is connected to the relay through specific screws. The ground symbol on the screws is indicated by the inverted letter T with two additional horizontal stripes;

- the conductors of the mains wire are connected to the contacts by each separate pair of contacts on the pressure sensor. In no case can they be combined;

- relay contacts are connected to the pump, observing the color of the wires. You can connect them to ground wires, but this is not necessary.

Checking the operation of the relay: turn on the pump for the well with automatic equipment and follow the pressure gauge. As water is withdrawn, pressure will increase. Upon reaching the maximum point, the relay will shut off the pump. If water is consumed (you can turn on the tap or hose), then the pressure drops and, again, at a certain point, the pressure switch turns the pump back on.

2 Automatic submersible pump settings

Automation of water intake provides easy access to water, but problems arise with the setup. Factory settings are suitable for most pump users. However, there is a need to change them, which requires:

- Disconnect the water supply system.

- Drain the water until the pressure gauge shows zero.

- Turn on the electricity in the water supply system.

- Switch the pump on again and monitor the pressure increase.

- At the moment when the relay switches off the pump, record the pressure on the pressure gauge.

- After that, drain the water again until the automatic system starts the pump.

- Lock on pressure.

- Clean the filters.

Only after these manipulations do they begin to configure. The relay has two springs. Large regulates the maximum value, while small - the difference between the maximum and minimum. To set the maximum pressure value, tighten the large relay spring. If you want to adjust the minimum value, tighten the nut on a small spring. To reduce the pressure value, the nuts are lowered.

2.1 Dry run protection and float switches

Dry running - the so-called operation of a submersible pump without enough water. This occurs due to clogging, violation of the tightness of the pipe and due to lack of water. By choosing the right model and calculating the dynamic change in water level, you can avoid the last problem.

Other breakdowns can be eliminated by regular inspection and cleaning. There are relays with an additional dry run protection function. To do this, produce special floats and press controls using automation.

Float switches are suitable for a well or a voluminous water tank. Some of them are designed to limit overflow, so you should carefully familiarize yourself with the model before setting. Those floats that prevent dry running are equipped with contacts that open when the water level drops. The cable installed on the float is placed so that the water level is sufficient when it is turned off (the motor did not work on dry run).

Press control is suitable for submersible pumps if they are used infrequently. The control unit automatically turns on the equipment when the tap is opened and off when the tap closes. Depending on the settings, it turns off when the pressure drops to 1.5-2.5 bar.

2.2 Automation for a submersible pump: protection against dry running and overload (video)

2.3 Principle of operation of the accumulator

This is a tank installed in the system for regulating pressure and storing water. Accumulator goals:

- increasing the life of the pump, due to the fact that it turns on less often due to the water reserves in the tank;

- maintaining constant pressure in the pipeline;

- protection against water hammer;

- water supply even during a power outage and other malfunctions.

Inside the hydraulic accumulator tank there is a membrane dividing it into two parts. The first stores water, the second air or nitrogen. The membrane is made of butyl, a rubber material that is hygienically suitable for storing water and can withstand significant pressure. Thanks to this material, water does not come into contact with the metal of the tank walls. In some models of hydraulic accumulators, a valve for bleeding air is provided, in others such a valve is installed independently.

The electric pump supplies water to the hydraulic accumulator tank until the diaphragm expands and the pressure sensor in the air chamber disconnects the relay. During the intake of water from the tank, the pressure drops, and the sensor turns on the automation. The pump with pressure sensor is adjustable. The accumulator is connected to the submersible pump control unit.

2.4 Aquareobot pumps

Pumping systems and surface pumps Aquareobot are equipped with the necessary devices. Therefore, you do not need to buy additional relays, flow sensors and hydraulic accumulators. Aquareobot is automated and tuned to a different frequency of use, just select a model.

Aquareobot protects against voltage, pressure, and water fluctuations. Aquareobot is equipped with internal automatic dry-running protection systems, even if the electric pump breaks down. There are Aquareobot models with adaptive pumping stations small volume - 2 and 5 liters and a universal station of 24 liters.

2.5 Connecting the automation unit to the pump

Independent strapping of the automation unit for submersible and submersible pumps requires power calculations. Therefore, it is better to pre-purchase equipment of one company, designed to connect with each other.

There are three main types of automation units; how you connect the unit and how to set the correct pressure settings in it depends on the type. Share:

- control unit in the form of a remote control;

- press control;

- pressure control unit.

The first type is connected to a pressure switch. Sometimes it can be installed directly to the float switch. It is necessary to buy additional protection against dry running, the connection of a pressure switch to a submersible pump and other elements. Some automation units already contain all protective elements. Press control provides the most reliable and multifunctional protection. The latter type is primarily designed for systems where strong pressure drops cannot be tolerated.

The automation control unit for the submersible automation pump is installed between the water intake point and the accumulator. An arrow is indicated on the body, which must coincide with the movement of water. When using a powerful pump (with a pressure of more than 10 bar), a pressure reducer should be installed in front of the automation unit.

The submersible pump is connected to the mains and the automation unit by fastons. The screw regulates the minimum pressure, as a rule, it is 1.5 bar. For sealing, the use of Teflon tape is recommended.

