Household pumping stations jilex jumbo for home and garden. Gileks pumping station will help private owners

Pumping station water supply provides the necessary pressure and pressure of water in the pipes in front of sanitary appliances. A properly selected and mounted station will work for a long time, without breakdowns and the replacement of expensive equipment. But sooner or later, the working parts of the pumps break down, undergo corrosion, and the identified cause of the failure in time will save time and money on the replacement of new equipment.

Many problems in the pumping station are eliminated independently, without contacting the service center. Before we learn about the causes of a breakdown or incorrect operation of the pumping station and how to eliminate them, we will get acquainted with the very concept of “pumping station”, the principle of its operation, types of pumps and its composition.

How to independently identify and eliminate

malfunctions in pumping stations?

Consider common breakdowns and malfunctions in the operation of pumping units that occur during operation, causes and methods for troubleshooting with your own hands.

The pump unit rotates and water does not flow

Causes of the operation of the pumps "dry" occurs when an air plug is formed in the pipeline. This occurs if the installation rules are not followed. The slope of the pipeline should be directed from the pump to the source of water supply.

In order for the pumping station to start pumping water again, check for leaks in the pipes and clean the suction line of the pump.

Another reason for the lack of water in the pumping station is the depleted water supply (reservoir). In this case, turn off the pump until the source is replenished.

Cause:

- no water;

- height of absorption is more than 7 meters;

- air has accumulated in the suction line of the pipeline;

- valve clogged.

Remedy Method:

- fill the pump with water;

- reduce the suction height of the pump;

- remove air from the suction pipe;

- clean the valve.

The pump in the station starts up too often and supplies jerky water

Most pumping stations have membrane tanks. Frequent switching on and off of the station is associated with damage to the membrane tank or insufficient pressure in the water supply network. For normal operation of the station, it is necessary to replace the membrane tank. Sufficient pressure in the network is checked by a manometer.

The reason for the breakdown:

- the membrane in the expansion tank is damaged;

- foreign objects in the pump.

Remedy Method:

- replace the expansion tank membrane;

- remove foreign objects from the pump housing.

The pumping station works, but the water comes in jerky, intermittently

Interruptions in operation occur due to air leakage through leaks in pipelines and connections. Check for cracks and leaks and replace pipes or fittings if necessary.

The pump constantly pumps water without interruptions or shutdowns

The reason is the poor or inaccurate setting of the pressure switch, most likely it is set to too much pressure in the network. By adjusting the relay to a lower working pressure, the problem will be solved.

Water or wastewater station does not turn on

The pump station usually runs on electricity, there is no power supply to the pump, the other reason is that the impeller of the pump is jammed or the fuse is blown. It is necessary to inspect the pump, to check whether the station is correctly connected to the electrical circuit.

Failure can occur during breakdown of the motor winding, and the smell of burnt insulation appears. In this case, it is better to replace the engine completely.

Cause:

- no power supply;

- fuse breakdown;

- the impeller is broken.

Remedy:

- pump cleaning

- rotate the fan impeller;

- check wiring diagram;

- check pressure switch;

- check capacitor.

The pump device (impeller) does not rotate and makes a hum

A long idle time of the pumping station leads to a hum of the motor. This occurs either from the attachment of the motor rotor to the inner surface of the housing, or the capacitor in the terminal box has failed. You can correct the defect manually by disassembling the housing and moving the rotor.

Repair of the pumping station Gileks, Jumbo

Fault Repair:

- wire burnout - replacement with new wiring;

- lack of shaft rotation pumps in the Gileks pumping station - replacement of a capacitor;

- motor winding short circuit - replacement of wires;

- insufficient water pressure - this is a violation of the joints and pipe connections or a malfunction in the check valve.

Grundfos pump station repair

Grundfos Company It has a large service center, where they repair any complexity of pumps and electric motors. Without contacting the manufacturer's service center, you can independently replace bearings, gaskets and sealing joints.

The most common cause of failure of all grundfos pumps - poor alignment of the alignment of the shafts during installation and installation.

Common Causes of Breakdowns

Common causes of breakdowns, which should be checked first, are as follows:

- lack of power supply;

- lack of liquid / water in the water supply network;

- malfunction of the pump itself;

- failure of the diaphragm / expansion tank;

- damage to the automation unit

A few words about adjusting the pressure switch

R  barely pressure is a device that automates a pumping station. The relay regulates the pressure in the water supply network, which is supported by the accumulator. Therefore, the pressure switch and the accumulator are always paired.

barely pressure is a device that automates a pumping station. The relay regulates the pressure in the water supply network, which is supported by the accumulator. Therefore, the pressure switch and the accumulator are always paired.

