Grundfos pump selection program. Grundfos Pumps Short Description

Company Grundfos produces the widest range of pumping equipment in several segments:

- Heating, ventilation and air conditioning

- Industrial equipment

- Water supply and sewerage

Wet rotor pumps, in-line pumps, monoblock and cantilever pumps. Delivery up to 2000 m3 / h, head up to 140 m.

CR multistage pumps and installations based on them, cantilever pumps. Delivery up to 2000m3 / h, head up to 480 m.

Household and industrial well pumpshousehold pumps and mobile automatic stations water supply, pumps for drainage and sewage, automatic domestic and industrial sewer installations. Delivery up to 12,600 m3 / h, head up to 650 m.

Dosing pumps. Productivity is up to 990 l / h, a pressure is up to 180 m.

Feature of heating system pumps Grundfos

The words "heating circuit" themselves contain features.

So, if we say “circuit”, then we mean a circulating (closed) system.

If we say “heating circuit”, we mean high temperature.

If the system is circulating, what makes up the pressure? Of course from hydraulic losses.

And for what is the expense

For the compensation of heat losses in heated areas, that is, the amount of heat transferred to the room.

If the boiler has night mode, the pump must be installed on the supply line. If the boiler has a night mode, then it lowers the temperature of the coolant. Switching between day and night modes occurs through the coolant in the flow line of the heating system.

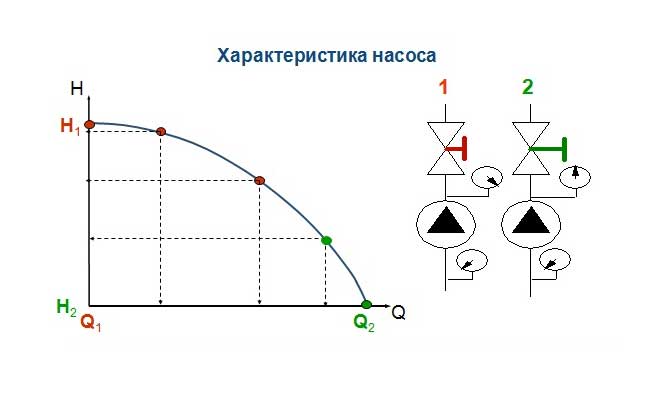

Type of pressure characteristic centrifugal pump they are obtained by changing the pressure and flow parameters mutually influencing each other due to a change in the flow cross section of the pressure pipe from completely closed (the flow is zero and the pressure is maximum) to completely open without the pressure pipe (maximum flow and the pressure is zero).

So get a series of points on the graph - the pressure characteristic of the pump, exclusively experimentally.

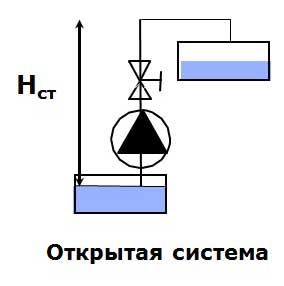

Systems are open(there is a si connection, therefore, the static height parameter must be taken into account)

Closed (there is no connection with the atmosphere and therefore static pressure, in a certain sense, can be neglected).

Open systems are used in water supply systems when water needs to be supplied for distribution. Closed systems are used in ventilation and air conditioning where circulation is present.

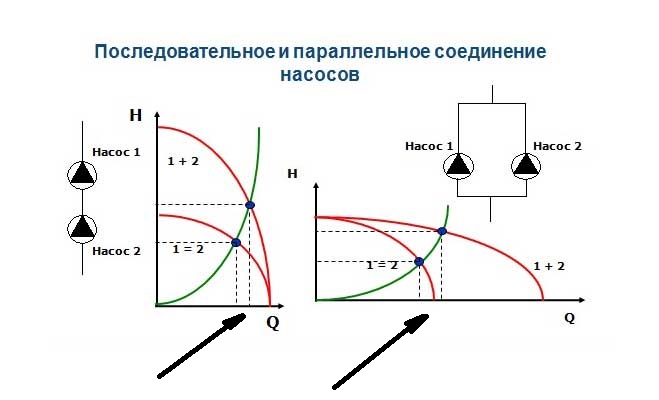

Most systems use multiple pumps at once. There are two types of pump connections - serial (used for very high heads, for example, with reverse osmosis) and parallel (most often used in systems with redundancy and cascading).

With the simultaneous operation of several pumps, depending on the type of connection, the overall pumping characteristic looks as shown in the figure above.

It should be noted that it is often forgotten that doubled parameters in flow and pressure are possible only at the extreme points of the characteristics, in fact, in the working zones of the pumps only an increase in these parameters occurs, but not a doubling. In any case, it is required to build a characteristic of the network and search.

That's all I wanted to describe in this article; we will describe each pump in detail separately.

- A modern and fast program for self-selection of Grundfos pumps online!You do not need to download and install anything on your computer!

This service will provide you with a complete list of Grundfos equipment (including discontinued models).

A huge library of the Grundfos company, in which you can find the answer to any question and even more.

All service documentation is now in one place! Instructions, video on assembly / disassembly, a list of spare parts and much more.

Is your pump obsolete and out of production? Go to the "Replacement" section, where you can pick up an analogue, as well as get recommendations.

In the "Drawings" section, you can see the dimensions of any pump and look at its 3D model.