A country house, ideally, should have a level of arrangement no worse than in a city ordinary apartment. And in order to equip a country estate with your own hands without the involvement of specialists, you need to carefully plan everything and work hard.

A big problem is the creation of a decentralized water supply. But even when the necessary water supply system is ready, the problem remains to create an automatic mechanism for its operation, in particular at the level of the pump system. Consider an example of how automation is created for a submersible pump.

1 Types of modern submersible pumps

Before proceeding directly to the consideration of automation, you need to understand the popular varieties of pumps. There are two types of submersible pumps in total:

- Centrifugal.

It should be understood that any of the above automatic submersible pumps are installed exclusively in the liquid that they pump. Although the name "submersible" speaks of this, far from everyone understands this simple truth.

Among other things, many buyers mistakenly believe that submersible pumps are better than surface models, but this is by no means the case. The specifics of the operation of these two types of pumps are the same, but the mechanism of operation is different, as well as the conditions in which they are used.

Submersible pumps, for example, are used in wells with great depth, where it is necessary to achieve an increase in the water pressure in the pump in order to be able to pump it up.

But it must be remembered that submersible pumps are capable of operating at depths of up to ten meters, while deeper diving values \u200b\u200brequire more highly specialized pumping systems. Surface models are not capable of pumping water from such relatively large depths.

As regards exclusively submersible pumps, the most popular and popular vibration pumps are used for working in water wells, while centrifugal pumps are used extremely rarely for such purposes or to create water supply in the agricultural sector.

In vibratory devices, the main structural element is the membrane. Under the action of the vibration mechanism, it is deformed, which subsequently leads to a pressure difference, the final effect of which is pumping water in the right direction. Pumps operating on this principle have the three most popular brands in the CIS countries:

- Aquarius;

- Gardena.

In conditions where the soil is heavy, it is necessary to install the vibrating device as low as possible so that during its operation the well does not break down and is contaminated with various foreign objects from the soil. Moreover, vibration models are best placed in general only in fortified sources.

It is important to remember that under conditions of deep immersion of the device in the sludge, it is most acceptable and correct to dismantle the device during its operation. Fortunately, the devices of the brand "Aquarius", "Gardena" and "Kid" are easy to assemble and disassemble, which can be done with your own hands.

2 Types of automation for submersible pumps

There are three main types of automation for submersible pumps. They are presented as follows:

- Automation unit in the form of a control panel;

- Press control;

- Control unit with a mechanism to maintain stable water pressure throughout the system.

The first option is the simplest automation unit, which is able to protect the pump from possible voltage drops and are so frequent during operation pumping device short circuits. To ensure a fully automatic mode of operation, an automation unit of this type must be connected either to a pressure switch or to a level switch.

In some cases, it is possible to connect to a float switch. The price of such an automation unit on average does not exceed 4000 rubles. But there is a nuance. The fact is that without a pressure switch and special additional protection of the pump against possible dry running, the automation unit is practically useless.

And this is an additional cost of money, which in the amount of 4000 rubles is clearly not enough. There is, however, a unit with the listed systems embedded, such as Aquarius 4000, but its cost is more than 4000 rubles and reaches the mark of 10 thousand rubles. This unit is easy to install with your own hands even without consulting with specialists.

The second option, the so-called "press control", has built-in automation systems for the pump and passive protection against dry running. Management in such an apparatus is based on several parameters, among which the level of water pressure and water flow are taken into account.

For example, if the water flow in the device exceeds the mark of 50 l / min, then the device in the current mode, naturally under the correction of press control, works continuously. In the event of a reduction in water flow or an increase in pressure, press monitoring after a period of time specified by the parameters (up to 10 seconds) turns off the pump, which is a dry run protection system.

In cases of increase or liquid flow in the system, which does not exceed the mark of 50 l / min, the device is started when the pressure in the entire system is reduced to 1.5 atmospheres.

Such a function is most important for conditions of a sharp increase in pressure, where it is necessary to reduce the number of shutdowns and turns on the pump with minimal water flow.

This, moreover, has a positive effect on the operation of the accumulator. For conditions of a sharp and powerful increase in water pressure in the device, up to 10 atmospheres, an automatic shutdown of the device is provided.

The most successful examples of press-control devices include the BRIO-2000M model, the price of which is not more than 4000 rubles, and the Aquarius brand device, the price of which is from 4000 rubles to 10 thousand.

The price of a backup accumulator for devices of the Aquarius and BRIO brand of this type does not exceed 4000 rubles. When purchasing this type of automation (both the Aquarius and BRIO brands), it should be noted that installing it with your own hands is somewhat harder than the previous version.

The third option, and it is the last one, is a control unit with a mechanism to maintain stable water pressure in the entire system. This mechanism is primarily needed where a sharp increase in pressure cannot be allowed. And this is necessary because in cases of a constant increase in pressure, the energy consumption increases and the efficiency of the pump as such decreases.

The absence of a sharp increase in pressure and the constancy of the fluid transfer system is achieved due to the rotation of the rotor of the electric motor of the device, while the speed control is automatic. Control units of this type are represented by the brands "Aquarius" and "Grundfos".

The relatively low cost of automation for pumps and the simplicity of their installation with their own hands attracts the buyer, and they immediately begin to install everything themselves. But few people know that the automation installed on the equipment for deep diving, requires the presence of an electronic kit.