The unit with pressure switch responds when the tank is full or empty. The manufacturer makes the “default” setting (minimum pressure 1.5 atmospheres and 2.5 atmospheres maximum pressure).

After connecting the relay to the pump, the relay is configured for a specific object (the set water pressure in the system by technologists).

Setting up the relay for an individual project:

- The relay case is opened, where the relay control nodes are located. The minimum pressure is regulated by tensioning a large spring, and the maximum - by tensioning a small spring.

- The adjustment of the "minimum" pressure begins on an empty storage device. Why just turn off the pump and open the water taps. Then loosen the large spring. Then turn on the pump and gradually tighten the spring. As soon as the pump starts to supply water, the large spring is no longer touched, the minimum pressure becomes equal to the pressure of the air mass.

- Differential pressure adjustment is even easier. The pump is turned off and the pressure value on the relay is measured. If the result is not satisfactory, the large or small spring is again adjusted. Then the pump is switched on again and the maximum pressure value is measured.

Principle of operation

Depending on the type of the working part of the pump, the principle of rising water differs.

Consider the types and brands of pumps:

- Water wheel. It works like a water mill by scooping up water with blades.

- Archimedes screw. Water rises with a special screw lifting device - an impeller.

- Piston pump. Pumps of this type are used for pumping water from mines, summer cottages.

- Vane pump. This is one of the varieties of a piston pump. It is used for pumping water, oil and fuel.

- Bellows. The principle of operation in pressing a special "accordion", which produces a pumping liquid. Low price. Simple construction.

- Centrifugal pump. The most common type of pump. Works due to centrifugal force. Inside the pump there is an impeller with blades that spin and eject water from the center to the periphery.

- Jet pump. Pumps water through compressed air or steam.

The device of the pumping station

Below is a pumping station and its main equipment:

Types of water pumping stations

With integrated ejector

The principle of operation is based on the rise of water due to the created discharge. The rise is carried out from a depth of 20 - 45 meters. The pumping station has great performance. Due to the high noise level, such a station should be located in the basement.

With remote ejector

A pump with this type of ejector is immersed in water with two pipes at once. Water entering the ejector leads to the appearance of a suction jet. This type of pump is susceptible to sand blockage and corrosion.

Ejectorless designs

In these pumps, water rises using a multi-stage design. They operate silently and consume little power.

Purpose of the pumping station

What are water supply units intended for? This is pumping water to the consumer from a source of water supply (well, river, tank), and for this a special pump-up device is needed.

It is the pumping unit takes water through suction pipelines and transfers it to a residential building or industrial building through pressure pipelines. No water supply system will work without pumping units.

Need pumps for supplying water for drinking needs, for extinguishing fires, pumping domestic and industrial wastewater, drainage of mines and basements, borehole and sand pumps. There are pumps for pumping solutions, feces, clean water, oil products. The selection of the type and brand of pump is made for each specific case.

Popular models: al ko (alko), grundfos, gardena 3000 4, grundfos, jileks jumbo 60 35, marina, whirlwind, etc.

The composition of the pumping station

The complete set of the pumping station is as follows:

- Pump unit. The main parameters for selecting an individual pump or a finished pump installation are the required water flow (in cubic meters / hour) and pressure (in meters).

- Pressure accumulator. It is a metal tank in which water pressure is constantly maintained. As soon as the water is drawn, the pressure in the tank drops and the pumps turn on. When the pressure in the tank reaches the maximum set point (water withdrawal stops, and the pump continues to work), the pumps are turned off.

- Automation unit. Without automation, it is difficult to imagine a modern pumping station. It was the pump automation system that made it possible to reach a new level of comfortable existence.

- Pump station is installed on a foundation plate with vibration isolating inserts;

- On the suction pipe install shutoff valves and pressure gauge;

- On the pressure pipe install shutoff valves, check valve and pressure gauge;

- Use quick couplings;

- All connecting seal parts;

- Suction pipe lay with a slope from the pump;

- Distance from speakers parts of the pump to walls and other equipment not less than 700 mm;

- Water station must be securely fixed to the base;

- Tank water level or the water supply should be 500 mm above the pump axis.

Pump fixing

- The pump should be installed on a flat surface and close to the water supply. The length of the suction lines of the pump must not exceed 20 meters.

- Supply and exhaust ventilation should work in the pumping station (maximum room temperature should be 40 ° C.

- The distance from the external walls and other equipment to the pumps must be at least 700 mm, it is necessary for the convenience of maintenance and repair.

- Before installing a water pump station at the installation site, it should be noted in advance where there will be holes for fasteners.

- After installing the pumping station check that there are no excessive stresses in pipelines and fittings. This will prevent leaks and accidents.

What are the benefits of automatic

pumping stations?

Work automation pumping station allows you to provide comfortable living conditions with a minimum of worries. More recently, the operation of the pumps was regulated manually, a constant human presence was required. Now all the main work is done by an automatic system that does its job perfectly.

Automatically adjustable water flow, gate valves are controlled, pumps are switched from working to standby when one of them breaks, and many other technological processes.

Conclusion

Thanks to the types of breakdowns described in the article and tips for eliminating them, each person will be able to independently identify and fix them at home without calling the wizard, while saving money.

Russian design - Jumbo pumping stations - an ideal device for providing water supply to residential buildings, small farms. Units are also used for pumping industrial water used for irrigation of gardens, household plots. Easy to install and operate, the devices are compact in size and, thanks to mobility, can be installed in any convenient place.

The device and principle of operation of Jumbo

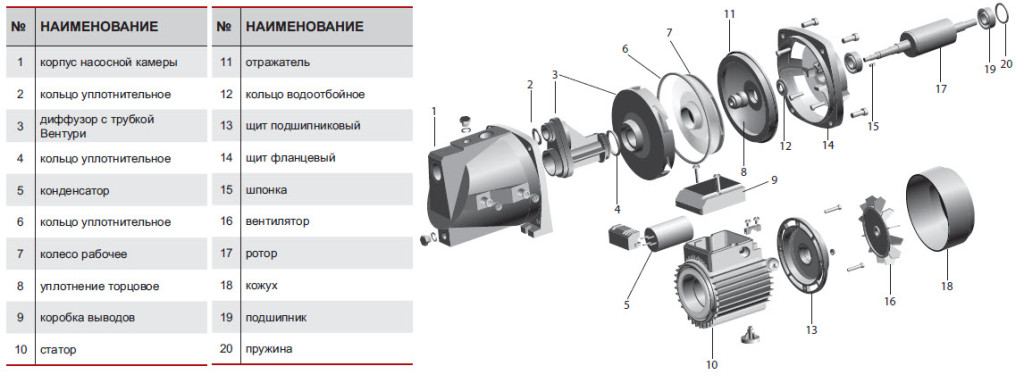

Pumping stations of this type include the following components and components:

- Water pump, equipped with an electric motor for supplying water from any source;

- Storage tank with a capacity of 20 liters;

- A relay-type device for turning on / off the pump, depending on the level of water pressure in the tank;

- Pressure gauge.

Completely tight design excludes moisture hit on electric knots and devices. When choosing Jumbo pumping stations, it is necessary to remember the casing marking indicating the material of manufacture:

- N - the body is made of stainless steel;

- P - glass-filled polypropylene material;

- H - cast iron alloy.

The impeller of the devices is made of hardened moisture-resistant plastic, which is not subject to abrasion and has the property of resistance to aggressive compounds in the water stream. The design tank withstands significant water pressure, and by means of a nipple located on the side, air pressure can be forced.

The principle of operation of Jumbo pumping stations is simple:

- The water intake part of the structure is equipped with a check valve that creates a column of water and does not allow the flow to flow back into the well. A non-working closed state is alternated with a working open when water from the source fills the storage tank;

- As soon as the faucet opens in the house / watering tap, water enters the pipes under pressure and flows out of the tap;

- As the amount of liquid and pressure decreases, the design pump is turned on, and the pump pumps the required amount of water into the tank;

- After closing the tap, the device does not stop until the tank is full to the required level, then it automatically turns off;

- In the event of an emergency and the inability of fluid to enter the system, the unit also shuts off automatically until the troubleshooting is complete.

Thus, the Jumbo station provides an uninterrupted supply of water in the right volume and quantity. With a complete power outage, water from the tank will still flow through the pipes, but injection into the tank will not occur. It turns out that the larger the storage tank of the structure, the more water the user will be able to stock. This is especially important for farms where power outages are a fairly common occurrence.

Jumbo pumping stations: lineup and features

The brand is represented by a sufficient number of units to meet the needs of each owner.

NS Jumbo 60/35

This is an automatic pumping station, shown to provide local water supply in private households. Features of the model:

- Work with mines up to 9 meters deep, where water temperatures are + 1- + 50С;

- Automatic flow pressure control system;

- Uninterrupted functionality;

- Low energy consumption;

- An automatic device to stop the engine when there is a risk of overheating;

- Durability;

- Low price from $

Specifications:

- Supply 60 l / min;

- Head 35 m;

- Case material - cast iron;

- The volume of the tank is 24 liters.

Jumbo 70/50

A station is used to provide water supply in houses, cottages and in summer cottages. The power of 1100 watts allows you to create good pressure and deliver the flow over a long distance, but the tank capacity is only 24 liters, which is a drawback. However, the equipment with an injector and the execution of steel, cast iron or plastic are design advantages. Features of this model pumping station are as follows:

- Constant flow pressure;

- Soft start eliminates water hammer;

- Automation for protection against voltage surges in the network;

- Reliability and durability provide a long service life;

- Price from $

Important! This model is ideal for small farms and mini-factories. But it is worth remembering the small volume of the storage tank.

Jumbo 50/28

One of the most popular models of the product line used for local water supply of houses and mansions. Specifications:

- Power is 500 watts;

- Tank capacity 24 liters;

- Rise to 9 meters;

- Head 3 m3 / hour;

- Price from $

The Jumbo pumping station of this model is indicated for providing water supply to small houses. The maximum distance of water supply is 28 meters. Not differing in its technical features, the design has a low energy consumption and reduced price value.

Installation of stations

When purchasing a Jumbo pump design, there is no need to call a master, it is extremely simple to install it:

- A check valve is attached at the junction of the suction pipe;

- Using an open reservoir as a source, it is better to install a non-return valve at the end of the pipe;

- The suction hose or pipe should not have differences in height, rising to the structure gradually;

- It is necessary to locate the Jumbo pumping station in a ventilated room in the cold season, in the open air in warm seasons. Do not allow condensation on the body, as this can lead to corrosion of the fasteners;

- The connections must be checked for leaks in order to minimize air leakage into the intake pipe;

- Providing a grounding outlet will eliminate the risk of fire. The current strength of a working Jumbo pump station is up to 5 amperes.

The Jilex Jumbo pumping station is superficial. The equipment has a built-in ejector, which is connected to the pipes. The system contributes to the efficient intake of liquid at the inlet, in addition, the equipment does not have a requirement for the purity of the liquid and dissolved gases.

Reviews about the features of the models of pumps "Jumbo"

Gileks pumping stations, reviews of which you can read below, are presented by models 60/35 P and 70/50 P, which have a polymer body, and embedded threaded parts are made of brass. Pumps 60/35 N, 60/45 and 70/50 have a stainless steel housing, while on the 60/35 model this part is made of cast iron. According to users, some parts, including the impeller, are made of plastic materials, they are highly durable.

The Gileks pumping station, the malfunctions of which can be eliminated by you yourself, has a transitional aluminum flange closed by a cover, which is why its contact with water is completely excluded. Buyers emphasize that the equipment is well protected from leaks, this is ensured by the use of graphite ceramic seals.

The device operates due to an electric motor, which is a short-circuited system with components. The stator is protected by a thermal protector, the latter takes on the function of emergency blocking. As buyers emphasize, this component turns off the engine if the winding overheats. The pump station "Dzhileks" is able to maintain the necessary pressure by turning off and on the device depending on the flow rate. Units can be divided according to the principle of management. For some, the principle of automation is laid down, they have a surface accumulator, a pressure switch and a manometer. The volume of the accumulator in this case is 24 liters. If we are talking about a pump brand 70/50 P-50, then this figure is 2 times more, since a horizontal hydraulic accumulator with a volume of 50 liters is installed there. Model 70/50 N-50 HOUSE is equipped with a powerful controller, which guarantees effective management.

Review of positive qualities

The pumping station "Dzhileks" has many advantages, among them are:

- reduction of starting currents;

- minimization of mechanical loads;

- lack of water hammer at the time of inclusion.

It should be noted and reliable protection against voltage surges, as well as the lack of dry running. A certain pressure is established in the pump and maintained during operation at a given level. Dry running is eliminated thanks to the automation unit, which controls the flow rate. Here the threshold pressure value is laid.

Characteristics of the pump brand "60/35 H-24"

This pumping station "Dzhileks" is intended for surface installation, an additional function is the increase in pressure. The maximum head is 30 m and the throughput is equivalent to 3.3 m 3 / h. The power consumption of the device is 600 watts, the suction water must be clean, the size of the filtered particles is 0.8 mm. Permissible fluid temperature may vary from 1 to 50 ° C.

The equipment is equipped with a built-in ejector, which is supplied as a unit. The hydraulic tank has a volume of 24 liters, as for the diameter of the outlet, this parameter is 1 inch. The power cord ensures convenient operation of the pump, its length is 1.5 m. The pump must be installed horizontally. Permissible ambient temperature is 1 ° C and above. You can not be afraid that this pump station “Jilex Jumbo” will overheat, because the system has protection.

Characteristics of the pump "60/35 P-24"

This model has a maximum head of 35 m. The throughput is 3.6 m 3 / h. The equipment operates from a network voltage of 220/230 V. Power consumption is 600 watts. The outlet diameter of the equipment is 1 inch. The ambient temperature during operation of the device can vary from 1 to 35 ° C. Water level control is electronic automatic.

Overview of the pump brand "70/50 P"

This pumping station "Dzhileks Jumbo" costs 7500 rubles. and is intended for use in a garden. The equipment must be installed on the surface. The device combines the benefits of centrifugal pump and the practicality of a self-priming model. The unit is adapted to operating conditions in Russia, where voltage fluctuations are frequent. Moreover, the quality of the intake water may be different, in addition, a certain volume of gas may be contained in it. This equipment is intended for supplying water from reservoirs, wells, wells, reservoirs and tanks.

Specifications Model 70/50 P

If you are interested in Jilex Jumbo pumping stations, it is recommended to read reviews about them before visiting the store. The 70/50 P model, whose power consumption is 1100 watts, is no exception. This garden pump has a capacity of 3.9 thousand l / h. The maximum suction depth is 9 m, but the height of the water supply is 45 m. The device weighs 9.85 kg. The equipment has an automatic system that provides independent switching on and off, while the pressure will be maintained at a certain level. This ensures continuous operation.

The pump can be operated at a wide temperature range, but the temperature of the pumped water can lie in the range from 1 to 50 ° C. These pumping stations "Dzhileks Jumbo", reviews of which are often quite positive, have an asynchronous squirrel-cage motor, a pressure gauge and a hydraulic accumulator. The use of graphite ceramic seals eliminates leakage from the pump. In the manufacturing process, materials are used according to the type of glass-filled polypropylene, which forms the basis of the body. Embedded threaded parts are made of brass, but the basis of the wheels is plastic material. The Venturi Guide Tube provides productive and stable operation over a long service life.

Repair Features

Despite the fact that the described equipment has high quality, it may be necessary to repair the Gileks pumping station. If you notice that there is a rumble in the engine, and the equipment is choking, all this can cause problems with the impeller or engine. Disassemble the device and inspect it yourself. If the impeller is cracked or the bearings are out of order, they can be replaced with new ones and the device can be assembled in the reverse order.

- NS - pumping station;

- series - Jumbo;

- productivity - 60 l / min

- injection distance 35 m, or into the tank to a height of 3.5 m.

- case - cast iron;

- the accumulator capacity is 24 liters.

The considered pumping station Gileks is popular among summer residents. Installation is economical, consumes 600 watts. Its capacity is enough to provide a family of 4 people, the cost is about 6 thousand rubles. But water is not enough if you need to organize watering the garden.

The pump station Dzhileks Jumbo 70 50n 50n is a more powerful installation that meets the needs of a rural farmstead. This model is called Gileks HOUSE. The housing may be made of stainless steel, plastic or cast iron. Users say fiberglass is no less durable material. The HOUSE tank model is distinguished by a 50-liter battery, the increased power is 1100 watts and a powerful controller that ensures the system is working.

The pump station Gileks Jumbo 50/28 is small, ideal for organizing water supply for small families. But a weak pump cannot work for a long period, it is not intended for irrigation. The station costs only 3600 rubles.

The manufacturer provides users with a large selection. This is mainly a variation of Jumbo stations:

- 75 n 5 n,

- 75 n 24 n,

- 70/50 n-50 with a horizontal tank and others.

Difficulties operating equipment

A system assembled in accordance with all the rules will work reliably. And in order to carry out installation in accordance with the requirements, you need to study the instructions of the Gileks pumping station. Recommendations for connecting equipment will help the competent installation of the station:

A system assembled in accordance with all the rules will work reliably. And in order to carry out installation in accordance with the requirements, you need to study the instructions of the Gileks pumping station. Recommendations for connecting equipment will help the competent installation of the station:

- The intake pipe installed in the intake should not touch the sand cushion, hang above it at a certain distance. The pipe rises to the pump smoothly, without sagging, in which air can accumulate.

- The head with the ejector is covered with a sand screen. A check valve is mounted at the top. All joints on the suction line must be airtight.

- Discharge port connects to receiver

- A power outlet is installed, always with grounding.

Automation devices are set up at the factory stand, if necessary, it is better to contact specialists if you need to change the parameters.

The operating instructions for the Gileks pumping station describe the main malfunctions and how to solve them.

If the pump works and water does not flow, the cause is air entering the suction system. It is necessary to check if the check valve is not passing, and if there is water in the well. Often air sucks through leaks at the joints.

If the pump works and water does not flow, the cause is air entering the suction system. It is necessary to check if the check valve is not passing, and if there is water in the well. Often air sucks through leaks at the joints.

If water enters the system jerky, the pump often turns on, the membrane may have broken or the relay has failed. Due to a malfunction of the relay, the pump may, and in general, not be switched off.

If it doesn’t turn on, check the condition of the power outlet, the presence of energy in the network. In the instructions of the pump station Gileks you can find the answer to many questions. It also describes self-repair and recommendations to contact the nearest service center.

Spare parts for pumping stations Gileks not difficult to find. And their cost is not high. If repairs are made in the workshop, they will take 500-600 rubles for the work, taking into account the complexity. But spare parts should be purchased additionally. A battery tank can cost from 900 rubles, a membrane - 400, and a pressure switch above 600. All units are sold in specialized stores or repair shops.

Presented by the manufacturer Jileks in the Jumbo series provide the consumer with the opportunity to organize an independent water supply system that will use its own resources - sources located on the site.

Jumbo pumps: design features

- case made of high strength materials:

- in models 60/35 P and 70/50 P the case is polymer and brass and embedded parts;

- 60/35 N, 60/45 and 70/50 N - stainless steel;

- 60/35 - cast iron.

- wear-resistant plastic impeller;

- aluminum adapter flange, closed with a plastic cover, excluding its contact with water;

- graphite-ceramic sealants to prevent leakage;

- an electric motor - a short-circuited system that includes numerous components;

- a starter protected by a thermal protector that performs emergency blocking.

The Jumbo series are characterized by the following models as the most popular:

- With automated pressure control (modifications 60/35, 60/35 P-24, 60/35 N-24, 70/50 P-24, 70/50 N-24). The equipment of this plan is equipped with a surface pump, a hydraulic accumulator, a manometer, a pressure switch and a 24-liter hydraulic accumulator.

- Pumping stations 70/50 P-50 and 70/50 H-50, equipped with a 50-liter hydraulic accumulator.

- Modifications 70/50 P-50 HOUSE and 70/50 H-50 HOUSE are equipped with a powerful surface pump and controller, which contributes to effective management.

Advantages of Jumbo Pumps

A series of Jumbo pumps is represented by several model lines, and despite the fact that they have some structural differences, the stations are ready to demonstrate a lot of advantages compared to their analogues:

- the presence of a soft start: reduces inrush currents, eliminates water hammer at startup, minimizes mechanical stress;

- functionality: Jumbo pumping stations provide uninterrupted supply of water from tanks.

- the ability to set and maintain the optimal pressure parameter;

- lack of "dry running";

- exception of overload from currents;

- effective protection against voltage drops;

- economical power consumption.

Jilex Jumbo in our store

The online store site is an official dealer of the Russian factory manufacturer Dzhileks.

Here you can buy Jilex Jumbo pumps, as well as choose accessories for it, with home delivery in Moscow and Moscow Region (delivery in Russia is carried out by transport companies). All products purchased in our store have an official guarantee.

The catalog contains a large selection of Jeelex models, if you need advice, you can call us or ask a chat question, we will be happy to help you.