Grundfos pumps selection online

Grundfos drainage pumps are designed for pumping clean water as well as for dirty and wastewater with solid particles up to 10 mm in size. They are used in everyday life, in construction, at industrial facilities. Depending on the scope of application, it is possible to select Grundfos pumps online based on the wishes of the customer. Our managers are ready to offer you a wide range of services for the purchase of a suitable pump model - so you can get not only an extensive consultation, but also make an online selection of the Grundfos pump according to the parameters that are of decisive importance for your choice.

Grundfos drainage pumps are equipped with an integrated thermal switch, and the shut-off chamber is filled with grease. In addition, in such pumps there is no cooling casing, since the engine is constantly washed and cooled with hydraulic fluid during operation. Grundfos pumps are also very compact, which is an additional advantage for convenient transportation and installation.

The selection of the Grundfos pump online begins with the determination of the appropriate modification of the installation, based on the maximum possible particle size of the pumped dirty water. Depending on this indicator, pumps may be designed for:

- pumping water from various tanks at industrial facilities;

- pumping domestic wastewater;

- pumping wastewater from sedimentation tanks and treatment facilities in construction.

The selection of the Grundfos pump is carried out taking into account the required operating option: manual or automatic operation.

However, regardless of the model you choose, all Grundfos pumps have the following advantages:

- long term of operation;

- strength and resistance to external influences;

- the ability to successfully pump fluid with any inclusions - both solid and fibrous;

- compact sizes.

How to choose a pump for a well by pressure and flow?

Choosing a pump for a well is not an easy task, because in order to choose a suitable installation, a number of factors must be taken into account:

- well depth - measured, as a rule, using a staff;

- average water level in the well;

- water column height - the difference between the depth of the well and the water level in it;

- dynamic level (at which water, when pumping out of the well, begins to decrease);

- the diameter of the rings of the well - to determine the total volume of water;

- water quality - allows you to determine the percentage of impurities and solid particles in the composition of water;

- maximum and average volume of water - to select a pump of the appropriate capacity.

Based on all the criteria that affect the choice of installation for a well, our experts are ready to offer you the selection of a pump for recruitment and flow rate online, which will save you time and make the process of finding the right option comfortable and convenient.

To choose the right water pumps for summer cottages, seasonality should be taken into account. So, the choice of pumping equipment for the summer season is much wider than the range of universal pumps. The presence of a pressure storage tank in the pump structure is also important. It performs the function of protection against water hammer, and is also used as a reserve source of water in emergency situations. Automation of the pump is ensured by pressure.

Choosing a heat pump for a boiler: important nuances

The selection of a heat pump for the boiler is a responsible measure, since this device is designed to provide the process of heating a house or heating water in a boiler. It is most expedient to carry out the selection of the pump according to the power of the boiler. So, the smaller the diameter of the heating pipe, the greater the power the pump must use.

Speaking about the advantages of heat pumps, it should be noted their efficiency, which is achieved due to the high efficiency coefficient. So, consuming 1 kW of electricity, such a device produces four times more heat, which is especially nice, given the lack of fuel costs. Other advantages of heat pumps include absolute fire safety and environmental friendliness. An additional argument in their favor is a long service life of up to 30 years, as well as minimal maintenance costs.

Experience tells us that you can optimize a project of any complexity in 70% of cases. Often, total savings reach 25-30% of the budget. In view of these impressive numbers, the company "Hydrolance" introduces to the market free service . The service includes detailed calculations / recalculations when selecting equipment, optimizing and modernizing the project, offering cost-effective analogues, as well as delivering equipment on time.We offer:

Significant savings due to the selection of analogues;

Reduced time spent on selecting Grundfos pumps and other equipment;

Optimization of delivery schedules and shipments of equipment;

Reduce costs:

Call us and let us know if you want to use this service, or use the ONLINE application form. After a preliminary discussion of the project, send us the necessary documentation - equipment questionnaires, specifications, tech. connection conditions and an explanatory note.

After clarifying all the details, we develop our technical and commercial offer (TCH) and send it to you.

The specification of the TCH compiled by us is absolutely identical to the design one. Any replacement of equipment is justified from a technical and economic point of view. All replacements and configurations are supplemented by comments. We will explain all the details of the selection of new equipment and the proposed modernization of the project.

We conduct a comprehensive audit:

When checking the correct selection and operation of equipment, we will identify:

Errors and inaccuracies in the selection of equipment;

Inappropriate or inconsistent use of equipment and components;

Discontinued products and parts;

The ability to reduce the cost of additional purchases of additional components.

We optimize the project:

For the optimal selection of equipment in accordance with the technical requirements of the project, after the audit, we will select the best equipment for each individual facility. Design documentation is developed by us in accordance with applicable regulatory documents and to the extent necessary for approval. During optimization, modern computer technologies and specialized application packages are used that ensure the accuracy of engineering calculations, budget documentation and the quality of the graphic display of project documentation. When selecting, first of all, the price-quality ratio is taken into account, and equipment with the minimum delivery time or from the warehouse is also selected.

With a comprehensive order of equipment, we provide significant discounts.

In addition to major savings, this guarantees delivery of the object on time or ahead of schedule.

We deliver on time:

When planning the delivery schedule, we make an accurate calculation of the dates of receipt of equipment. Compliance with deadlines and control are carried out at all stages of delivery.

Warranty service of the supplied equipment is carried out by our Service-center - certified service partner of companies GRUNDFOS, ALFA LAVAL, Reflex.

We remind you that the service "Audit and optimization of projects" absolutely FREE. For all questions related to this service, please contact us: